Content

About this manual·················································································· 5

Content·································································································7

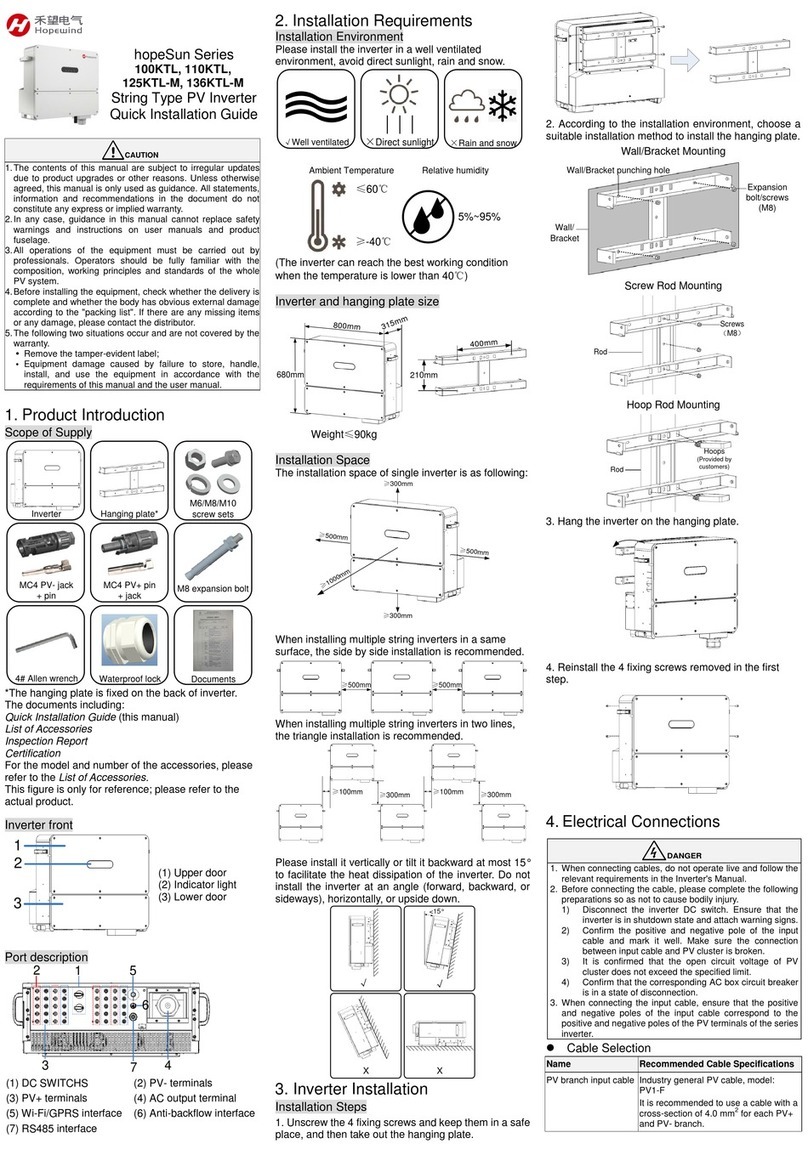

1 Safety Precautions··············································································· 1

1.1 Transportation·······················································································1

1.2 Storage ·······························································································1

1.3 Installation····························································································2

1.4 Operation·····························································································2

1.5 Maintenance·························································································3

2 Product Description············································································· 5

2.1 Product Description················································································5

2.1.1 Schematic Diagram··············································································5

2.1.2 Operation Mode···················································································5

2.2 System Configuration and Application·························································6

2.2.1 Application Description··········································································6

2.2.2 Supported Grid Form············································································ 7

2.3 Naming Rules·······················································································7

2.4 Nameplate label ····················································································8

2.5 Machine Configuration············································································9

2.6 Signs and labels·················································································· 11

2.7 Warning Labels in Inverter ····································································· 11

2.8 Technical Data ····················································································12

2.9 Mechanical Parameters·········································································13

2.10 Environment Requirements ··································································13

3 System installation ·············································································15

3.1 Unpacking and inspection······································································15

3.2 Preparation of installation tools ·······························································15

3.3 Installation environment requirements ······················································15

3.4 Requirements for reserved space····························································16

3.5 Fixing method·····················································································17

3.5.1 Pole-mounted (hoop) installation··························································· 17

3.5.2 Pole-mounted (screw) installation·························································· 18

3.5.3 Wall-mounted installation····································································· 19

3.6 Electrical connection·············································································20

3.6.1 Cable requirements············································································ 20

3.6.2 Recommended cable specifications······················································· 20

3.6.3 Torque requirements··········································································· 21

3.6.4 Preparation before operation································································ 21

3.6.5 Connect the PE cable ········································································· 22

3.6.6 Connect the AC output cable································································ 22

3.6.7 Connect the communication cable························································· 23

3.6.8 Connecting DC input cables·································································23

4 Commissioning Guide·········································································25

4.1 Check before starting············································································25

4.2 Power on the system············································································26

4.3 Power off the system············································································26

5 Maintenance and troubleshooting ························································27

5.1 Maintenance items and cycle··································································27

5.2 Troubleshooting···················································································28

6 Inverter handling instructions······························································33

6.1 Disassembly of the inverter····································································33

6.2 Replacing the inverter···········································································33

6.3 Packaging the inverter ··········································································33