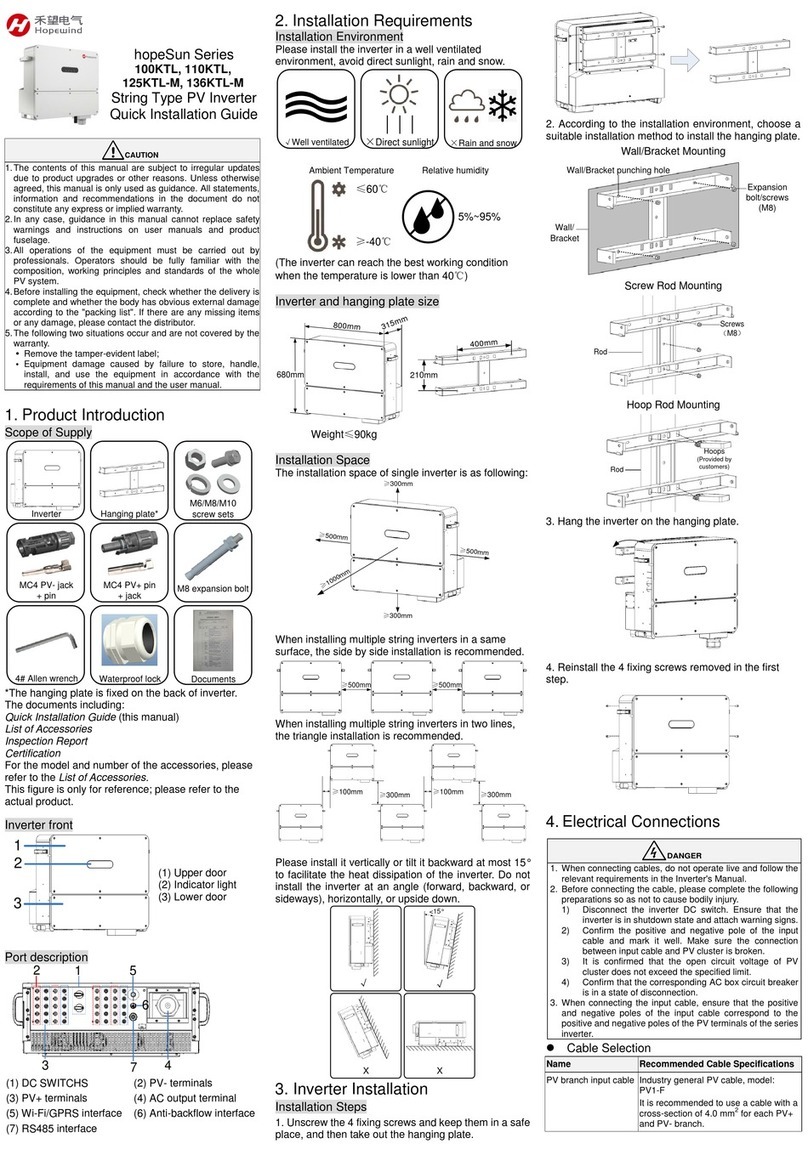

Cable Selection

Recommended Cable Specifications

Industry general PV cable, model: PV1-F

It is recommended to use a cable with a

cross-section of 4.0 mm2 for each PV+ and PV-

branch.

4 core outdoor cable (A, B, C, N) or 3 core

outdoor cable (A, B, C)

Recommended cross sectional area of

conductor (copper):35mm2

RS485

communication

cable

It is recommended to use a special

communication cable or 4-core or 2-core

shielded twisted pair cable with a

cross-sectional area of not less than 0.75mm2.

It is recommended to use at least one grounded

dedicated cable with a cross-sectional area of

16 mm2.

Note:

1. The AC output has only 1 waterproof locks with a specification

of 42mm~50mm. When the screw is locked, use the sleeve to

calibration.

2. The RS485 communication cable has only one waterproof

lock and the size is 18mm~25mm.

Output side cable connection

1. Crimping the OT terminal. Users need to prepare

the OT terminals themselves. The OT terminal

model of PE is M6, and the model of AC is M8.

1) Strip the front end of the cable core.

OT terminal

Cable LL+(2~3)mm

2) Put on the heat shrink tubing and OT terminal.

3) Crimp the OT terminal.

4) Move the heat shrink tubing forward to cover

the seam.

5) Use a dryer to heat the sleeve to make it tight.

2. Ground connection:

Note: The ground cable must be reliably connected to the

grounding bar.

3. DC output cable connection:

1) Remove the lower door by 4# Allen wrench.

2) Tear off the AC output protective film and

install the waterproof lock.

Put in the

waterproof

lock parts

and screw

them

together

3) Screw off the locking cap of the AC output

waterproof lock.

4) The AC cables are connected to A, B, C and

N of theAC terminal row in turn, and the

fastening torque is 8N*m. Fasten the locking

cap after completion.

PV Input Cable Connection

1. Crimp the MC4 terminal:

1) Confirm the positive and negative terminals of

the input cable and mark them.

Note: Please do not judge by the color of the cable

only, be sure to refer to the actual measurement.

2) Stripping with a wire stripper;

Stripping length

requirement

positive

negative

3) Press the cable together with the

corresponding core according to the correct

polarity.

Crimp

method

Positive

Negative

4) Insert the core into the male and female ends

of the MC4 connector and tighten the

connector back cover according to the correct

polarity.

2. Remove the sealing plugs of the input terminals at

the bottom of the inverter. Connect the positive

and negative terminals of each input cable to the

PV+ and PV- input terminals of the inverter one by

one. Insert it until you hear a "click".

3. If there are unconnected input terminals, please

confirm that the unconnected input terminals

remain sealed by the plugs.

RS485 Communication Cable Connection

On the RS485 adapter board X3, two RS485 interfaces

(labeled P2, P3) are shown. This interface is used to

connect adjacent inverters.

1. Crimp the 485 terminal. Users need to prepare the

terminals themselves, and the terminals model

needs to match the 485 cable selected.

1) Strip the front end of the cable core.

2) Insert the terminal and crimp.

2. Unscrew the RS485 waterproof lock and take off

the seal baffle.

3. Pass the RS485 cable through the waterproof lock

and connect it to the interface P2, P3 on the

RS485 adapter board X3. Tighten the locking cap

after completion.

P2

P3

P1

3PIN: 485-

2PIN: PE

1PIN: 485+

4. Reinstall the lower door panel of the inverter.

The connection of multiple inverters is suggested to be

connected in series in the following diagram.

1# inverter

X3

2# inverter 3# inverter

N# inverter

Data collector

Follow

this

mode

in

series

P3

P2 X3

P3

P2 X3

P3

P2

X3

P3

P2

485 interface

485 interface

5.Post-installation Check

1. Confirm that the inverter is securely installed in place

2. Check if the ground wire is properly connected,

whether the connection is reliable and secure, and

ensure that there is no open-circuit or short-circuit

3. Check that the output cable is properly connected, that

the connection is reliable and secure, and that there is no

open-circuit or short-circuit.

4. Check whether the DC input cable connection polarity

is correct, whether the connection is reliable and secure,

and ensure that there is no open-circuit or short-circuit.

5. Check if the RS485 communication cable connection is

correct and reliable.

6. Check if the inverter's lower door panel is replaced and

the door panel screws are tightened.

7. Check if the DC input terminals that are not needed are

sealed

6.LED indicators Description

Both PV side and grid side

are normal

Grid side is normal, PV side

is abnormal

PV side is normal, grid side is

not connected

Both PV side and grid side

are not connected

Inverter is not in operation

Communication is abnormal

Note:

Slow flash: 1 sec on, 2 sec off;

Flash: 0.5 sec on, 0.5 sec off.

©Copyright Shenzhen Hopewind Electric Co., Ltd.

Address: Building No.11, 2nd Industrial Park of Guanlong Village,

Nanshan District, Shenzhen, China

Tel:0755-8602 6786