Horst Welding Page 6

GENERAL SAFETY PRECAUTIONS

Careful operation is the best assurance against accidents. Itisthe owner’s responsibility

to make surethat alloperators read and understand this manual and follow the

recommendations, cautions and warnings before connecting to a prime mover and

operating the equipment.

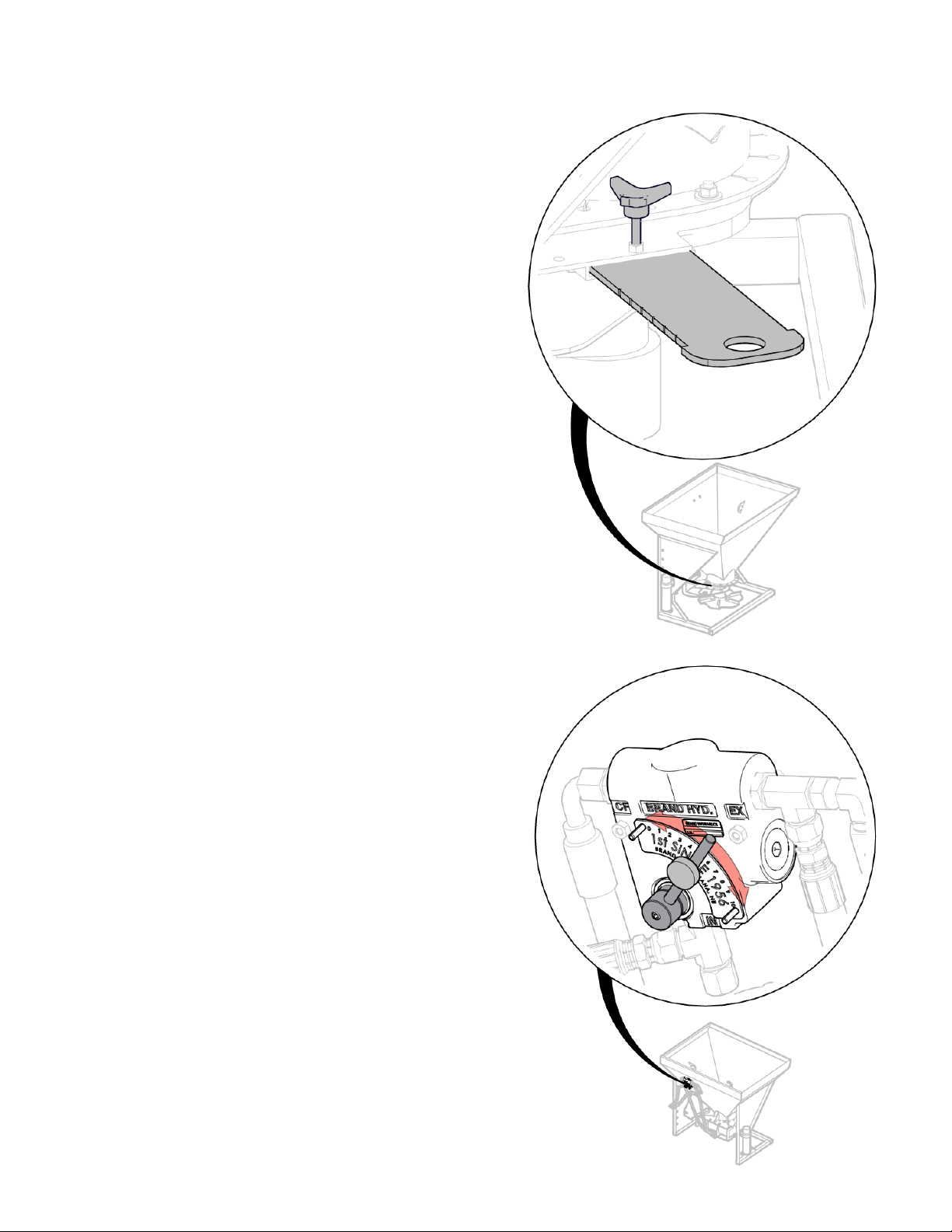

Familiarize yourself with all controls and know how to quickly stop the equipment and all

rotating parts in the case of an emergency.

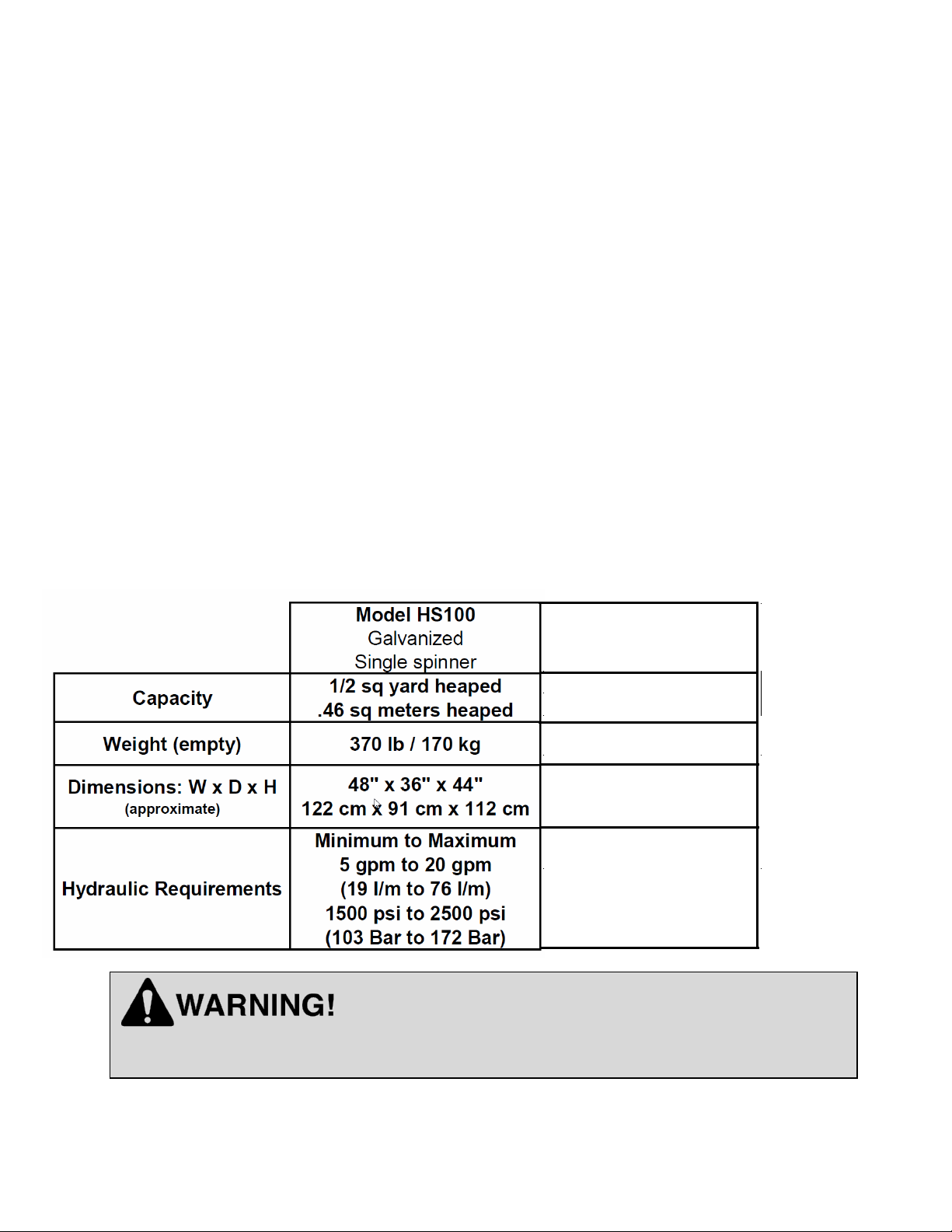

Depending upon the material used,the casting range of the HS100 is 3 ft. to 40 ft., (1 m

to 18 m) and the HS200 is 6 ft. to 60 ft., (2 m to 18 m) from the spreader. The limitations

or restrictions that govern the spreading radius may be dictated by either the material to

be dispersed and / or the surroundings. Keep a minimum of 75 ft (23 m) away from

bystanders while dispensing product.

Never let a child or an untrained person operate equipment.

DO NOT MODIFY THE BROADCAST SPREADER OR PRIME MOVER

Modifications may weaken the integrity of the Broadcast Spreader and may impair

the operation, safety, and performance of the product. When making repairs, only

qualified technicians using the manufacturer’s genuine parts, following authorized

instructions shall attempt the repair. Never modify any ROPS (Roll Over Protection

Structure) or FOPS (Falling Object Protective Structure) equipment or other safety

device or remove guarding. Any modifications must be sanctioned in writing by an

authorized representative of the manufacturer.

The following references are used throughout this Operator’s and Parts Manual:

Front or Rear

Mounted

Orientation that is determined in relation to the operator of the

equipment when seated in the normal operating position of the

prime mover

Prime Mover The engine-driven machine to which this product is attached

Right, Left, Front,

Rear

Orientation that is determined in relation to the operator of the

equipment when seated in the normal operating position. Unless

otherwise noted

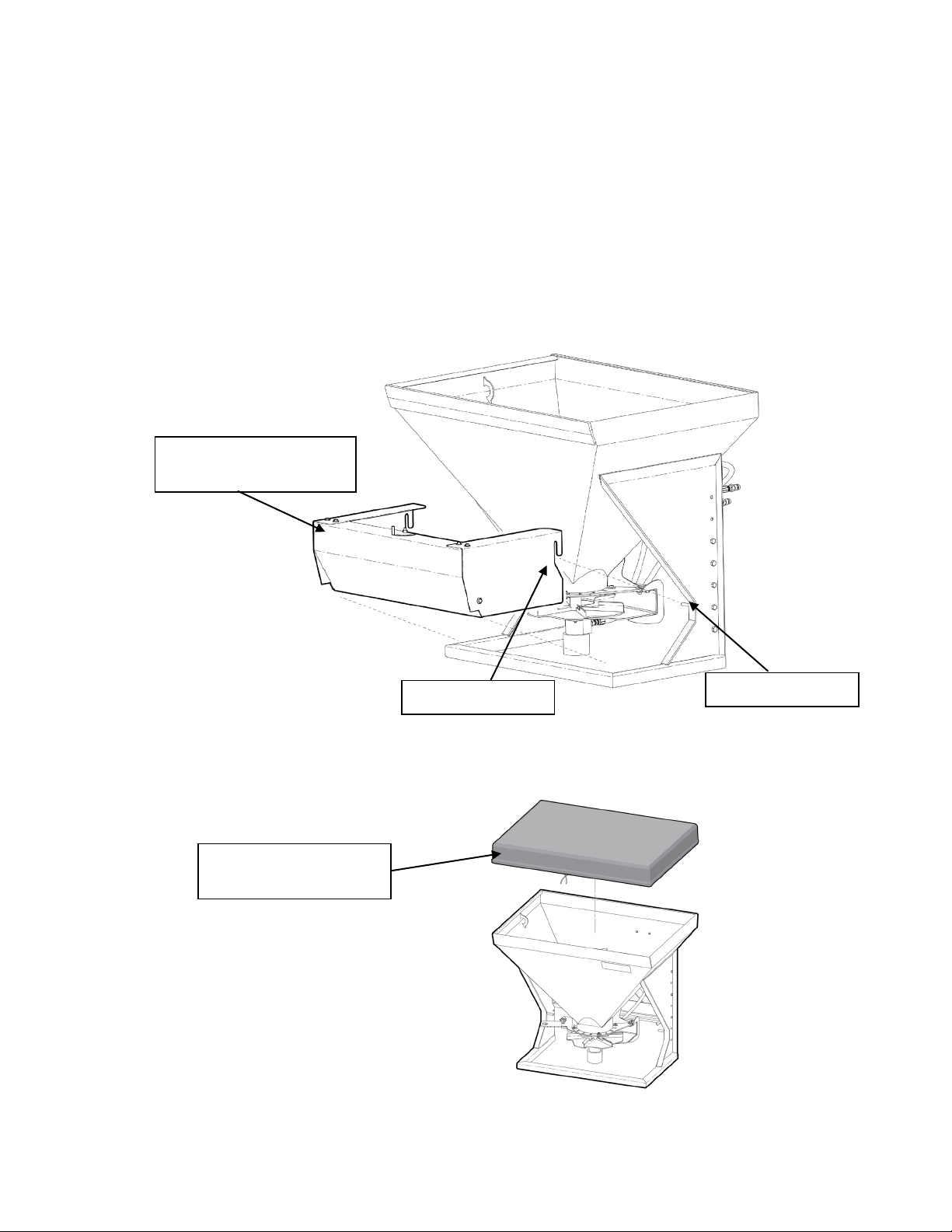

Attachment,

Implement

Refers to the Broadcast Spreader whether attached or separate

from the prime mover

Equipment Refers to the Implement and / or prime mover whether separate or

connected

WARNING,

CAUTION,

IMPORTANT

A notice that relates to the safe and efficient operation of the

Broadcast Spreader or prime mover. Read and understand the

reference before attaching or operating the Broadcast Spreader or

the prime mover

REFERANCES

Page 5