ENGLISH IMPORTANT SAFETY INFORMATION .................................................................................................. 1

I. INSTALLATION INSTRUCTIONS ..................................................................................................... 3

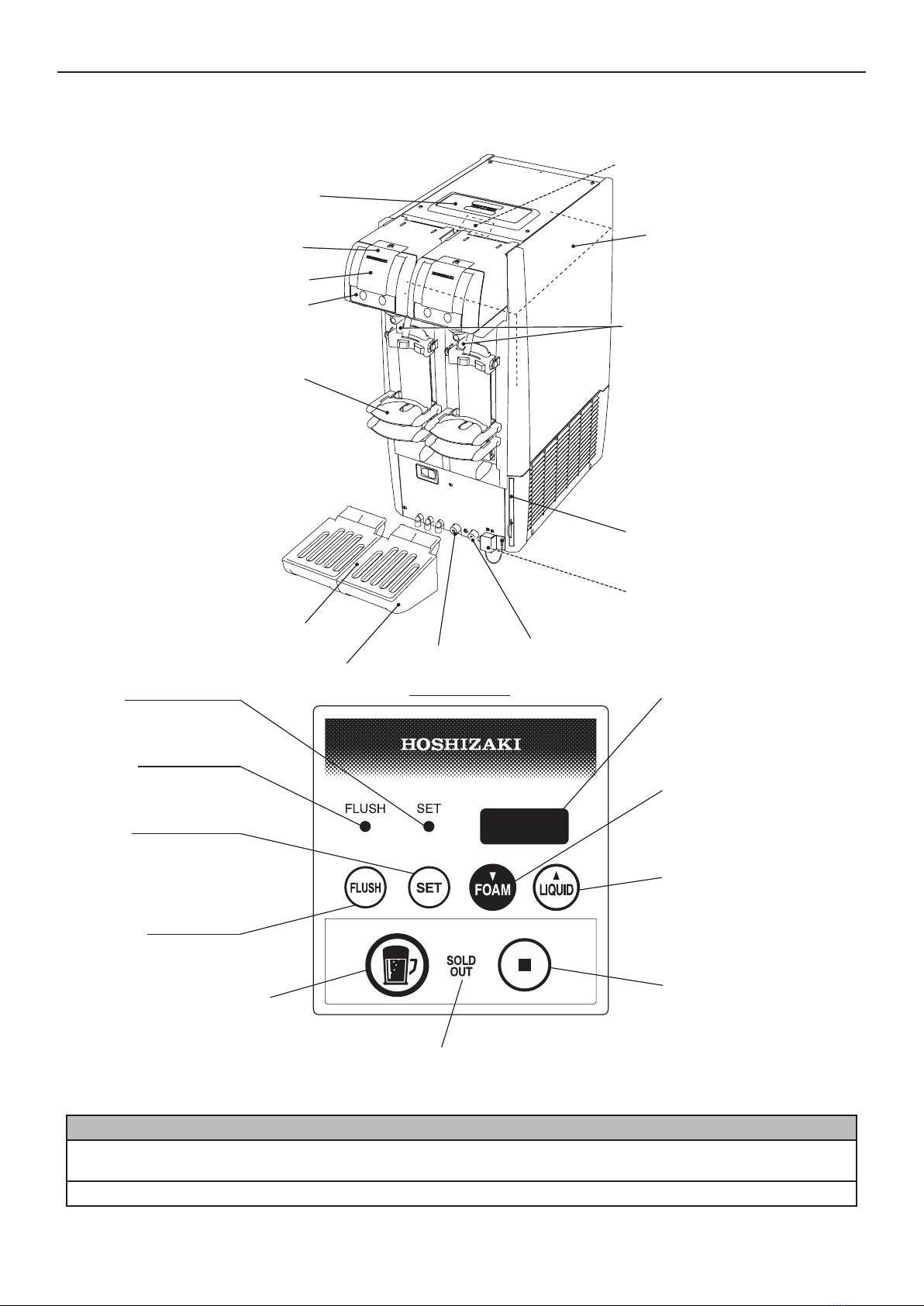

1. CONSTRUCTION ........................................................................................................................ 3

2. ACCESSORIES ........................................................................................................................... 4

3. UNPACKING................................................................................................................................ 4

4. LOCATION................................................................................................................................... 5

5. INSTALLATION............................................................................................................................ 5

[a] DISPENSER............................................................................................................................ 6

[b] DRAIN PAN............................................................................................................................. 6

[c] PLATFORM ADJUSTMENT.................................................................................................... 7

6. ELECTRICAL CONNECTIONS.................................................................................................... 9

7. GAS AND BEER CIRCUIT CONNECTIONS ............................................................................... 9

[a] CO2 GAS CYLINDER ............................................................................................................. 9

[b] HOSE CONNECTIONS ........................................................................................................ 10

[c] CHECKS AFTER CONNECTIONS ....................................................................................... 10

8. CHECKS AFTER INSTALLATION............................................................................................. 11

9. SOLD OUT SENSOR SETTING (“U07”).................................................................................... 11

10. USER SETTINGS ...................................................................................................................... 12

II. OPERATING INSTRUCTIONS........................................................................................................ 13

1. CLEANING BEER CIRCUIT....................................................................................................... 13

2. FILLING WATER TANK ............................................................................................................. 13

[a] HOW TO MAKE COOLING WATER..................................................................................... 13

[b] COOLING WATER SUPPLY................................................................................................. 14

3. CHECKS BEFORE OPERATION (DAILY)................................................................................. 14

[a] CHECKING CO2 GAS CYLINDER ....................................................................................... 14

[b] REPLACING CO2 GAS CYLINDER ..................................................................................... 14

[c] CHECKING BEER KEG ........................................................................................................ 15

[d] REPLACING BEER KEG ...................................................................................................... 15

4. START UP.................................................................................................................................. 16

[a] SWITCHING MODE.............................................................................................................. 16

[b] LEADING BEER TO TAP...................................................................................................... 16

5. SETTING LIQUID AND FOAM AMOUNTS................................................................................ 16

[a] LARGER MUG SETTING...................................................................................................... 17

[b] SMALLER MUG SETTING.................................................................................................... 17

6. DISPENSING ............................................................................................................................. 17

[a] AUTOMATIC DISPENSING.................................................................................................. 17

[b] STOPPING AUTOMATIC DISPENSING .............................................................................. 18

[c] MANUAL DISPENSING ........................................................................................................ 18

[d] SWITCHING TO AUTOMATIC DISPENSING MODE........................................................... 19

7. SOLD OUT SENSOR................................................................................................................. 19

8. END OF DISPENSING OPERATION ........................................................................................ 19

9. SHUT DOWN ............................................................................................................................. 19

[a] SHUT DOWN ........................................................................................................................ 19

[b] DRAINING WATER TANK .................................................................................................... 20

III. MAINTENANCE............................................................................................................................... 20

1. BASIC CLEANING ..................................................................................................................... 20

2. BEER CIRCUIT (DAILY) ............................................................................................................ 21

3. DRAIN PAN AND GRILLE (DAILY)............................................................................................ 22

4. PLATFORM (DAILY).................................................................................................................. 22

5. CLEANING BEER CIRCUIT WITH SPONGE (WEEKLY).......................................................... 23

6. DISASSEMBLY AND CLEANING OF BEER TAP (WEEKLY)................................................... 25

7. KEG COUPLER (WEEKLY)....................................................................................................... 26

8. EXTERIOR (WEEKLY)............................................................................................................... 26

9. AIR FILTER (BIWEEKLY) .......................................................................................................... 26

IV. INSPECTION................................................................................................................................... 26

1. COOLING WATER AND ELECTRODE (BIANNUALLY) ........................................................... 26

2. GAS HOSE AND BEER HOSE (MONTHLY)............................................................................. 27

3. ATTACHMENT PLUG AND POWER CORD (ANNUALLY / BIANNUALLY) ............................. 27

V. OTHER INFORMATION .................................................................................................................. 27

1. PREPARING THE DISPENSER FOR LONG STORAGE.......................................................... 27

2. BEFORE CALLING FOR SERVICE........................................................................................... 28

3. DISPOSAL ................................................................................................................................. 29

4. WARRANTY............................................................................................................................... 29

SPECIFICATIONS................................................................................................................................. 30