When using the lock - use distance sleeves in the side

hinge between the first and second panel.

In gates equipped with lock or bolt it is recommended

to install a lock or bolt sensor.

Removing the keys connecting the shaft with the

servomotor and disassembling the servomotor is only

possible with the gate fully closed.

It is not allowed to operate the gate if there is visible

damage to the drive lines.

8.1. Running maintenance instructions:

8.2. Operations that can be performed by the authorized, trained

personnel having proper qualifications:

8.3. Operations that can be performed exclusively by authorized

service FPHU WIŒNIOWSKI:

Do not block the area of the gate leaf movement.

21. Adjust initially the roller of the first section (fig. 50).

22. Adjust initially the roller of other sections (fig. 50.1).

23. Gate lifting/lowering test (fig. 51).

24. Check correct operation of the electrical protection devices (if used):

photocells - by simulating the operating conditions - after cutting

the light flux the gate should stop and move back,

optical strip - the gate should stop and move back, when the leaf

touches 40 [mm] high object, placed on the floor. If necessary,

adjust and check again, since bad adjustment can result in accident,

lock sensor - when the lock is in locked position the gate should not

start,

pass door sensor - when the door is open the gate should not start.

There is a risk that during installation of the gate some errors can be made,

which can be easily avoided by paying attention that:

vertical guides are properly installed, according to the specification

provided in these instructions,

the closed gate leaf creates equal plane, sections must not show any

deformations - any displacements of the sections should be corrected

on the hinges,

side hinges are adjusted according to the instructions,

end stop are pressed when the gate is open (fig. 26),

all fasteners must be properly tightened.

Failure to follow the above mentioned basic guidelines may cause

problems in correct functioning of the gate, damage to the gate or in

consequence can void the guarantee.

Disassemble the gate in the reverse order as when assembling it.

General proper maintenance conditions for the gate, assuring its long,

trouble-free service:

should you find any malfunctioning of the gate stop using the gate and

contact the authorized service,

do not block the area of the gate leaf movement. When opening and

closing the door leaf make sure that there are no people, especially

children or objects in its way,

do not pass, run or drive under the moving gate, avoid excessive

contamination of the gate leaf, particularly protect the leaf from

harmful elements which could scratch the surface e.g. with sand,

the floor around the bottom washer should ensure free water draining,

protect the gate from contact with any substances harmful to varnish

coatings and metals, ex. caustic substances (acid, lye, salt),

when finishing the room or when renovating it protect the gate from

contact with plaster chips, paints and solvents,

the gate operated electrically should be opened following the

instructions supplied with the electrical equipment,

if during lifting of the gate some excessive resistance is encountered

check correct adjustment of the hinges, if necessary, adjust the hinges

according to the installation instructions,

if pass door are installed in the gate do not lift the gate if the door is not

locked,

after installation (at the latest up to two weeks) remove the protective

foil from the panel surface,

starting the gate when the gate is locked is not allowed.

Operations that can be performed by the client after getting thoroughly

acquainted with the Operating and Maintenance Instructions supplied

with the gate:

for cleaning the gate sections use mild cleansers, safe for varnish

coatings ex. water and soft sponge or cleaning agents intended for use

with varnish coatings available on the market,

for cleaning glazed sections do not use agents containing alcohol or

solvents (may cause dulling of acrylic glass), you can use mild cleaning

agents but we recommend to do some testing first on small glazing

surface,

minimum once per three months and in the case of industrial gates

once a month perform by your own running inspections of the gate to

check the following:

check if the cables are not loose or damaged (broken wires,

corrosion),

check tightening and correct mounting of all fasteners, particularly

screws securing guides, screws securing hinges,

in case of any faults they must be completely removed,

it is not allowed to operate the gate if there is visible damage to the

drive lines,

lubricate the running rollers and hinges at least once every six months

using white mineral oil,

replace the supply batteries at least once every 12 months,

for electrically driven gates check correct adjustment of the limit

switches (check by pressing the corresponding up/down button on the

control panel, observing where the gate stops) - after the gate stops in

closed position the cables should remain stretched, after the gate stops

in open position the bottom gasket should not protrude above the gate

opening,

for electrically driven gates once every month check correct operation

of electrical safety devices (if used):

photocells - by simulating the operating conditions - after cutting

the light flux the gate should stop and move back,

optical strip - the gate should stop and move back, when the leaf

touches 40 [mm] high object, placed on the floor. If necessary,

adjust and check again, since bad adjustment can result in accident,

lock sensor - when the lock is in locked position the gate should not

start,

pass door sensor - when the door is open the gate should not start,

check operation of the emergency opening facility supplied with the

servomotor.

minimum once per six months and in the case of industrial gates once

per three months perform inspections of the gate to check the

following:

check cables on the entire length, for damage (broken wires,

corrosion), check cable fitting on cable drums,

check tightening and correct mounting of all fasteners, particularly

screws securing guides, screws securing hinges, and keys, fastening

of the servomotor,

check proper functionality of devices protecting from cable

breaking,

in the case of errors in work of electrical drives disconnect the drive

from power supply for 2, 3 min and reconnect,

check adjustment of the rollers, adjust if necessary,

check condition of pass doors - adjust if necessary,

any modifications of the gates,

replacement of the protection from cable breaking,

replacement of cables, cable drums,

repairs of electrical components.

When opening and closing the gate leaf make sure that there

are no people, especially children or objects in its way.

Do not allow children to play with the equipment.

Gate control transmitters should be kept out of the reach

of children.

N

N

N

N

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

N

N

N

P

P

P

P

P

N

N

N

N

P

P

N

N

N

N

N

N

P

P

P

P

P

P

6. GATE INSTALLATION ERRORS

7. DISASSEMBLY OF THE GATE

8. MAINTENANCE INFORMATION

9. GATE OPERATING INSTRUCTIONS

in case of any faults they must be completely removed,

all activities should be carried out following the gate operating and

maintenance instructions.

3

Operating and Installation Instructions - MakroPro 100, MakroPro Alu 100 - installation type STL HLP

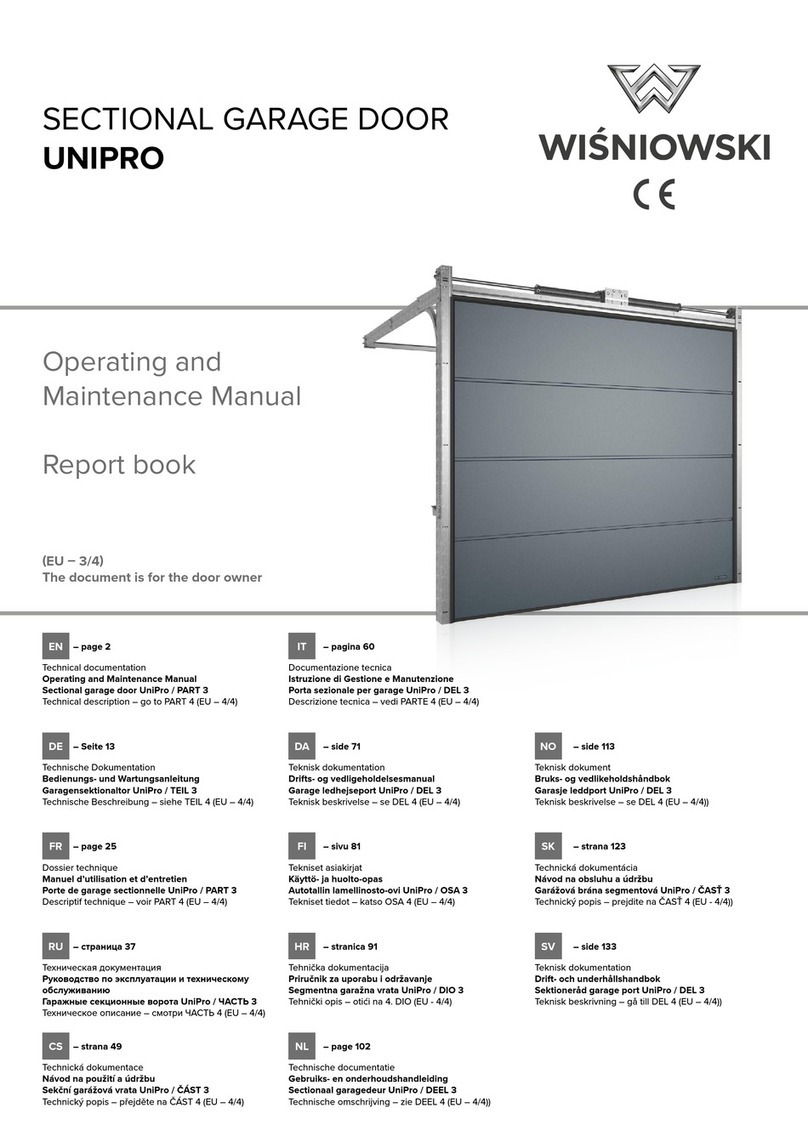

Operating and Maintenance Manual