Form 169078 Revision C

TABLE OF CONTENTS

INTRODUCTION........................................................................................................................................................ 2

GENERAL SAFETY .................................................................................................................................................. 4

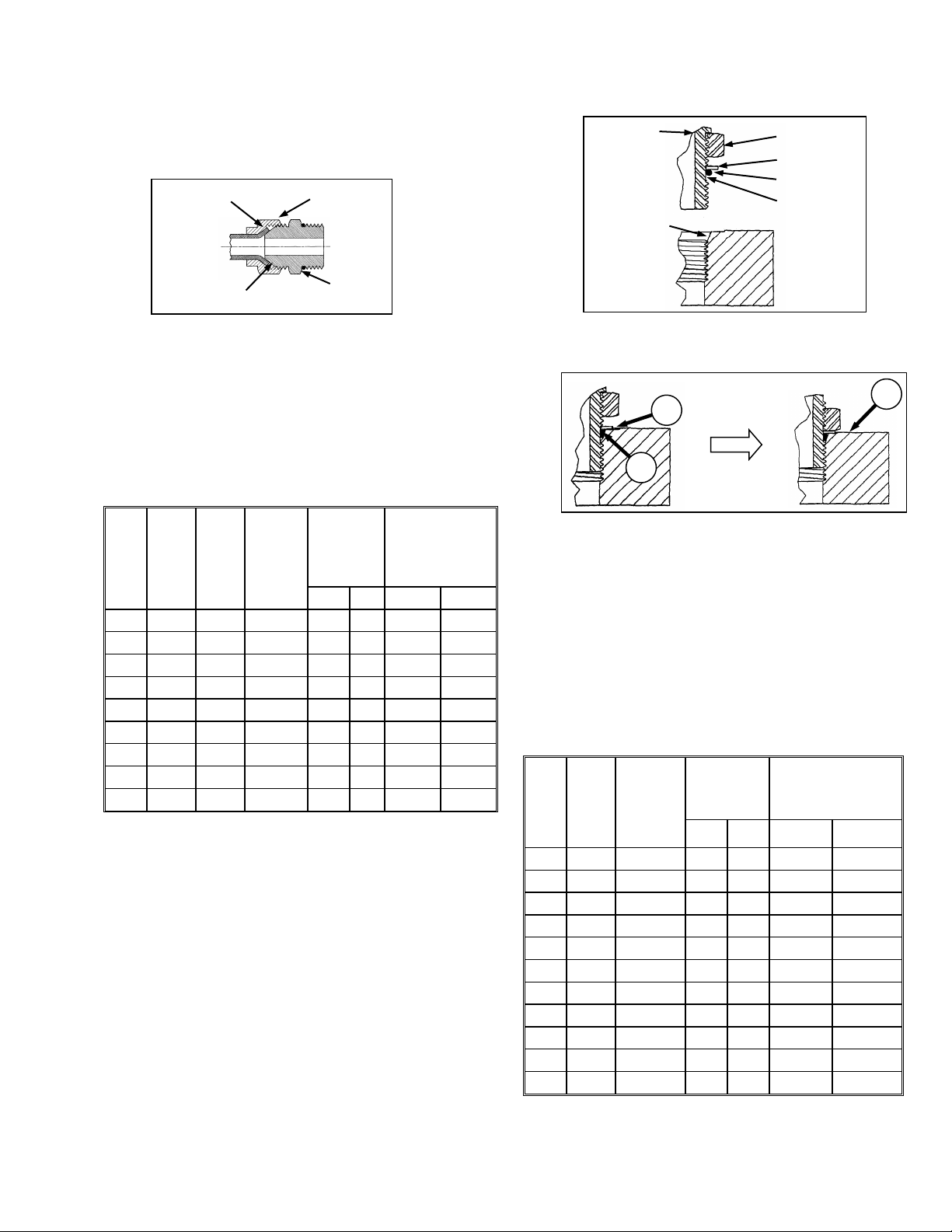

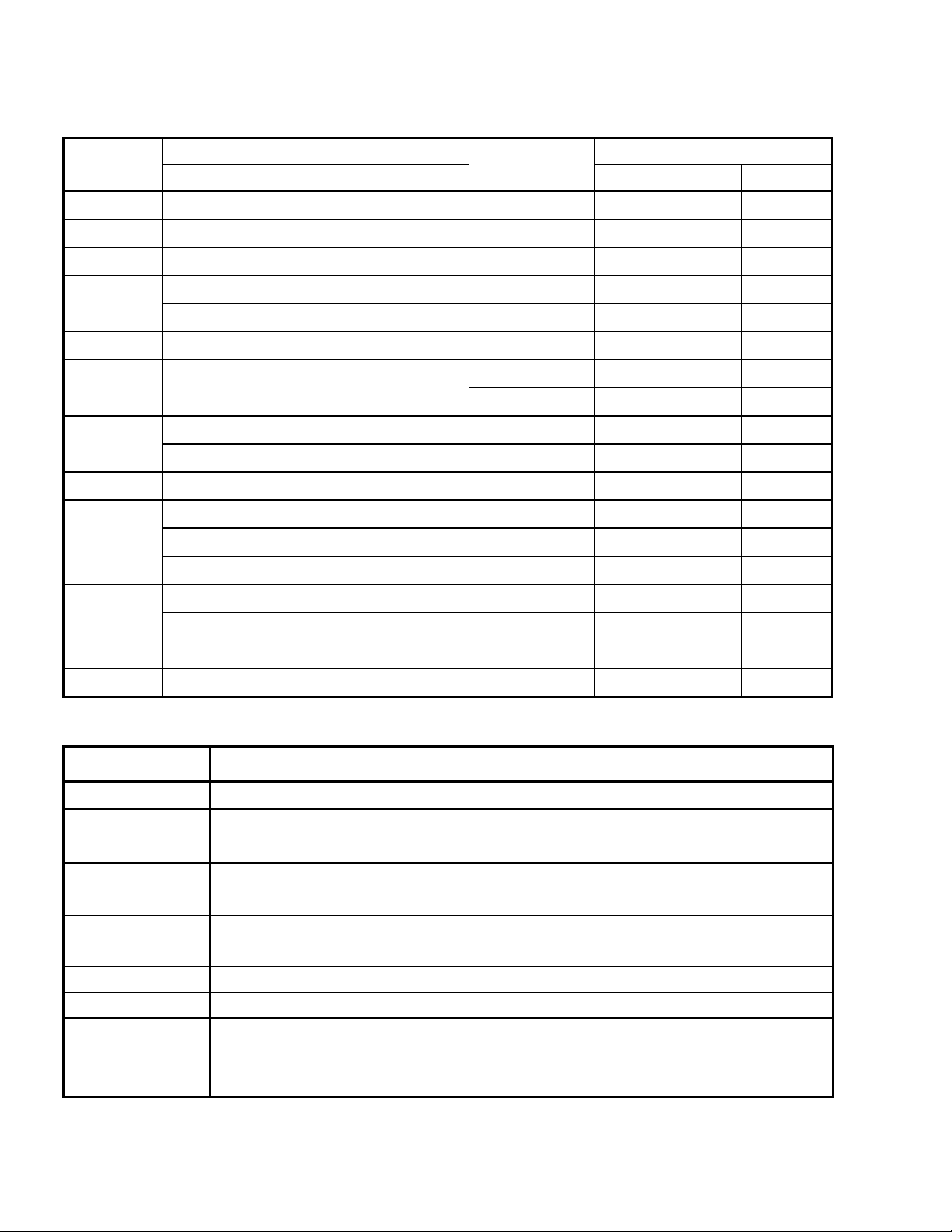

RECOMMENDED TORQUES ................................................................................................................................... 6

A. GENERAL..................................................................................................................................... 6

B. SAE BOLTS .................................................................................................................................. 6

C. METRIC BOLTS ........................................................................................................................... 6

D. HYDRAULIC FITTINGS................................................................................................................ 7

ENGLISH/METRIC EQUIVALENTS.......................................................................................................................... 8

DEFINITIONS ............................................................................................................................................................ 8

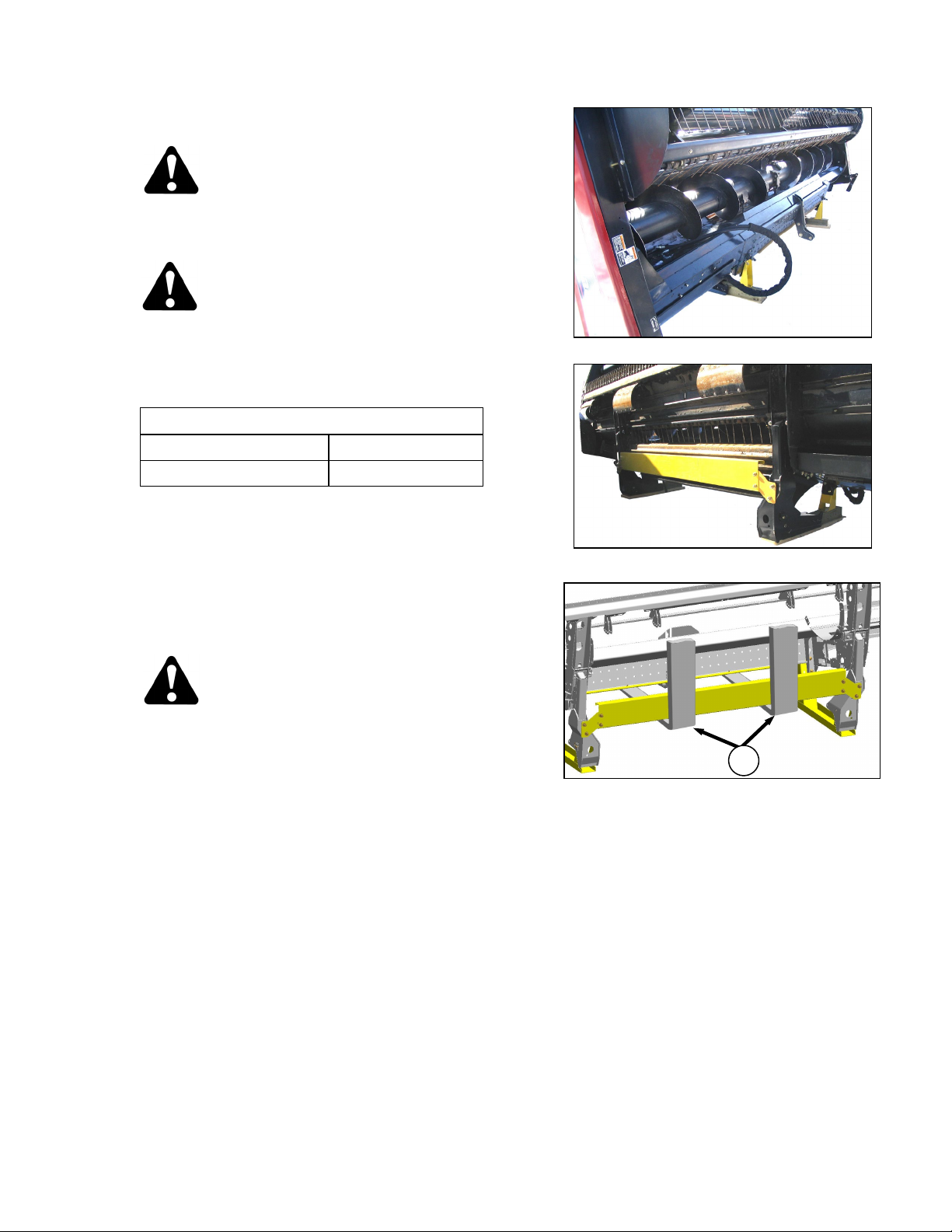

STEP 1. UNLOAD HEADER............................................................................................................................. 9

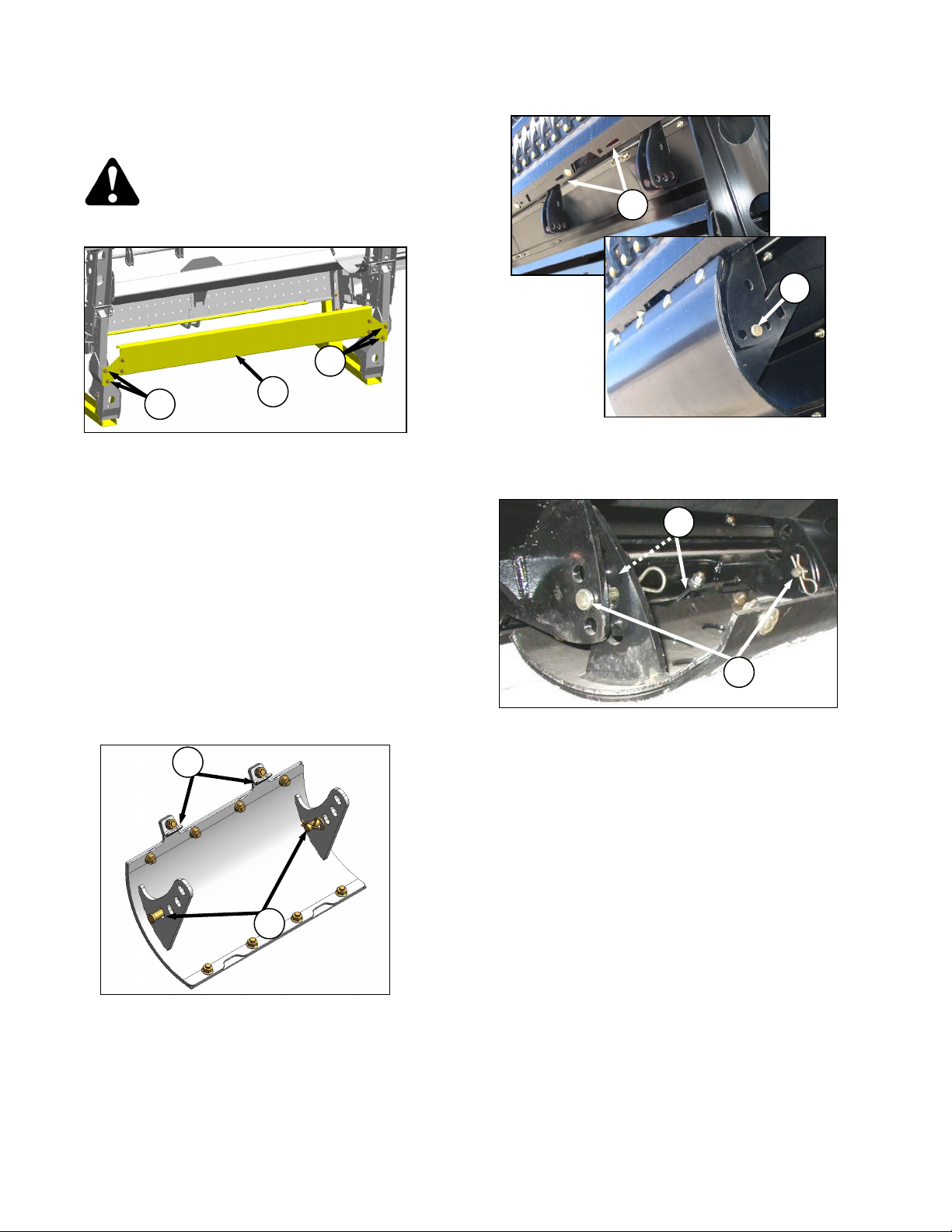

STEP 2. REMOVE UNDERSIDE SHIPPING STAND..................................................................................... 10

STEP 3. INSTALL ADDITIONAL SKID SHOES............................................................................................. 10

STEP 4. INSTALL GAUGE ROLLERS........................................................................................................... 11

STEP 5. LOWER HEADER............................................................................................................................. 12

STEP 6. REMOVE SHIPPING STANDS......................................................................................................... 13

STEP 7. INSTALL TALL CROP DIVIDER ...................................................................................................... 14

STEP 8. ADJUST LEAN BAR ........................................................................................................................ 15

STEP 9. ADJUST PAN EXTENSIONS - GRASS SEED SPECIAL ............................................................... 15

STEP 10. ADJUST LIGHTS.............................................................................................................................. 15

STEP 11. ASSEMBLE FORMING SHIELD ...................................................................................................... 16

STEP 12. INSTALL FORMING SHIELD........................................................................................................... 17

STEP 13. ATTACH HEADER TO WINDROWER............................................................................................. 18

STEP 14. MODIFY HYDRAULICS.................................................................................................................... 21

A. A30-S AND A30-D ...................................................................................................................... 21

B. A40-D.......................................................................................................................................... 21

I. M100 ...................................................................................................................................... 21

II. M150 ...................................................................................................................................... 23

III. M200 ...................................................................................................................................... 24

IV. M205 ...................................................................................................................................... 26

STEP 15. CONFIGURE REVERSER VALVE JUMPER HOSE ....................................................................... 27

STEP 16. ATTACH HYDRAULICS ................................................................................................................... 29

A. A30-S, A30-D.............................................................................................................................. 29

I. M100, M150, M200, M205 ..................................................................................................... 29

B. A40-D.......................................................................................................................................... 31

I. M100 ...................................................................................................................................... 33

II. M150 ...................................................................................................................................... 33

III. M200 ...................................................................................................................................... 33

IV. M205 ...................................................................................................................................... 33

STEP 17. CONFIGURE HOSE ROUTING........................................................................................................ 34

STEP 18. REPOSITION WOBBLE BOX BREATHER ..................................................................................... 34

STEP 19. LUBRICATE THE HEADER ............................................................................................................. 35

STEP 20. PERFORM PRE-DELIVERY CHECKS ............................................................................................ 44

A. DRIVE BELTS AND DRIVE CHAINS ......................................................................................... 44

I. A30-S SINGLE KNIFE ........................................................................................................... 44

II. A30-D DOUBLE KNIFE ......................................................................................................... 44

III. A40-D DOUBLE KNIFE ......................................................................................................... 45

B. AUGER STRIPPER BAR CLEARANCE .................................................................................... 46

C. REEL TINE TO HEADER PAN CLEARANCE............................................................................ 46

D. HEADER FLOTATION................................................................................................................ 47

E. HEADER LEVELLING ................................................................................................................ 48

F. CONDITIONER ROLLS.............................................................................................................. 49

G. SKID SHOES/GAUGE ROLLERS .............................................................................................. 50

H. LIGHTS ....................................................................................................................................... 50

I. RUN-UP THE HEADER.............................................................................................................. 51

J. KNIFE ......................................................................................................................................... 52

K. MANUALS................................................................................................................................... 52