Highline Manufacturing Bale Pro Feed Chopper 651 User manual

Operators Manual

E12363V2_A

Bale Pro®

Complete Feed Ration

Feed Chopper™ 651

Operator’s

Manual

Highline Manufacturing Limited

HWY #27, P.O. Box 307

Vonda, SK S0K 4N0

Canada

Phone: 306.258.2233

Fax: 306.258.2010

Toll Free: 1.800.665.2010

E12363V2_A

Feed Chopper

for the

BalePro®

Complete Feed Ration 651

Printed in Canada Copyright © 2018 by Highline Manufacturing Ltd. All rights reserved.

The content of this manual was based on the most current information available as of the date of copyright. It is the policy of

Highline Manufacturing Limited to improve and develop our products continually. We reserve the right to make changes or add

improvements, at any time, without incurring any obligation to make changes or improvements on machines previously sold.

Changes may not be reflected in this manual.

Highline Manufacturing Ltd. Feed Chopper on the CFR 651 (FC 651)

Highline Team Message

Congratulations on your purchase of the Feed Chopper for the Complete Feed Ration 651

(FC 651) manufactured by Highline Manufacturing Ltd.

This Operator's Manual has been prepared to provide information necessary for the safe and

efficient operation of your Feed Chopper. In the manual you will find safety procedures,

maintenance routines and detailed operational instructions.

If you find that you require information not covered in this manual, please feel free to consult

your local dealer. Your dealer is always able to contact Highline for this technical information.

HighlineManufacturingLtd. thanksandcongratulatesyoufor selecting a FeedChopperfor the

Complete Feed Ration 651 as your machine of choice.

Highline Manufacturing Ltd.

Table of Contents

General Description of the Feed Chopper

Intended Use of the Feed Chopper

Section 1 - Safety

SerialNumber ...........................................................................1

SafetySign-offForm ......................................................................2

SafetyAlertSymbol.......................................................................3

GeneralSafety ..........................................................................4

SafetyDecals ...........................................................................4

Section 2 - Feed Chopper Preparation

GeneralPreparation ......................................................................1

DoorSetupforChoppingOperation ..........................................................4

DoorSetupforBypassOperation ............................................................7

Section 3 - Operating the Feed Chopper

Chopping Operation - Operating With the Feed Chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Bypass Operation - Operating Without the Feed Chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

UnpluggingtheFeedChopper ..............................................................8

Section 4 - Maintaining the Feed Chopper

Lubrication..............................................................................1

Greasing the CFR 651 Rear Flail Drum Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TwineCutterAccess ......................................................................2

GreasingtheLowerFeederChainBearing.....................................................2

RotorKnifeReplacement ..................................................................2

RotorTwineScraperAdjustment.............................................................3

BeltTensionAdjustment ...................................................................4

Section 5 - Troubleshooting

This Page Left Blank

GENERAL DESCRIPTION OF THE FEED CHOPPER

The Feed Chopper (FC651) is an attachment to the Bale Pro

®

Complete Feed Ration 651.

When the Feed Chopper is engaged, it uses power from the flail drum of the CFR 651 to run

a belt drive for the Feed Chopper rotor.

Whenadditionalprocessingandchoppingof feedmaterialisdesired,theFeedChopperclutch

is engaged and the Feed Chopper door is moved to direct material from the CFR 651 into the

Feed Chopper. This further chops the material before discharging it. The CFR 651 must be

turned off when the Feed Chopper drive clutch is engaged and the discharge door is

positioned.

When the Feed Chopper clutch is not engaged and when the Feed Chopper door is in the

by-pass position, the CFR 651 discharges material without any additional chopping.

The operator of the CFR 651/Feed Chopper is located in the tractor cab to control the speed

of driving and the speed of operation of the CFR 651/Feed Chopper.

INTENDED USE OF THE FEED CHOPPER

The Feed Chopper is designed to further process and chop animal feed materials that have

been initially processed from a round bale by the CFR 651.

- The Feed Chopper is intended for use in farming applications.

- The Feed Chopper is intended for off road use only.

- The Feed Chopper is intended for use in locations away from people who could

be harmed by the discharged materials.

Any uses of the Feed Chopper other than the above stated Intended Uses shall be considered

misuse of the Feed Chopper. This misuse shall include (but not limited to):

- Using the Feed Chopper in non-farming applications

- Using the Feed Chopper on public roads

- Using the Feed Chopper around people or in public places

- Chopping materials other than animal feed materials

- Chopping materials that have not been initially processed by the CFR 651

AlwaysusetheFeedChopperaccordingtotheinstructionscontainedinthisOperator'sManual

and on the safety and instruction decals on the machine.

Perform regular maintenance and repair to ensure that the Feed Chopper operates safely and

efficiently.

This Page Left Blank

Section 1 - Safety

`SERIAL NUMBER

Your serialnumber is found on the serial number plate (1) attached to the right underside of the

Feed Chopper.

It is important to record the serial number for proof of ownership and for any service or

maintenance assistance.

Serial Number

Owner

Model

Date of Purchase

Serial Plate Location

215067C

Page 1-1

Section 1 - Safety

SAFETY SIGN-OFF FORM

Highline Manufacturing Ltd. follows the general Safety Standards specified by the American

SocietyofAgriculturalEngineers(ASAE)andtheOccupationalSafetyandHealthAdministration

(OSHA). Anyone who will be operating and/or maintaining the Feed Chopper 651 should read

and clearly understand all Safety, Operating and Maintenance information presented in this

manual.

Do not operate or allow someone to operate this equipment until this information has been

reviewed. This information should be reviewed by all operator’s before the season start-up.

This sign-off sheet is provided for record keeping to indicate that the person working with the

equipment has read and understood the information in the Operator’s Manual and has been

instructed in the safe operation of the equipment.

Date Employee’s Signature Employer’s Signature

Page 1-2

Section 1 - Safety

SAFETY ALERT SYMBOL

The Safety Alert Symbol means . . .

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert Symbol combined with a Signal Word alert tothe presence of a hazard and the

degree of possible injury.

Indicates an imminentlyhazardous situation that, if not

avoided, WILL result in DEATH OR SERIOUS INJURY.

The color is Red with White lettering.

Indicates a potentially hazardous situation that, if not

avoided, COULD result in DEATH OR SERIOUS

INJURY, and includes hazards that are exposed when

guards are removed or unsafe practices. The color is

Orange with Black lettering.

Indicates a potentially hazardous situation that, if not

avoided, MAY result in MINOR INJURY. The color is

Yellow with Black lettering.

Page 1-3

Section 1 - Safety

GENERAL SAFETY

1. Ensure that anyone who is going to operate, maintain or work near the Feed Chopper 651

isfamiliarwiththerecommendedoperating,maintenanceproceduresandsafetyinformation

contained in this manual and follows all the safety precautions.

2. In addition to the design and configuration of the equipment, hazard control and accident

prevention are dependant upon the awareness, concern, prudence and proper training of

personnel involved in the operation, transport, maintenance and storage of this equipment.

(Adapted from ASAE S474.1 Feb 04 - 5.2.5.1)

3. The Feed Chopper 651 shall not be operated without all the guards in place.

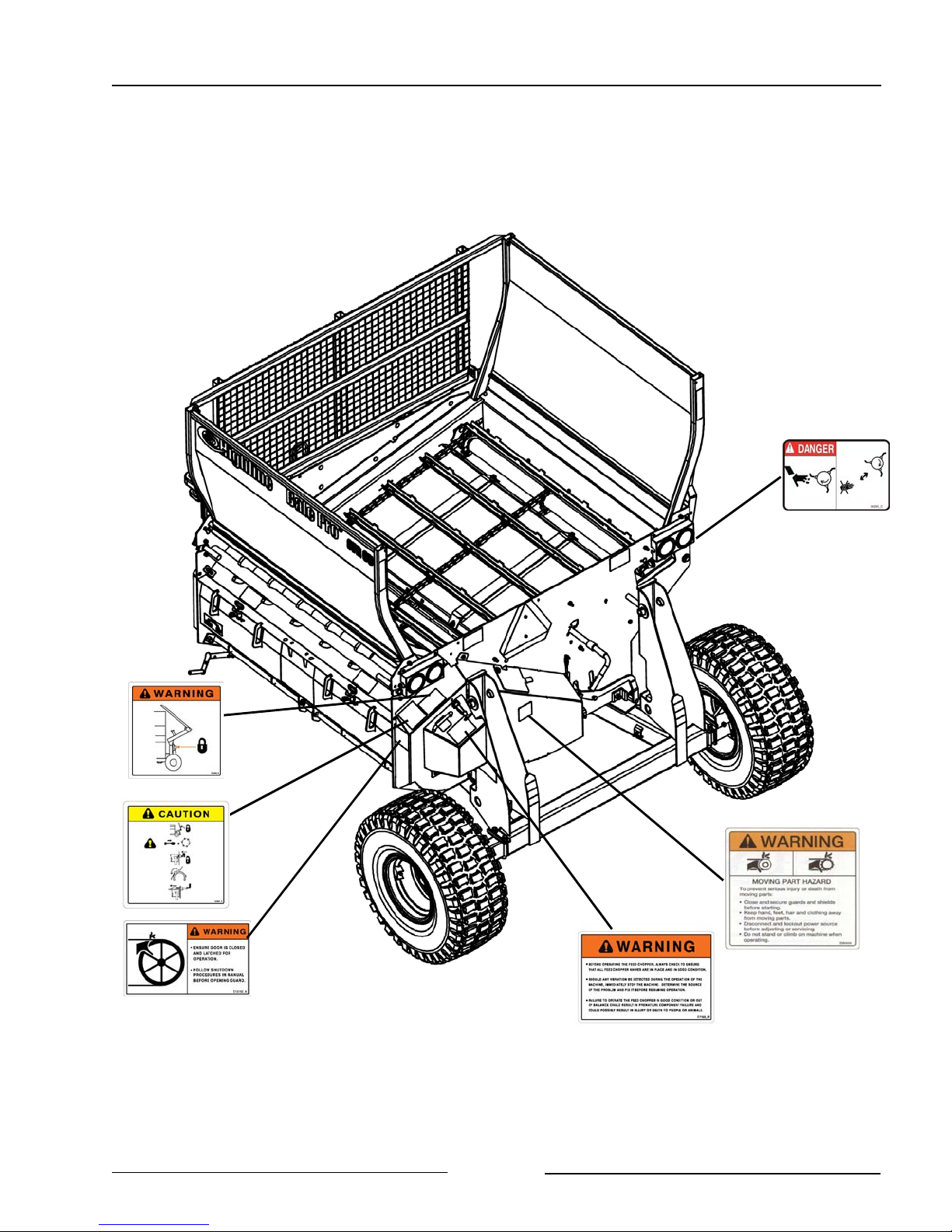

SAFETY DECALS

1. Keep the decals and signs clean and legible at all times.

2. Replace decals and signs that are damaged, missing or have become illegible.

3. Parts that have been replaced should display a current decal.

4. Decals are available from the Parts Department.

5. Be familiar with the decals, the type of warning and the area or function(s) related to the

area(s) that requires your awareness.

Page 1-4

Section 1 - Safety

DO NOT CONTACT THE ROTATING DRIVELINE

Contact with rotating driveline will cause serious injury or death.

Keep all driveline guards in place.

Securely attach drivelines at both ends.

Check that the driveline guards turn freely on driveline.

DO NOT CONTACT ROTATING BLADES

Rotating blades will cause serious injury or death.

Before servicing or adjusting, disengage power take off, shut of the

tractor, remove key, set park brake.

Before servicing or adjusting, wait for all parts to stop rotating.

Keep guards in place and in good condition.

KEEP PEOPLE AND ANIMALS CLEAR OF THE DISCHARGE

AREA

Discharge material exits at a high speed.

Discharged material will cause serious injury or death.

Stand clear of Feed Chopper when it is engaged.

SHUTDOWN THE TRACTOR BEFORE DISMOUNTING

TRACTOR

Shut down the tractor and remove the key before repairing,

servicing, lubricating or cleaning the Feed Chopper.

Page 1-5

Section 1 - Safety

DO NOT OPERATE WITH SHIELDS MISSING

Contact with the moving belt or sheaves may cause serious injury

or death.

Keep shields fastened in place.

Keep away from moving parts.

Do not stand or climb on the machine when operating.

READ, UNDERSTAND AND FOLLOW SAFETY INSTRUCTIONS

Read, understand and follow all instructions and safety messages

included in this manual and on decals attached to the machine.

These instructions and safety messages contain important

information.

Allow only responsible, properly instructed individuals to operate

and service the machine.

Failure to follow the instructions and safety messages in this

manual and on the decals attached to the machine could result in

serious injury or death.

Keep all safety and instruction decals in good condition. Replace

any missing or damaged decals.

CHECK CONDITION OF THE KNIVES BEFORE OPERATING

Check that all the knives are in place and in good condition.

If any vibration is detected during operation, immediately stop the

machine and determine the source of the vibration before

resuming.

Operating the Feed Chopper with knives missing or rotor out of

balance could result in injury or death.

Page 1-6

Section 1 - Safety

41807_B

SAFETY DECAL LOCATIONS

Page 1-7

Section 1 - Safety

This Page Left Blank

Page 1-8

Section 2 - Feed Chopper 651 Preparation

2.0 FEED CHOPPER 651 PREPARATION

General Preparation

1. Park the tractor and CFR 651 on level

ground.

- Engage the tractor parking brake.

2. Shut off the tractor engine and remove

the key.

3. Check the condition of the knives.

Disconnect thePTOdrivelinefrom

the tractor.

Do not place hands in the chopper

when it is rotating. Contact with

exposed rotating blades will cause

serious injury or death.

- Disengage the chopper clutch pin

from the flail drum drive plate. (See

Section 3 for procedures.)

- Spin the rotor by hand to check all the

knives.

- Check if they are broken or worn

to the point that they would not

process the material properly.

- For knife replacement information -

see Section 4 - “Maintaining the Feed

Chopper”.

Check Condition of the Knives

212075

Park On Level Ground

212075

Page 2-1

Section 2 - Feed Chopper 651 Preparation

4. Clear the rotor area of any material

buildup.

- Clear the chopping area and the

knives.

- Check the condition of the rotor and

the knife bolts.

- Remove twine or other materials that

may be wrapped around the ends of

the rotor shafts.

Clear Rotor Area of Buildup

212075

Remove Twine From Rotor Shaft

218162

Page 2-2

Section 2 - Feed Chopper 651 Preparation

5. Ensure the front drive shields are in good

repairandsecurelyclosedwiththerubber

latch.

The Feed Chopper shall not be

operated without all the driveline

shields in place and secured.

6. Ensure both reardriveshieldsareingood

repairandsecurelyclosedwiththerubber

latches.

Ensure Front Drive Shield Is Secured

213190

Ensure Rear Drive Shields Are Secured

217135

Page 2-3

Section 2 - Feed Chopper 651 Preparation

Door Setup For Chopping Operation

There are 2 doors to adjust for Chopping

operation. These doors must be set to direct

material into the Feed Chopper rotor.

Note:The Feed Chopper drive clutch

must be disengaged and all

rotation of the chopper rotor

stoppedbeforemovingthechopper

door.

Serious damage to the Feed

Chopper knives and Chopper door

will result if the drive clutch is

engaged with the Chopper door in

the Bypass position. The rotating

knives will hit the door.

#1 - Adjust the Feed Chopper Door

1. Disconnect the front and rear hangers

from the Chopper door handles.

- Remove the clip pin and disconnect

the hanger from the door handles.

2. Connect Handle At the Front Tub

Wall:

- Move the handle down until it rests in

the bottom of the outer slot (3).

- Continue to move the handle down

until the inner bolt (4) is near the

middle of the inner slot.

- Place the handle pin into the C1

position (2) on the door hanger.

- Fasten in place with the clip pin.

Connect the Front Handle to “C1” Position

213203C

Page 2-4

Section 2 - Feed Chopper 651 Preparation

3. Connect Handle At the Rear Tub Wall:

- Move the handle down until it rests in

the bottom of the outer slot (3).

- Continue to move the handle down

until the inner bolt (4) is near the

middle of the inner slot.

- Place the handle pin into the C1

position (2) on the door hanger (1).

- Fasten in place with the clip pin.

4. Visually check that the back of the

chopper door is fully raised against the

tub wall.

Connect the Rear Handle To “C1" Position

213215C

Check That Door Is Fully Raised

212075

Page 2-5

Table of contents

Other Highline Manufacturing Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions