4

Safety

Always check the Cleanmeleon 800 Elektro for any damage or wear. Only a

flawless machine may be used.

When repairing and replacing, please only use original spare parts or parts approved

by the manufacturer.

The operator must be 18 years old and is responsible for people and animals that

may be in the work area.

The surface to be cleaned must first be cleaned of larger foreign objects. Also

stones, wires, pieces of wood, etc. Under certain circumstances, the machine can

move it in an uncontrolled manner.

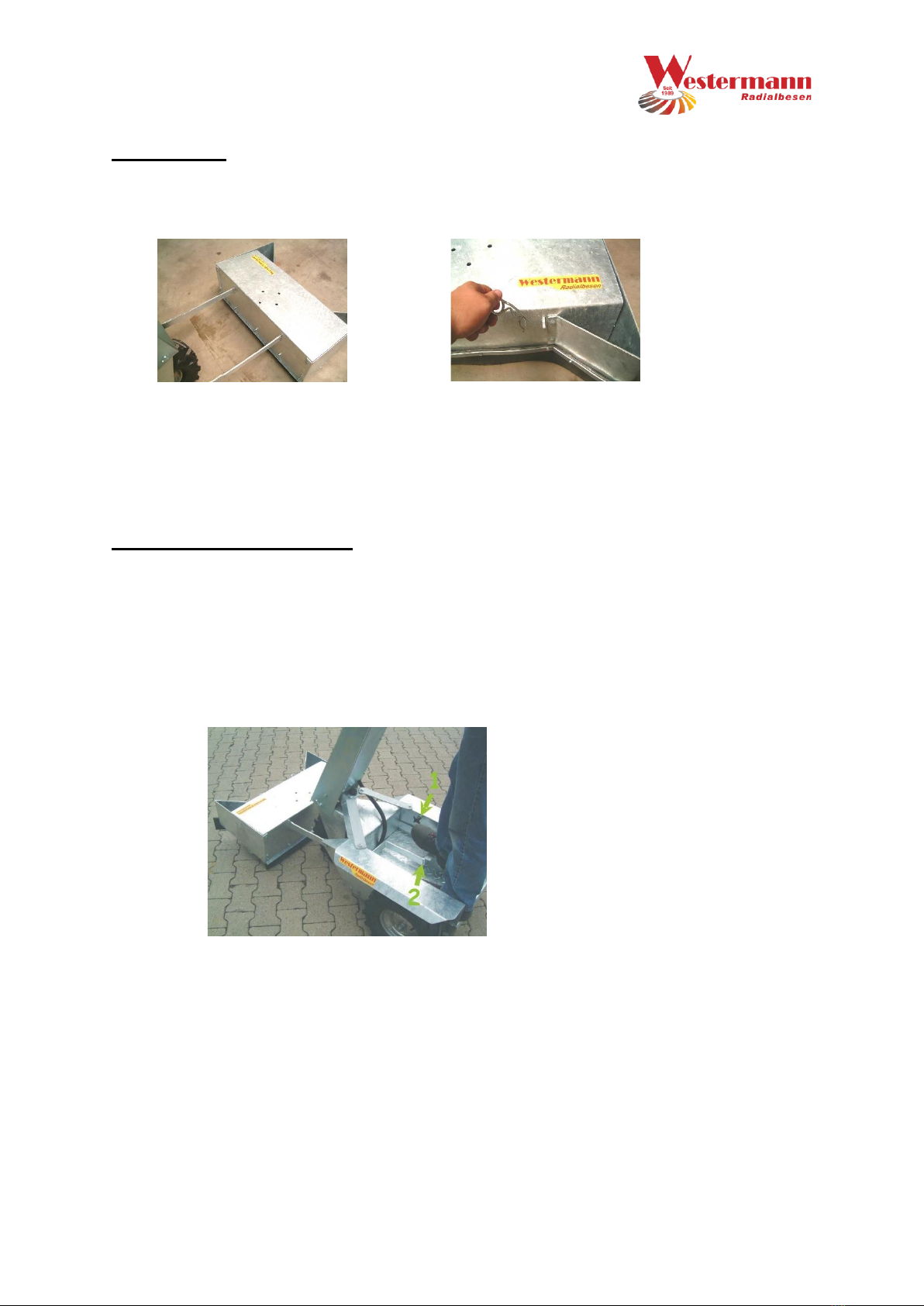

Please remove the child lock / plug lock after each use!

After each work process, the device must be connected to the supplied charger. This

prevents deep discharge of the batteries and the device is ready for use at any time.

Familiarize yourself with the handling of the device. Make a note of how to turn off

the device in an emergency.

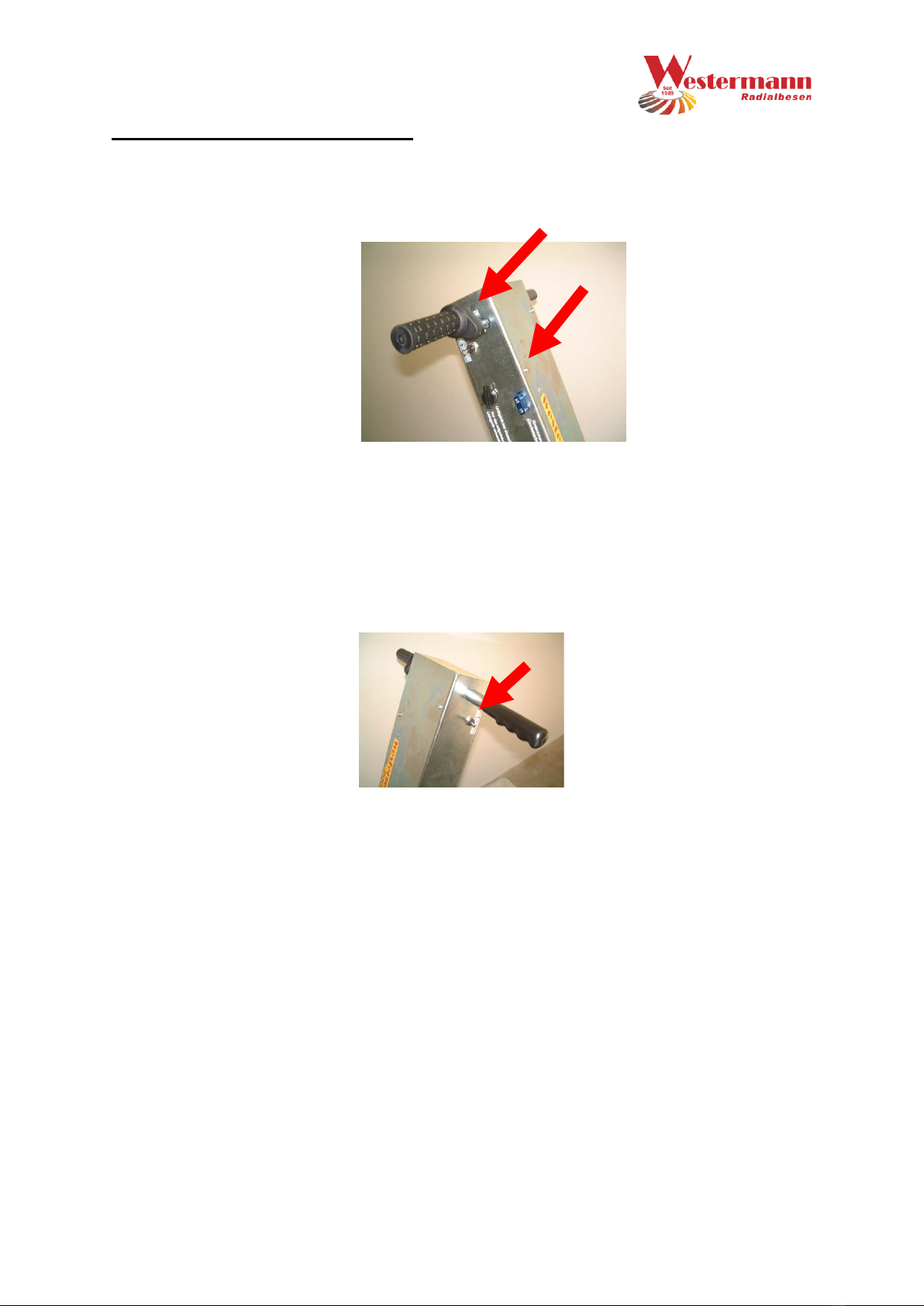

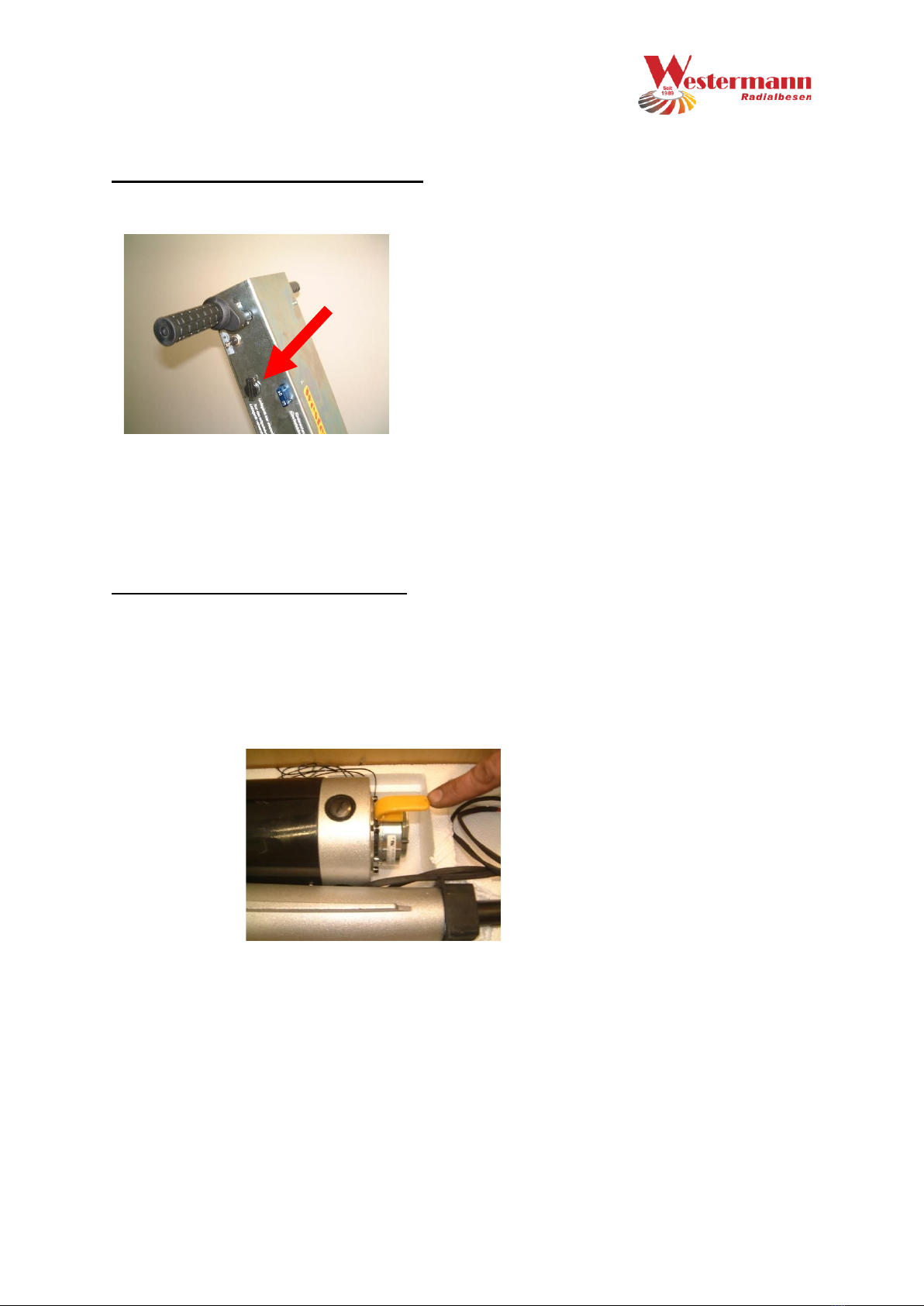

The fuse must be removed before the following work:

• Checking, cleaning or other work on the device

• Unusual noises or operating behavior

• With all settings of the device.

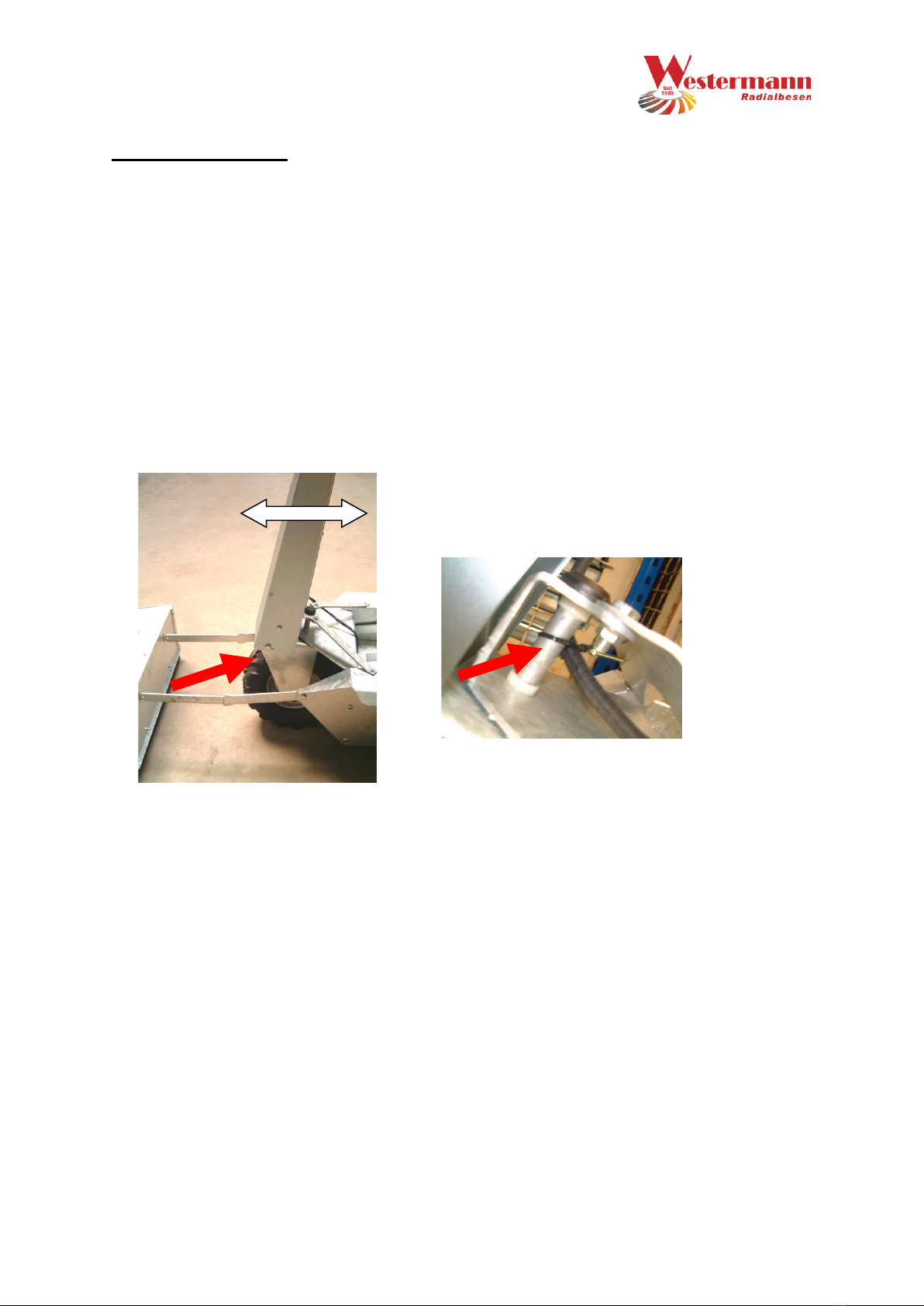

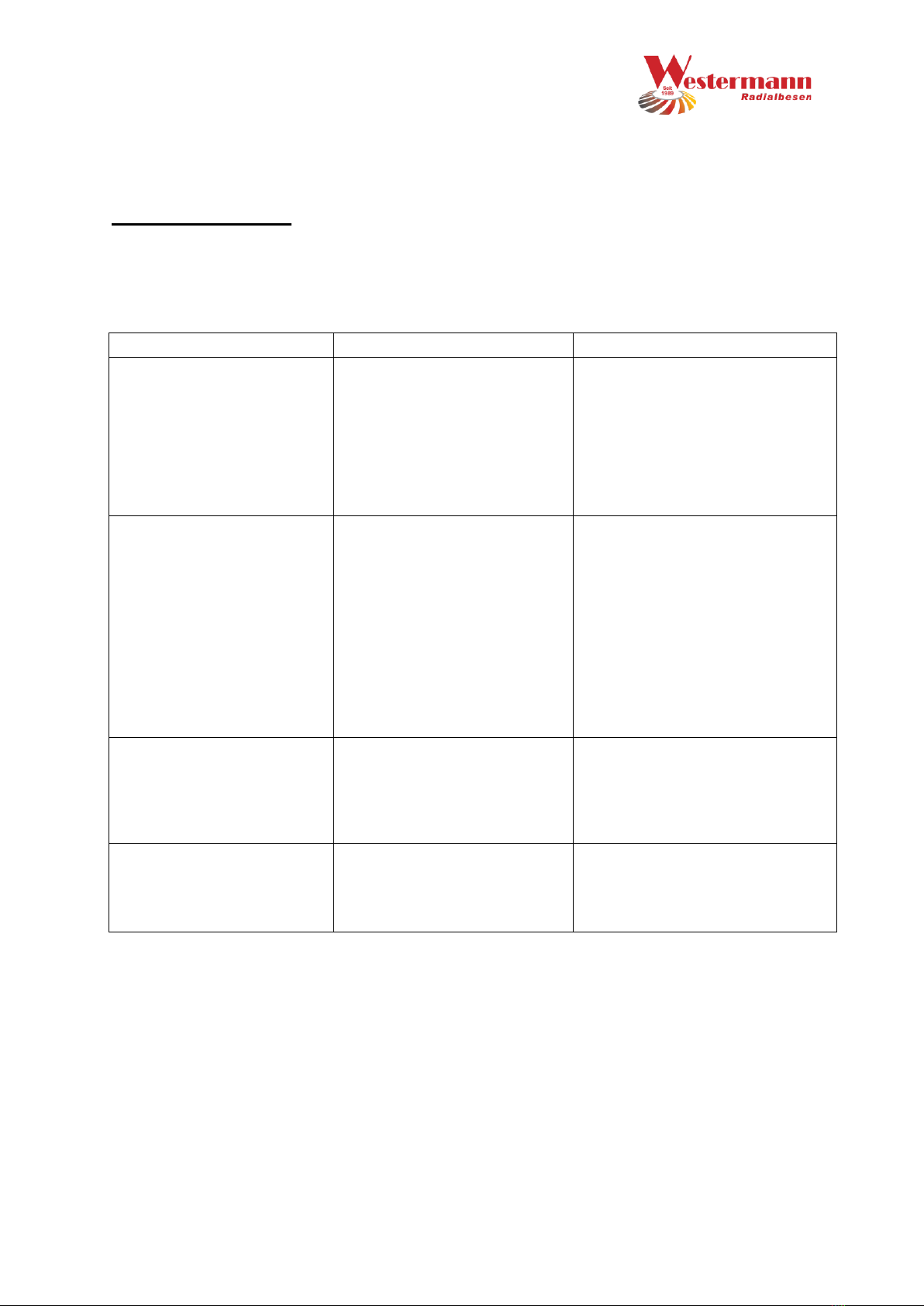

Only remove the add-on head (column slider) from the basic unit for cleaning. Do not

drive the device without this attachment head!

The Cleanmeleon 800 Elektro is used only for grooming in dairy farms and can

therefore only be used on flat surfaces!

Possible during use in the barn

Watch out for animal kicks!

Warranty guidelines for Westermann sweepers