ZZOONNEEPPLLUUSSFF222288mm//FF222288ee

IINNSSTTAALLLLAATTIIOONNAANNDD

CCOOMMMMIISSSSIIOONNIINNGGIINNSSTTRRUUCCTTIIOONNSS

LEAFLET No P82412

ISSUE 1

PPaaggee44

Website: www.horstmann.co.uk

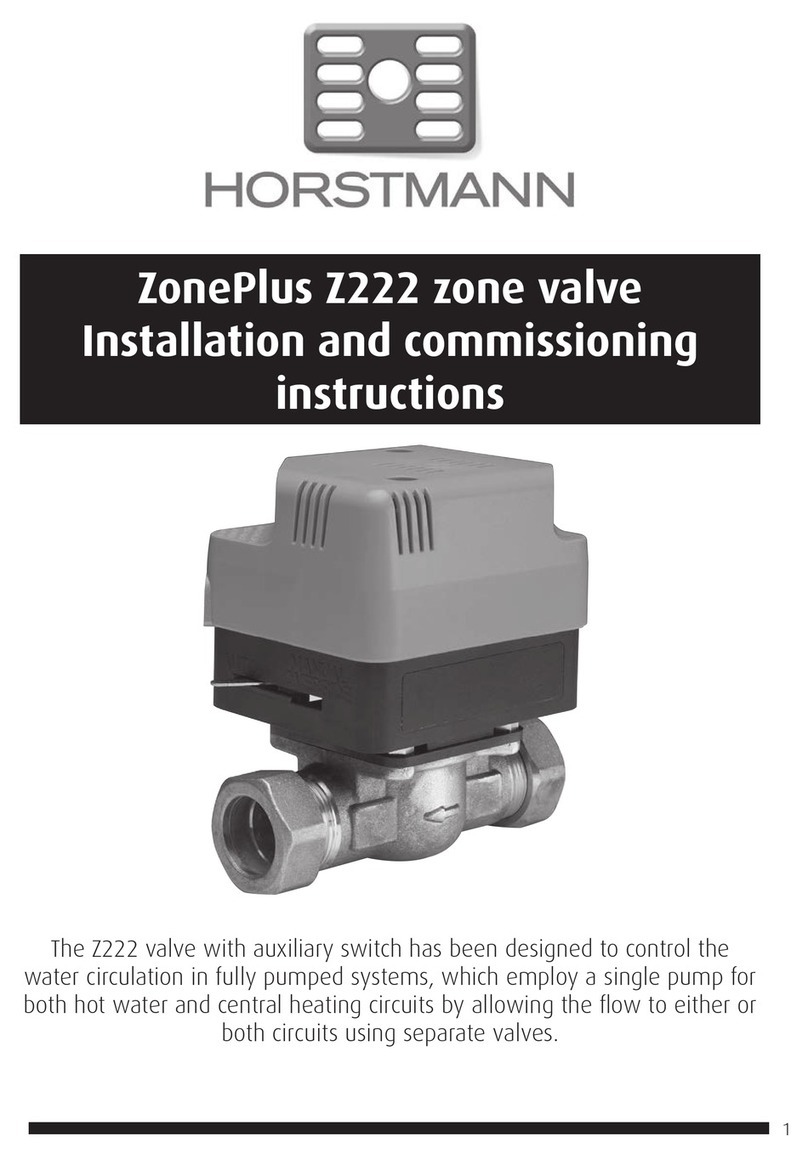

The F228m / F228e valve with auxiliary switch has been designed

to control the water circulation in fully pumped systems, which

employs a single pump for both Hot water and Central heating

circuits, by allowing the flow to either or both circuits using

separate valves.

Horstmann Controls Limited

Bristol

BS4 1UP

t:0117 9788 773 - f:0117 9788 701

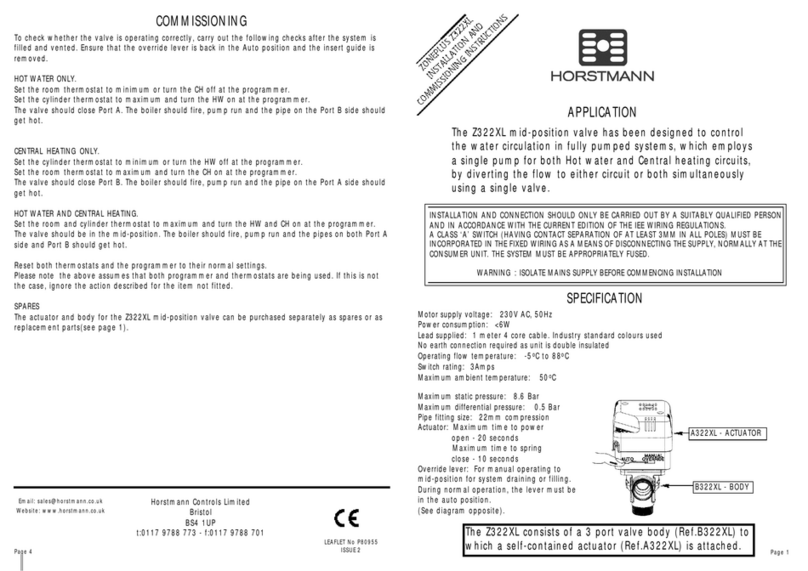

MMoottoorrssuuppppllyyvvoollttaaggee::230V AC, 50Hz

PPoowweerrccoonnssuummppttiioonn::<6.5W

LLeeaaddssuupppplliieedd::1 metre 6 core cable. Industry standard colours used

EEaarrtthhccoonnnneeccttiioonnrreeqquuiirreedd..

OOlliivveeSSiizzee::F228m - 28mm (Metric)

F228e- 1 1/4 inch (Imperial)

OOppeerraattiinnggfflloowwtteemmppeerraattuurree::Up to 80oC

SSwwiittcchhrraattiinngg::5 Amps

MMaaxxiimmuummaammbbiieenntttteemmppeerraattuurree::50oC

MMaaxxiimmuummssttaattiiccpprreessssuurree::21 Bar

MMaaxxiimmuummddiiffffeerreennttiiaallpprreessssuurree::2 Bar

PPiippeeffiittttiinnggssiizzee::22mm compression

AAccttuuaattoorr::Maximum time to power open - 20 seconds

Maximum time to spring close - 10 seconds

OOvveerrrriiddeelleevveerr::For manual operating to open valve for system draining or filling.

During normal operation, the lever must be in the auto position.

SPECIFICATION

PPaaggee11

INSTALLATION AND CONNECTION SHOULD ONLY BE CARRIED OUT BY A SUITABLY QUALIFIED

PERSON AND IN ACCORDANCE WITH THE CURRENT EDITION OF THE I.E.E. WIRING

REGULATIONS. A CLASS ‘A’ SWITCH (HAVING CONTACT SEPARATION OF AT LEAST 3MM IN

ALL POLES) MUST BE INCORPORATED IN THE FIXED WIRING AS A MEANS OF DISCONNECTING

THE SUPPLY, NORMALLY AT THE CONSUMER UNIT. THE SYSTEM MUST BE APPROPRIATELY

FUSED.

WWAARRNNIINNGG::IISSOOLLAATTEEMMAAIINNSSSSUUPPPPLLYYBBEEFFOORREECCOOMMMMEENNCCIINNGGIINNSSTTAALLLLAATTIIOONN

COMMISSIONING

To check whether the valve is operating correctly, carry out the following checks after the sys-

tem is filled and vented. Ensure that the override lever is in the Auto position and the insert

guide is removed.

FFOORRGGRRAAVVIITTYYSSYYSSTTEEMMSS::

HHOOTTWWAATTEERROONNLLYY..

Set the room thermostat to minimum or turn the CH off at the programmer.

Set the cylinder thermostat to maximum and turn the HW on at the programmer.

The valve should be open and the boiler only should fire.

CCEENNTTRRAALLHHEEAATTIINNGGOONNLLYY..

Set the cylinder thermostat to minimum or turn the HW off at the programmer.

Set the room thermostat to maximum and turn the CH on at the programmer.

The valve should remain closed but the boiler should fire and the pump should run.

HHOOTTWWAATTEERRAANNDDCCEENNTTRRAALLHHEEAATTIINNGG..

Set the room and cylinder thermostat to maximum and turn the HW and CH on at the

programmer.

The valve should be open. The boiler should fire, pump run and the pipes on the Port B should

get hot.

FFOORRAAFFUULLLLYYPPUUMMPPEEDDSSYYSSTTEEMM::

IIfftthheevvaallvveeiissffiitttteeddoonnaaHHWWcciirrccuuiitt..

Set the cylinder thermostat to maximum or turn the HW on at the programmer. The valve

should open. The boiler should fire, the pump run and the pipe on the Port B side should get

hot.

IIfftthheevvaallvveeiissffiitttteeddoonnaaCCHHcciirrccuuiitt..

Set the room thermostat to maximum or turn the CH on at the programmer. The valve should

open. The boiler should fire, the pump run and the pipe on the Port B side should get hot.

Reset both thermostats and the programmer to their normal settings.

PPlleeaasseennootteethe above assumes that both programmer and thermostats are being used. If this

is not the case, ignore the action described for the item not fitted.