Contents

1 Safety Precautions............................................................................................................................1

1.1 Transport...................................................................................................................................1

1.2 Storage.....................................................................................................................................1

1.3 Installation.................................................................................................................................2

1.4 Operating..................................................................................................................................2

1.5 Maintenance .............................................................................................................................3

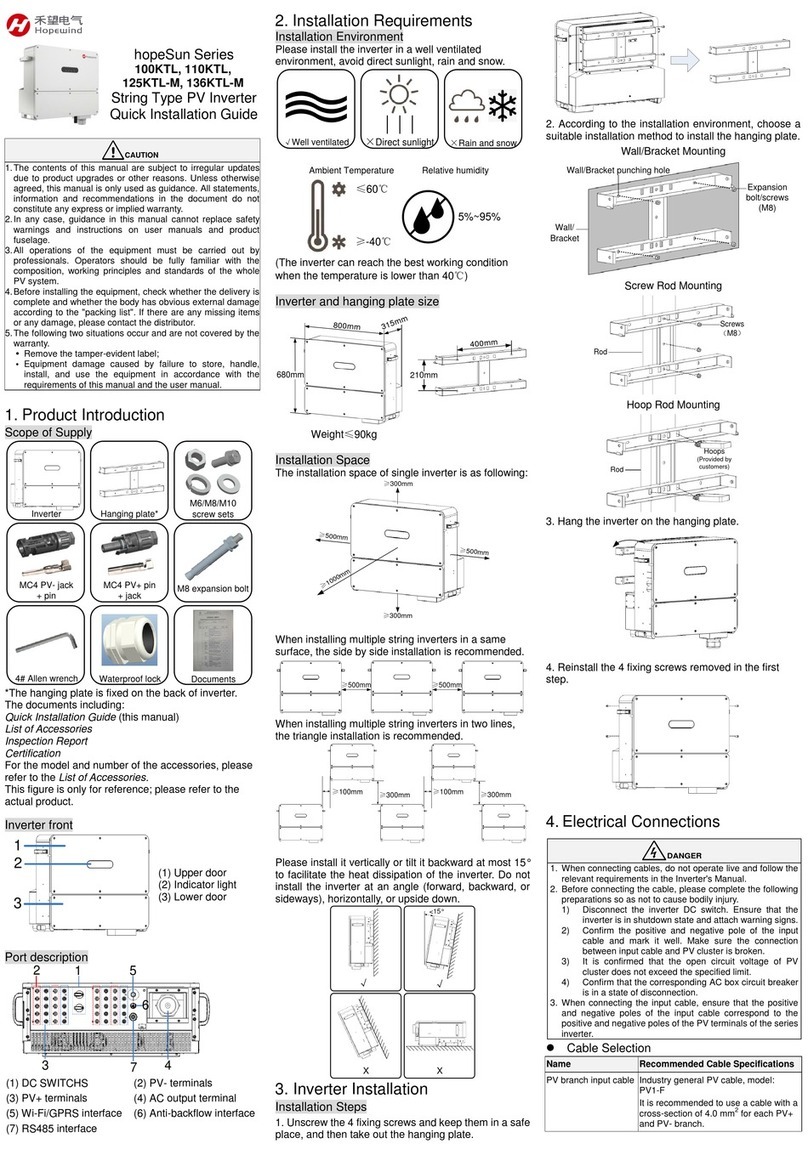

2 Product Description..........................................................................................................................5

2.1 Product Introduction..................................................................................................................5

2.1.1 Schematic...................................................................................................................................5

2.1.2 Operating mode..........................................................................................................................7

2.2 System Configuration and Application......................................................................................8

2.2.1 Application Description................................................................................................................8

2.2.2 Supported grid form....................................................................................................................9

2.3 Naming Rules ...........................................................................................................................9

2.4 Nameplate label......................................................................................................................10

2.5 Machine configuration.............................................................................................................10

2.6 Identification on the package ..................................................................................................12

2.7 Warning Labels in Inverter......................................................................................................13

2.8 Technical Data........................................................................................................................14

2.9 Mechanical Parameters ..........................................................................................................16

2.10 Environmental requirements.................................................................................................17

3 System Installation..........................................................................................................................19

3.1 Unpacking Inspection..............................................................................................................19

3.2 Installation Tool Preparation ...................................................................................................19

3.3 Installation Environment Requirements ..................................................................................19

3.4 Reserved Space Requirement................................................................................................20

3.5 Fixed method..........................................................................................................................21

3.5.1 Hoop Mounting.........................................................................................................................21

3.5.2 Screw Rod Mounting.................................................................................................................21

3.5.3 Bracket Mounting......................................................................................................................22

3.6 Electrical connections.............................................................................................................23

3.6.1 Cable requirements...................................................................................................................23

3.6.2 Cable Selection ........................................................................................................................24

3.6.3 Torque requirement ..................................................................................................................24

3.6.4 Preparation before operation.....................................................................................................25

3.6.5 Connecting ground ...................................................................................................................25

3.6.6 Open the lower door .................................................................................................................26

3.6.7 Connect the AC output cable ....................................................................................................26

3.6.8 Connecting communication cable..............................................................................................27

3.6.9 Connect the DC input cable ......................................................................................................28

4 Commissioning Guide ....................................................................................................................31

4.1 Check before starting..............................................................................................................31

4.2 Power-on system....................................................................................................................32

4.3 System shutdown....................................................................................................................32

5 Maintenance and Troubleshooting................................................................................................33

5.1 Maintenance project and cycle................................................................................................33

5.2 Troubleshooting......................................................................................................................33