Content

About this manual........................................................................................................................... 5

1 Safety Precautions.......................................................................................................................1

1.1 Transportation.....................................................................................................................................1

1.2 Storage................................................................................................................................................ 1

1.3 Installation........................................................................................................................................... 2

1.4 Operation.............................................................................................................................................2

1.5 Maintenance....................................................................................................................................... 3

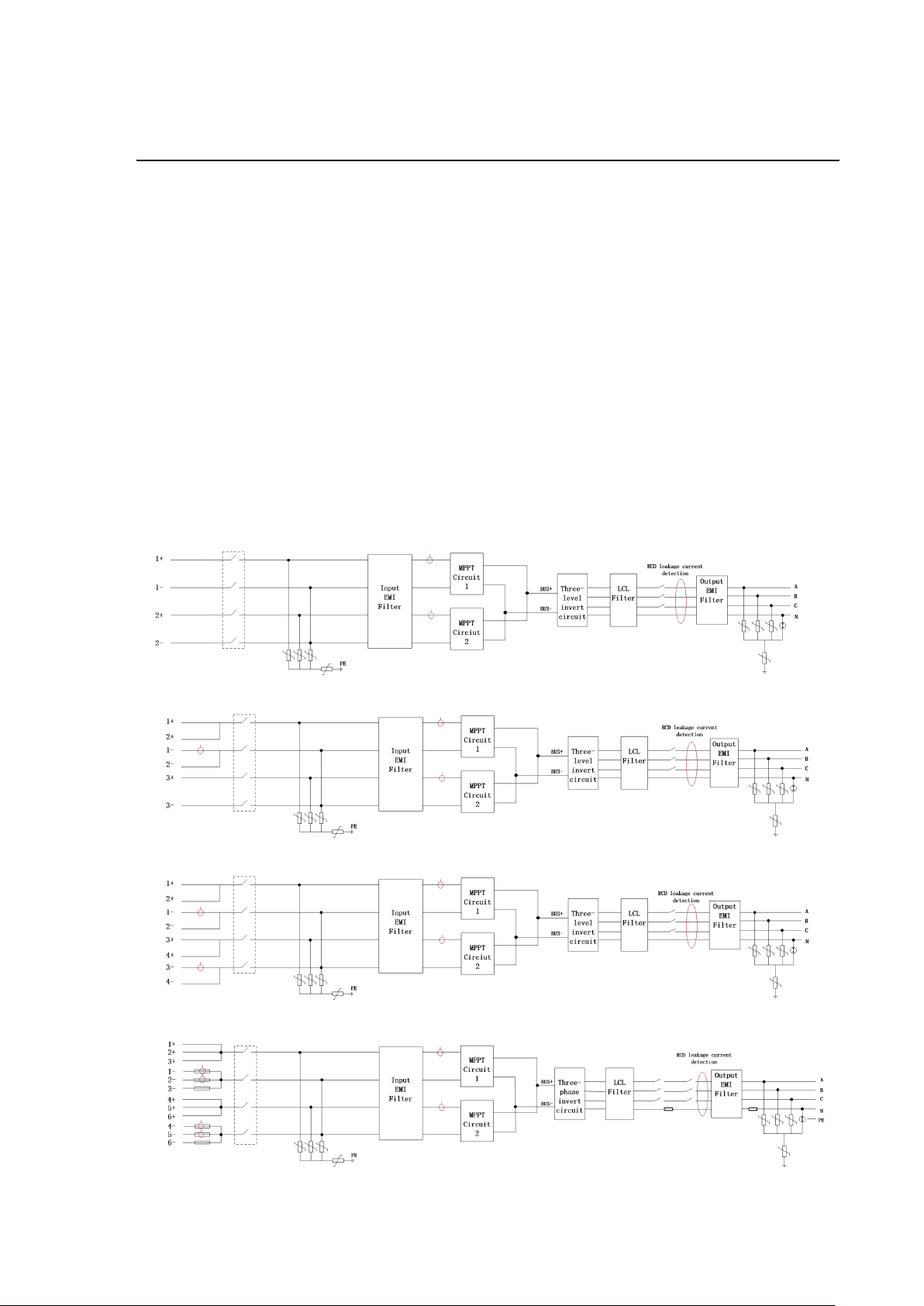

2 Product Description.................................................................................................................... 5

2.1 Product Description........................................................................................................................... 5

2.1.1 Schematic Diagram......................................................................................................................... 5

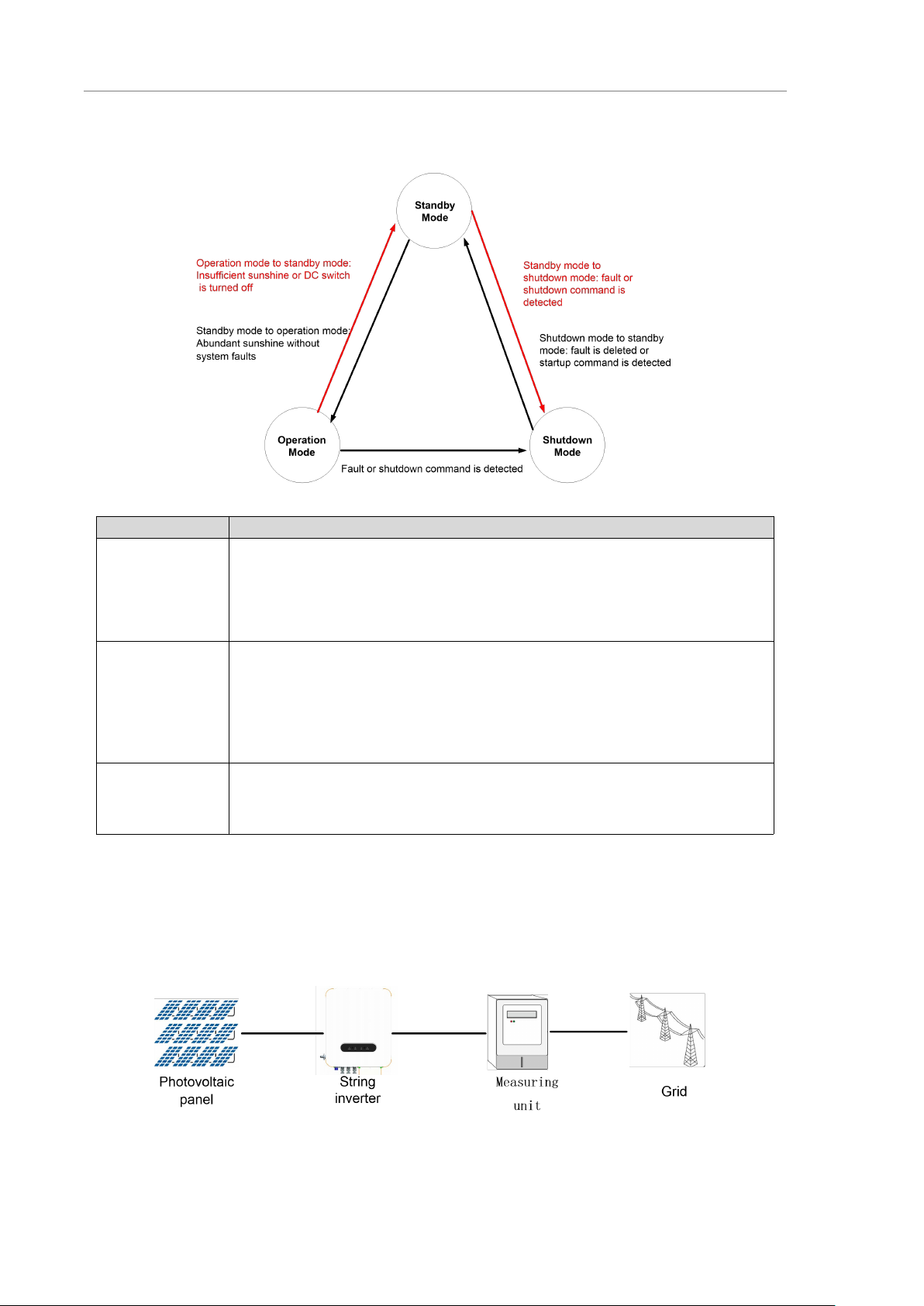

2.1.2 Operation Mode............................................................................................................................... 6

2.2 System Configuration and Application............................................................................................6

2.2.1 Application Description....................................................................................................................6

2.2.2 Supported Grid Form...................................................................................................................... 7

2.3 Naming Rules..................................................................................................................................... 7

2.4 Nameplate label................................................................................................................................. 8

2.5 Machine Configuration...................................................................................................................... 9

2.6 Signs and labels...............................................................................................................................11

2.7 Warning Labels in Inverter..............................................................................................................11

2.8 Technical Data..................................................................................................................................12

2.9 Mechanical Parameters.................................................................................................................. 14

2.10 Ambient Requirements................................................................................................................. 14

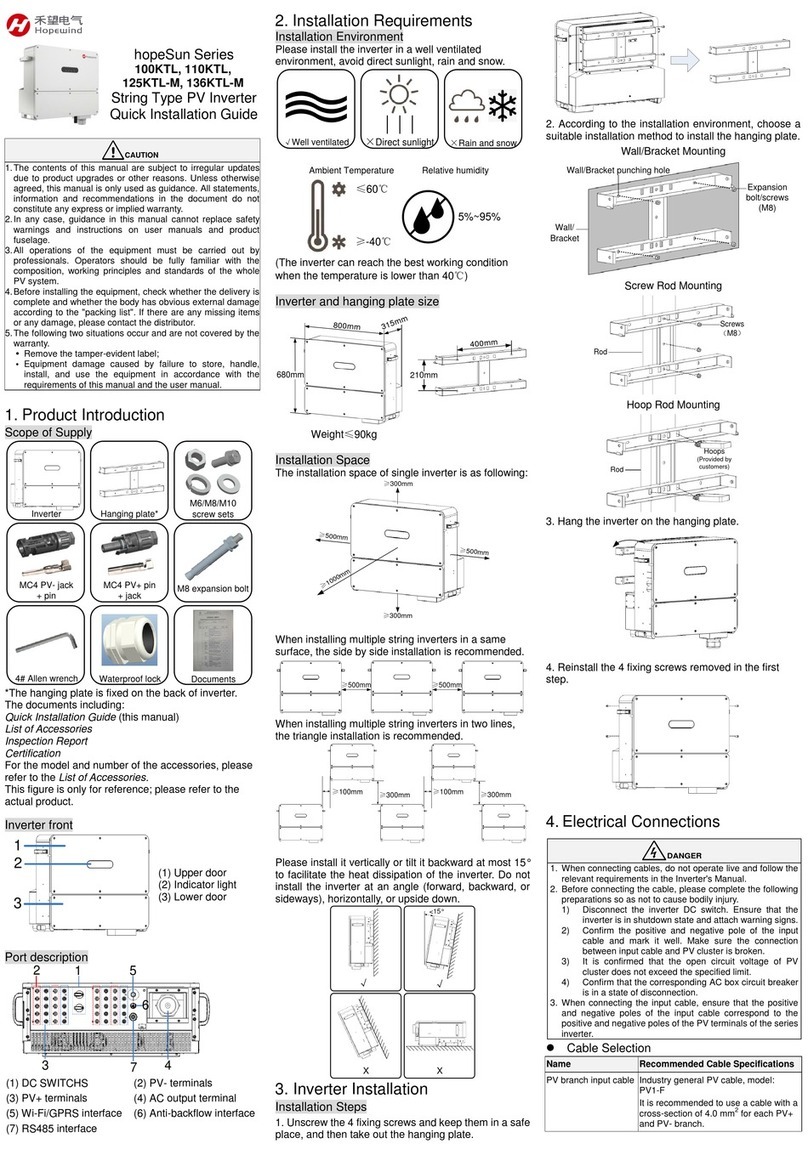

3 System installation.................................................................................................................... 17

3.1 Unpack and inspection....................................................................................................................17

3.2 Preparation of installation tools..................................................................................................... 17

3.3 Installation environment requirements......................................................................................... 17

3.4 Requirements for reserved space.................................................................................................18

3.5 Fixing method...................................................................................................................................19

3.6 Electrical connection....................................................................................................................... 20

3.6.1 Cable requirements.......................................................................................................................20

3.6.2 Recommended cable specifications...........................................................................................20

3.6.3 Torque requirements..................................................................................................................... 21

3.6.4 Preparation before operation.......................................................................................................21

3.6.5 Connect the ground wire.............................................................................................................. 22

3.6.6 Connect the AC output cable.......................................................................................................22

3.6.7 Connect the communication cable............................................................................................. 24

3.6.8 Connect DC input cables............................................................................................................. 25

4 Commissioning Guide.............................................................................................................. 27

4.1 Check before starting......................................................................................................................27

4.2 Power on the system.......................................................................................................................28

4.3 Power off the system.......................................................................................................................28

5 Maintenance and troubleshooting........................................................................................ 29

5.1 Maintenance items and cycle........................................................................................................ 29

5.2 Troubleshooting................................................................................................................................30

6 Inverter handling instructions................................................................................................ 35

6.1 Disassembly of the inverter............................................................................................................35

6.2 Replace the inverter........................................................................................................................ 35

6.3 Package the inverter....................................................................................................................... 35

6.4 Scrapped the inverter......................................................................................................................35