TABLE OF CONTENTS

INTRODUCTION ....................................... 2

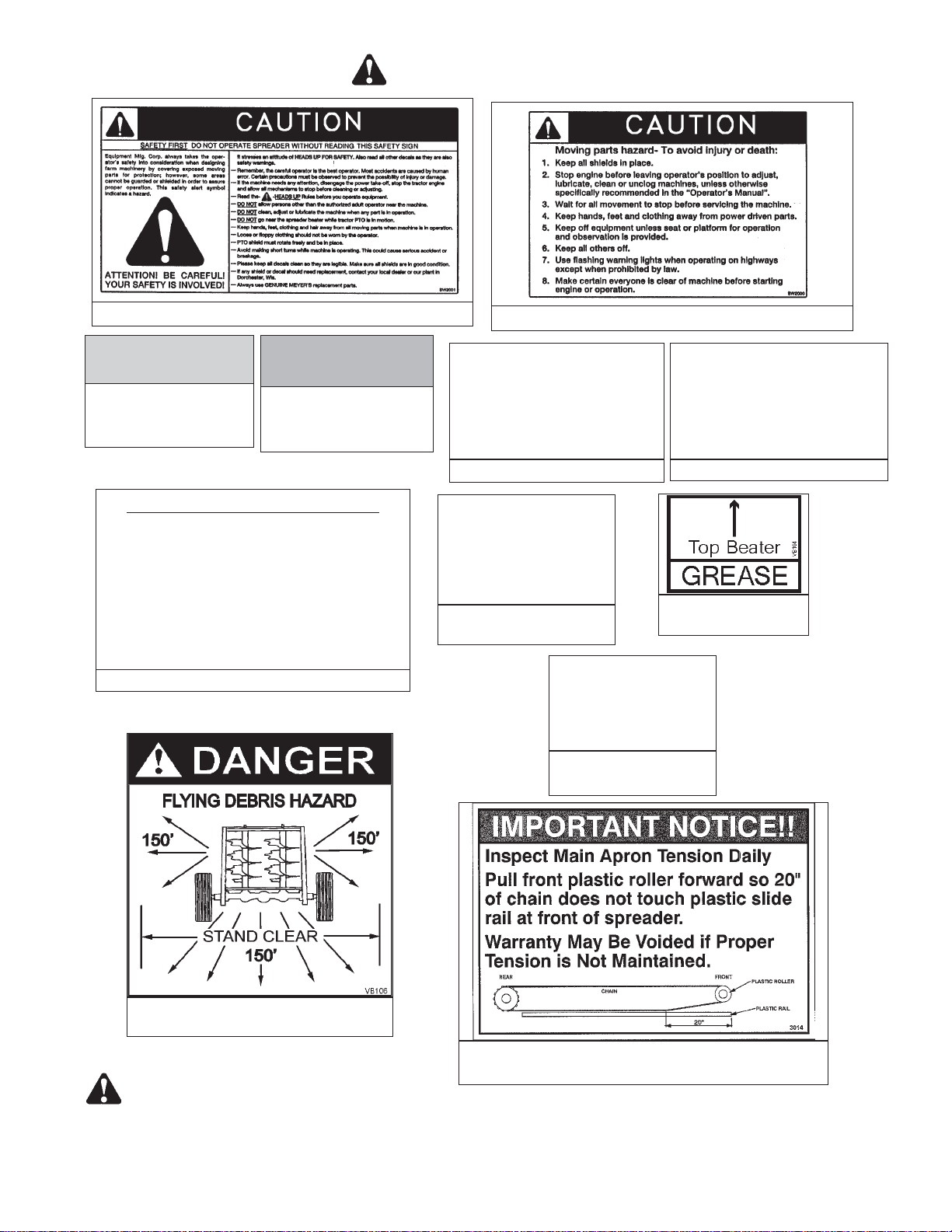

SAFETY............................................ 5

SAFETY SIGNS ....................................... 7

MANURE SPREADER SAFETY ...............................9

MANDATORY SAFETY SHUTDOWN PROCEDURE....................10

PRE-OPERATION...................................... 11

General ......................................... 11

Tractor Hitch And PTO Requirements ..........................11

ADMA Recommendations: ······························11

Tractor Size Requirements................................ 12

Tractor Towing Size Requirements··························12

Material Estimated Weight Per Cubic Foot······················12

Theory Of Operation ................................... 12

Hydraulic System .................................... 12

General········································ 12

Converting A Spreader From Closed Center To Open Center..............13

To Convert Standard Non Flow Controlled Closed Center System To Open

Center······································· 14

To Convert Optional On Board Flow Controlled Closed Center System To

Open Center ···································14

Electric Control Installation for Optional On Board Flow Controlled System .......15

Transporting ....................................... 16

General········································ 16

Use Safety Chain··································· 16

Use Lights ······································ 16

OPERATION ........................................ 17

Tractor Hookup ..................................... 17

Loading ......................................... 17

Unloading ........................................ 17

Mandatory Safety Shutdown Procedure .........................18

MAINTENANCE, ADJUSTMENTS & LUBRICATION ....................19

Wheel And Tire Maintenance And Repair ........................19

Lock Ring Rim ...................................... 19

Rear-Automatic Over Running Clutch ..........................19

Mandatory Safety Shutdown Procedure.........................19

Adjustments ....................................... 20

Apron Chain ····································· 20

Lubrication ........................................ 20

Cleaning And Storage ..................................22

REPAIR PARTS....................................... 24

Main Frame & Box Parts·································24

Hydraulic End Gate & Related Parts···························26

Jack Assembly······································ 28

Axles, Wheels, Spindles And Related Parts ·······················30

Page 3 MODEL: VB750