2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

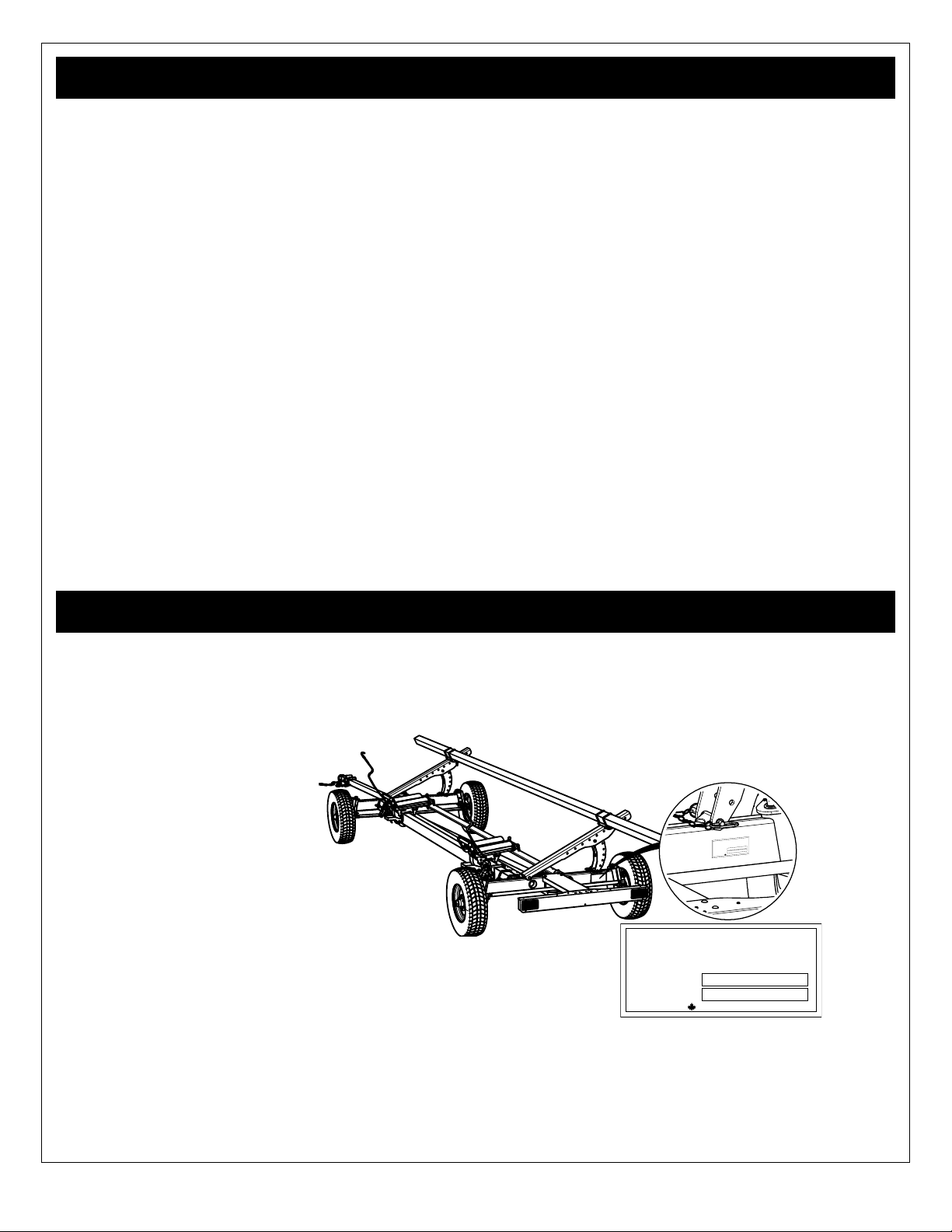

Serial Number Location . . . . . . . . . . . . . . . . . . .3

General Information . . . . . . . . . . . . . . . . . . . . . .4

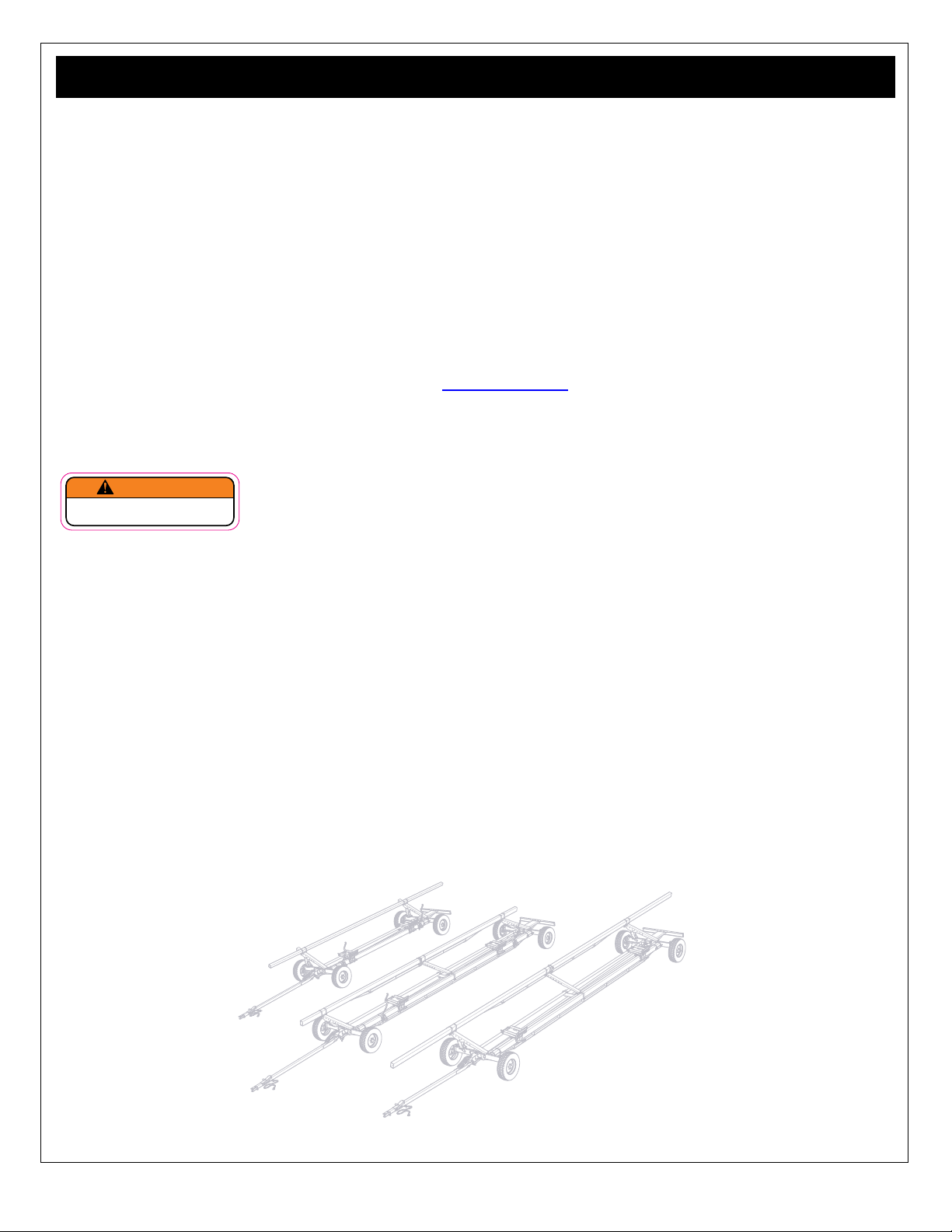

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

California Proposition 65 . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . .4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

. . . . . . . . .5

. . . . . . . . . . . . . . . . . . . . . . . . .6

Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . .7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Ratchet Strap Safety . . . . . . . . . . . . . . . . . . . . . . . .9

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . .9

. . . . . . . . . . . . . . . . . . . . . . . . . . .10

Brake Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Label Descriptions . . . . . . . . . . . . . . . . . . . 11

If labels need to be replaced:. . . . . . . . . . . . . . . . . 11

Safety Label Layout . . . . . . . . . . . . . . . . . . . . . . . .12

. . . . . . . . . . .13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Assembly & Inspection . . . . . . . . . . . . . . . . . .15

Components and Features . . . . . . . . . . . . . .15

CHCFE Series Wagon Components . . . . . . . . . . .15

Universal Header Pads . . . . . . . . . . . . . . . . . . . . .16

Quick Release and Lock . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . .17

. . . . . . . . . . . . . . . . . . . . . . . 17

Base Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Large Pad for Draper Head . . . . . . . . . . . . . . . . . . . . 17

High Back Pad for Flex Draper Head . . . . . . . . . . . . 18

Low Back pad for Standard Cutting Platform . . . . . . 18

Standard Corn Head with Low Back . . . . . . . . . . . . . 18

. . . . . . . . . . . . .19

Height Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Depth Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ratchet Strap System . . . . . . . . . . . . . . . . . . . . . .20

Release the strap from the ratchet: . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . .21

Safety Chain: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Spring Balancer:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Retractable Pullout w/ auto lock: . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . .22

. . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . 23

Header Wagon Capacity . . . . . . . . . . . . . . . . . . . .24

Four Wheel Steer. . . . . . . . . . . . . . . . . . . . . . . . . .24

Electric Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Brake Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . .25

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Universal Header Pads . . . . . . . . . . . . . . . . . . . . .26

:. . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . .27

. . . . . . . . . . . . . . . . . . . . . . . . . 27

Electric Brakes / Lights Setup . . . . . . . . . . . . . . . .28

. . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . 28

Synchronize the Brakes: . . . . . . . . . . . . . . . . . . . . . . 28

Field Operation . . . . . . . . . . . . . . . . . . . . . . . .29

Operation Safety Checklist . . . . . . . . . . . . . . . . . .29

Prepare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Loading the Header . . . . . . . . . . . . . . . . . . . . . . . .30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

. . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Storage Safety Checklist . . . . . . . . . . . . . . . . . . . .32

Placing the Implement in Storage:. . . . . . . . . . . . .32

Service & Maintenance . . . . . . . . . . . . . . . . . .33

Maintenance Safety Checklist . . . . . . . . . . . . . . . .33

Wheel Bearings:. . . . . . . . . . . . . . . . . . . . . . . . . . .33

Wagon Components: . . . . . . . . . . . . . . . . . . . . . . .34

. . . . . . . . . . . . . . . . . . . . . . . . . .35

. . . . . . . . . . . . . . . . . . . . . . . . .35

Electric Brake Maintenance . . . . . . . . . . . . . . . . . .36

Note: Initial Service: . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . .36

Wiring Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LED Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . .37

. . . . . . . . . . . . . . . . . .38

. . . . . . . . . . . . . . . . . . . . . . . .38

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . .39

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . .41

CHCFK Fender kit . . . . . . . . . . . . . . . . . . . . . . . . .41

. . . . . .41

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43