C4028

Spring

Retainer

Bracket

IF CHANGING BOTH SPRING DIRECTION & OPERATOR

HAND (FROM LHR TO RHR OR RHR TO LHR) :

A. After changing spring direction, as outlined above, follow

steps on next page for changing operator hand.

B. After both tasks are done, reverse motor leads at

potentiometer ( see Operator Adjustments, Section #9 ).

IF CHANGING SPRING DIRECTION FROM LH TO LHR

OR RH TO RHR ( INSWING TO OUTSWING ):

A. After spring is removed, turn upside-down and replace on

output shaft (after shaft has been rotated 1/4 turn). Be

careful to place inner spring hook in same slot in shaft as

before.

B. Reinstall the rest of the assembly as outlined in steps B

thru D ( left ).

C. Reverse motor leads at potentiometer ( see Operator

Adjustments, Section #9 ).

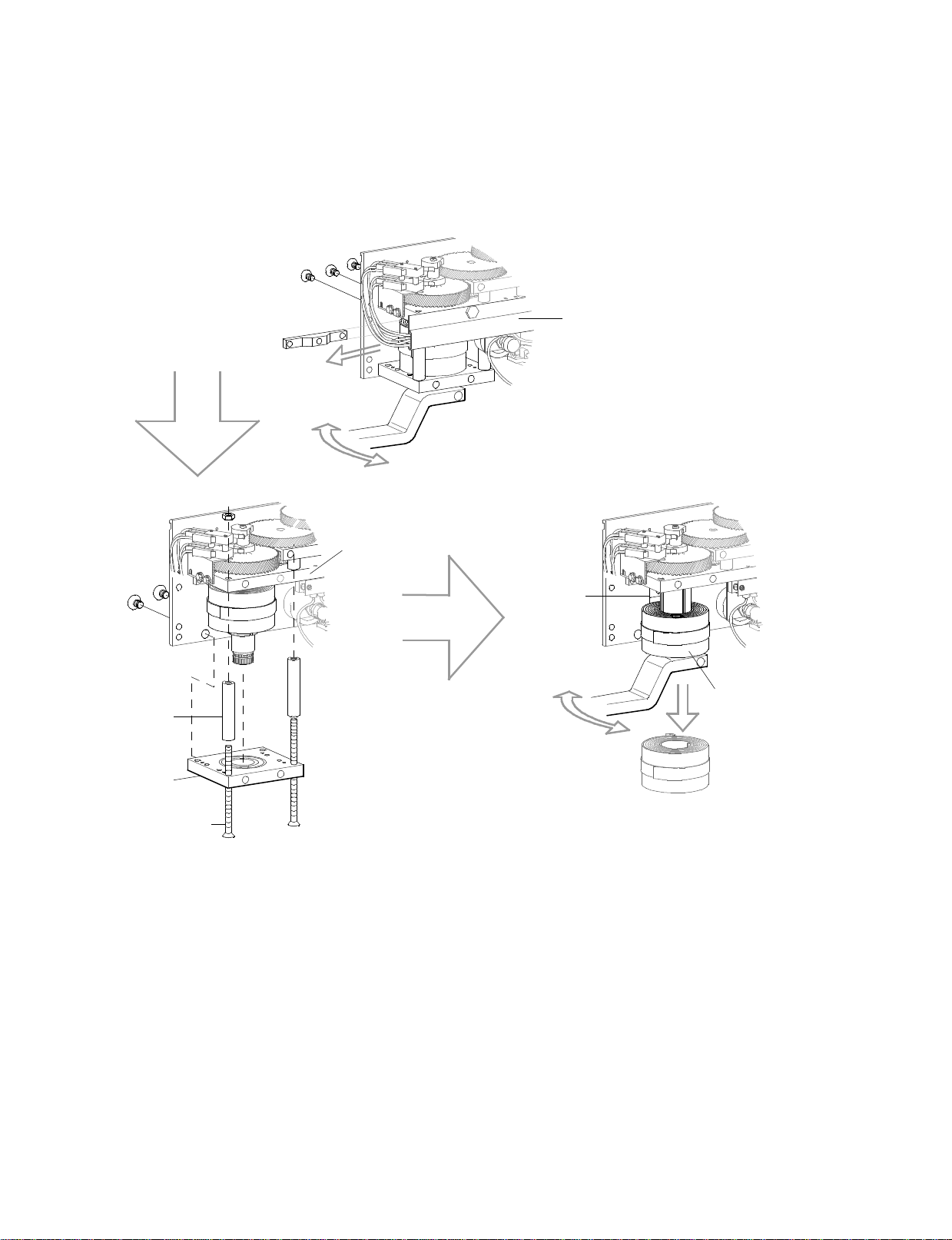

4th Step

Remove the two

assembly bolts, spacers

& lower bearing plate.

Note: Before proceeding

to next step, be carefull to

note location of inner

spring hook in output

shaft, as well as, the

direction the spring is

wound.

IF SPRING WAS BROKEN:

A. Replace new spring on output shaft. Be careful to place

inner spring hook in same slot in shaft as before.

B. Reinstall lower bearing plate with it's assembly bolts,

spacers and mounting screws.

C. Slide arm on output shaft and manually rotate until the

outer spring hooks clip into the spring retainer bracket.

Next rotate the shaft approximately 1/2 turn (180°) and

hold in that position.

D. Reinstall chassis stop and secure with mounting screws.

Allow arm to slowly counter-rotate until the stop lug on

the output shaft rests against the chassis stop. The

spring is now preloaded for most general applications.

7.070d1

C7132

Lower Bearing

Mounting Plate

C7078

1/4-20 x 4"FHMS

C7043-1 Spacer

1/2"O.D. x 2 1/2"

C7079

1/4-20 x 4 1/2"FHMS

5th Step

Slide an arm back

on the operator

shaft and manually

rotate until outer spring hooks release from

spring retainer bracket. Slide arm off and

remove spring.

ClosingSpring:

C7050 Type'D',

C7051Types 'E'.

The following information is provided as a guide for:

• Removing and replacing a broken spring.

• Changing spring direction.

• Changing both spring direction and operator hand.

• Changing operator hand but not spring direction.

NOTE: IN ALL CASES, SECURE THE BASE PLATE OF THE GEAR TRAIN ASSEMBLY (PREFERABLY IN A VISE)

WITH THE OUTPUT SHAFT FACING UP.

10. CHANGING OPERATOR HAND AND/OR CLOSING SPRING

1st Step

Slide an arm on the operator shaft and manually rotate arm

approximately 1/4 turn to relieve pressure on chasis stop.

Hold in that position.

2nd Step

Remove three chassis mounting screws

thus allowing spring to slowly unwind

and push out the chassis stop.

Remove both arm and

chassis stop.

3rd Step

Remove the two screws for lower

bearing mounting

plate.

C576

5/16-18 x 1/2"

FHMS

C7130-1

Upper Bearing

Mounting Plate

C7037

Chassis

Stop

REMOVING THE SPRING:

C576

1/4-20 x 3/4"

FHSCS

G710.6

Optional Step

To clear work space, detach C7083

Wire Guide & Operator Wiring

Harness from upper bearing plate

and move out of way.