5

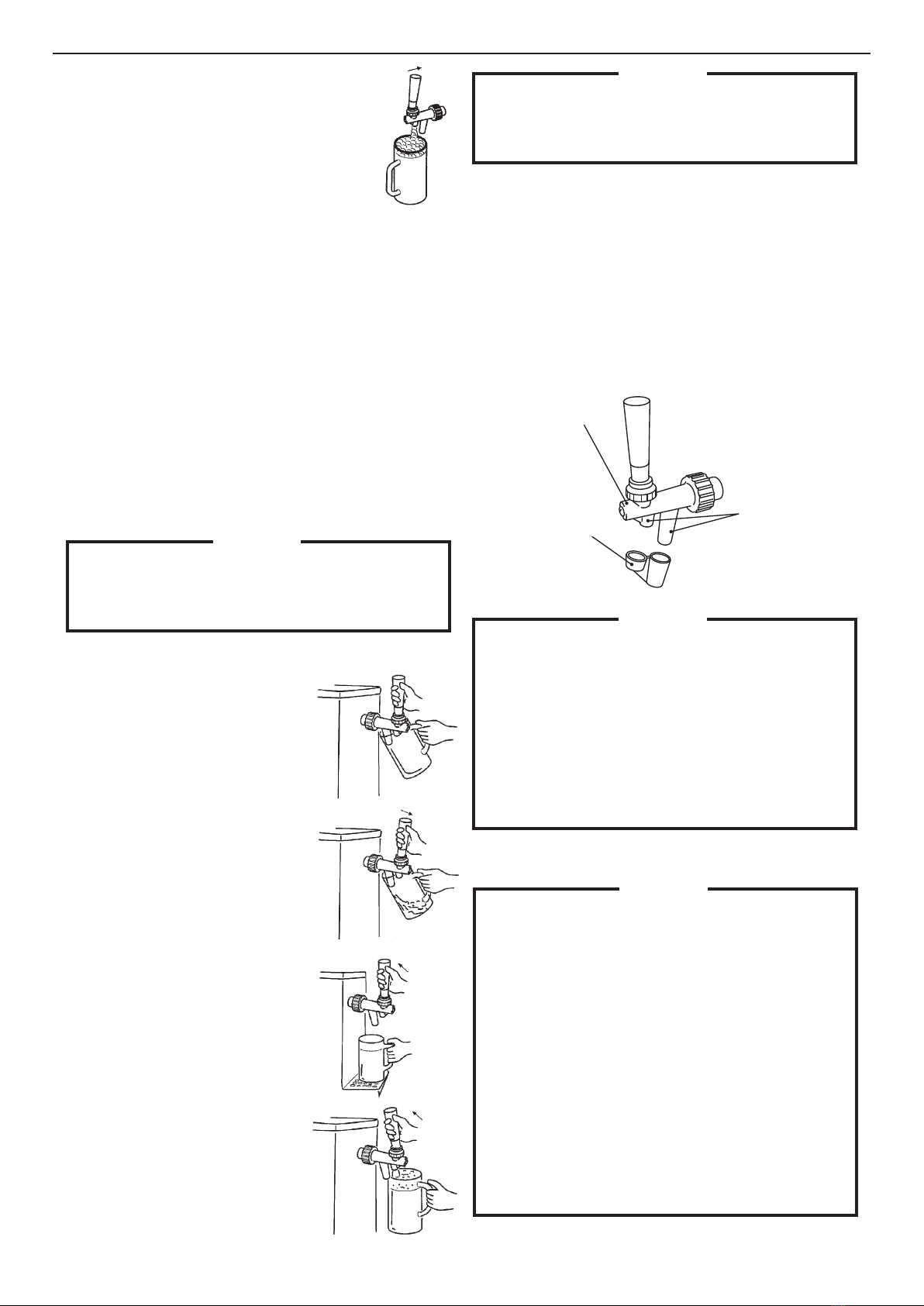

[b] LEADING BEER TO TAP

1)Checkthattheregulatoradjustdialissettotheappropriate

pressurespeciedbythebeercompany.

2)Check that the beer tap lever is closed. Opening the keg coupler

withthebeertapleveropenwillcausebeertosplashout.

3)Openthekegcoupler.

4)Set a mug to receive beer, and push the beer tap lever hard to

theback(foamposition).Keeppushingittodispensefoam.When

themugishalflledwithfoam,movetheleverbacktoitsoriginal

positiontostopfoam.

5)Waitformorethan1minuteafterstep4)tosettlebeerinthecircuit.

6)Setanothermug,andpullthebeertaplevertowardyouto

dispensebeer.Keepdispensingbeeruntilfoamturnsintoliquid.

7)Checkthekegcouplerandkegconnectionandthebeerhosejoints

forbeerleaks.

IMPORTANT

Frequently dump water and beer from the drain pan. The

coolingwaterinthewatertankwillincreaseinvolumebytaking

moisturefromtheair,andcomeoutthroughtheoverowhose

intothedrainpan.Ifleftasitis,waterwillowoutofthedrain

panontotheoor.

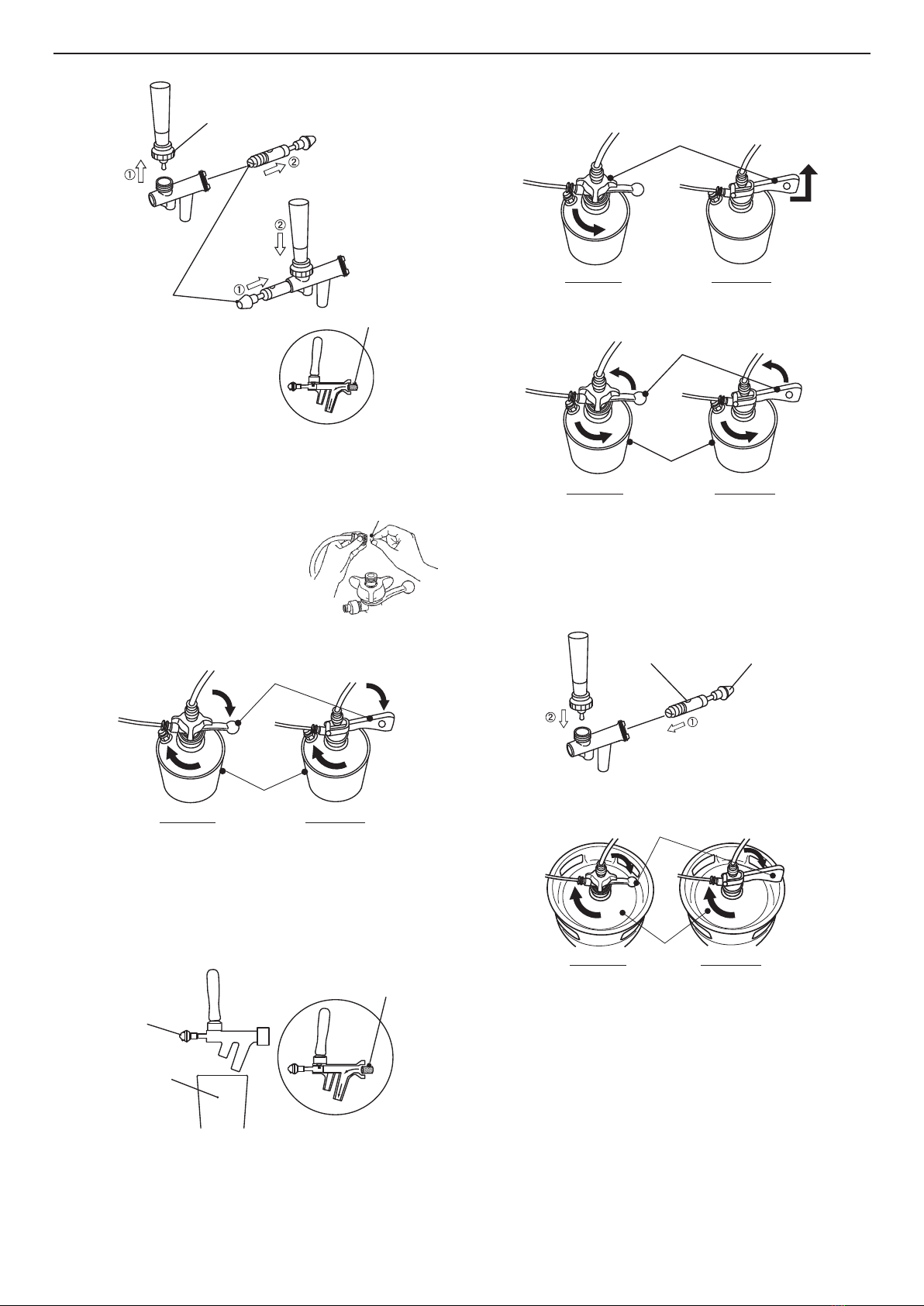

[c] DISPENSING BEER

3)Todispensefoam,pushthebeertapleverhard

toward the unit from the stop position. To stop

foam,movetheleverbacktoitsoriginalposition.

IMPORTANT

Ifthebeercircuitisnotflushedwithbeerremainingonthe

beertap, thevalve shaftjams insidethe beer tap, resulting in

unavailable,unstable,orcontinuousdispensingactions.Inthis

case,disassembleandcleanthebeertapinaccordancewith“III.

5.DISASSEMBLYANDCLEANINGOFBEERTAP(WEEKLY)”.

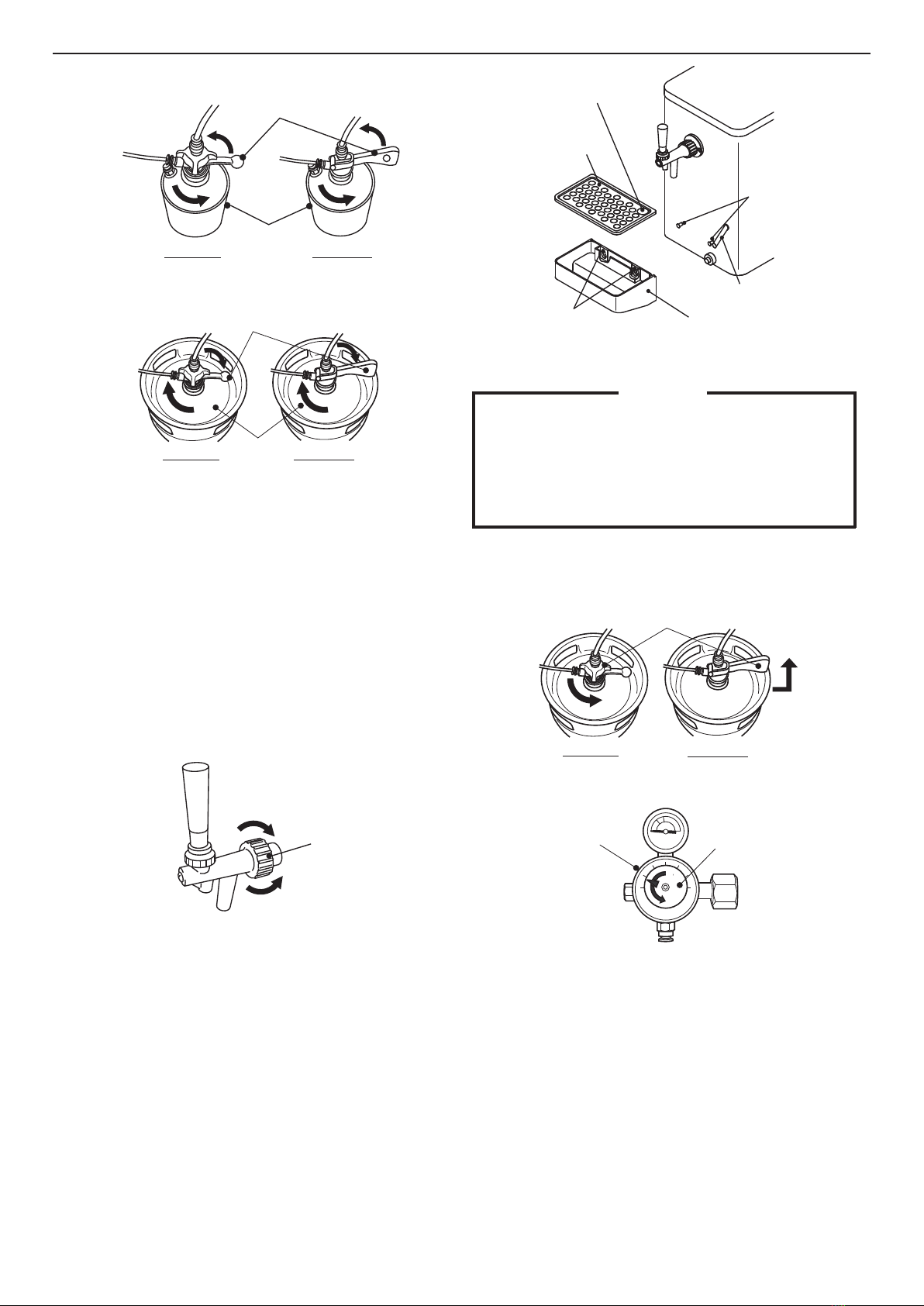

[d] END OF OPERATION

1)Closethekegcoupler,andremoveitfromthekeg.Flushthebeer

circuit according to “III. 1. BEER CIRCUIT (DAILY)” and “III. 4.

CLEANINGBEERCIRCUITWITHSPONGE(WEEKLY)”.

2)Turntheregulatoradjustdialcounterclockwiseto“0”.

3)ShutofftheCO2gascylinderbyturningthemainvalveclockwise.

4)Wipe moisture from the nozzle end. Wash the nozzle cap clean,

andfititonthenozzle.Thenozzlecapmustberemovedand

storedinacleanplaceduringoperation.

Fiton

Beertap

Nozzle

Nozzlecap

1)Tiltacleanmugatan angle of45°,and

placeitsinnersurfaceincontactwiththe

liquidnozzleofthebeertap.

2)Pullthebeertaplevertowardyouto

dispense beer over the inner surface of

themug.

3)Afterdispensingaspecificamountof

beer,movethebeertapleverbacktoits

originalpositiontostopbeer.

4)Toadd foam,push thebeer tap leverto

the back. Foam will keep coming out of

thefoamnozzleofthebeertapwhilethe

leverispushed.Tostopfoam,movethe

leverbacktoitsoriginalposition.

IMPORTANT

1. To preventexcessive mixtureof CO2 gasin draftkeg beer,

besure toclose themain valveof theCO2 gascylinder at

theendofoperation.

2.Theaccessorynozzlecapprotectsthebeertapnozzle

againstdustorinsectswhilethedispenserisnotused.

Alwayscapthenozzleattheendofoperation.

3. When the keg coupler on the keg is closed, gas may stay

insidethebeercircuit.Topreventexcessivefoamingor

improper dispensing actions, lead beer into the beer circuit

untilgascomesoutofthebeertapbeforestartingoperation

onthefollowingday.

III. MAINTENANCE

IMPORTANT

1.Afterclosingtime,besuretocarryoutthefollowing

maintenanceprocedures.

2.Followthemaintenanceinstructionsbelowwhenever

considerednecessary.

3. Incleaningoperations,becarefulnotto loseanyparts.The

unitwillleakwaterorfailtodispenseproperly.

4.Alwaysusecleanhandsandclothstoconductcleaning

operations.

5. Asasanitizer,useamixtureofwarmwater(30-40°C)and

10 mL of 10% invert soap (benzalkonium chloride). Before

usingthesanitizer,thoroughlyreadtheinstructionsprovided.

6.Topreventdamagetotheplasticsurfaces,donotuse

thinner,benzine,petroleum,soappowder,polishingpowder,

alkaline detergent, scrub brush, and especially cleanser for

useonfansandcookingranges.Also,topreventcorrosion,

donotuseachlorinebleach(sodiumhypochlorite).