2

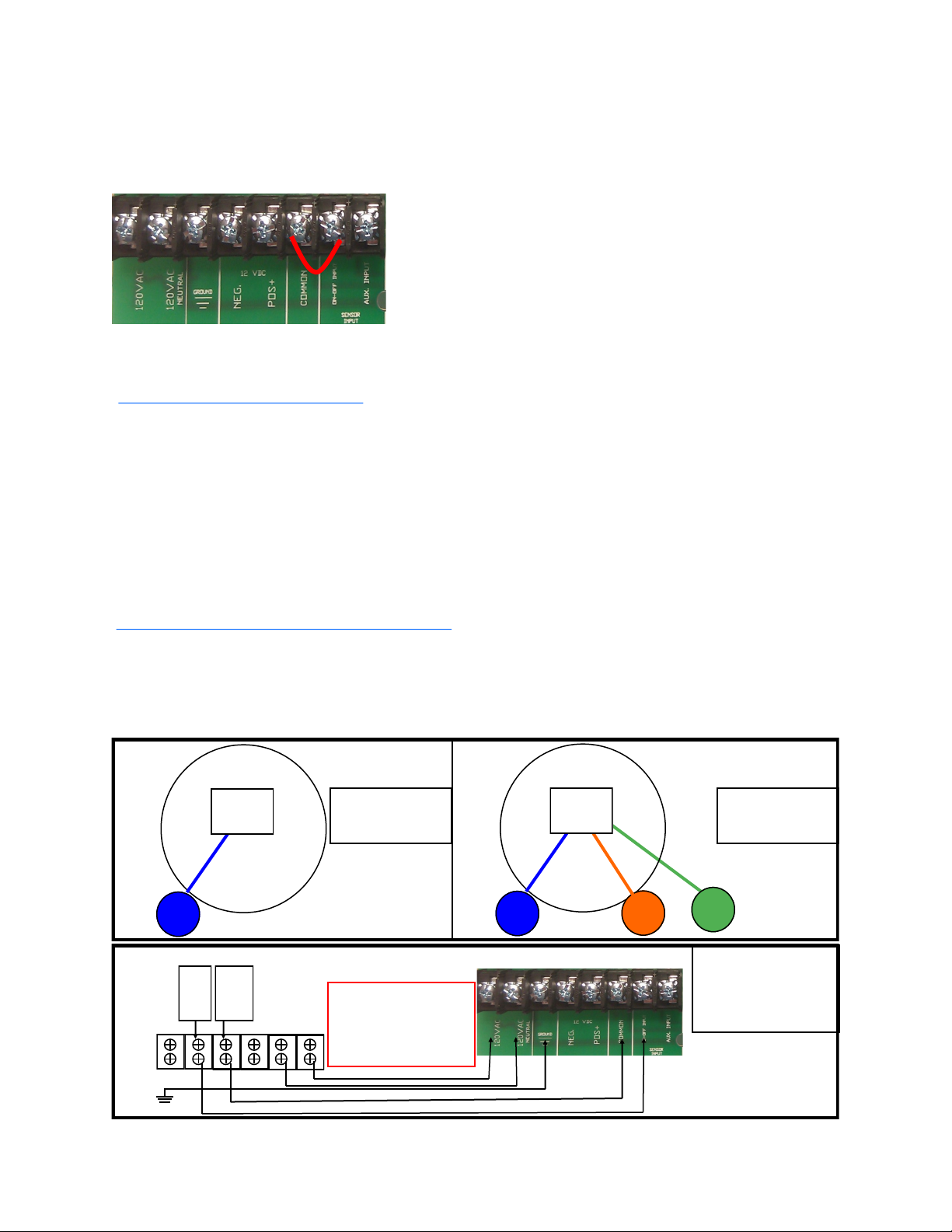

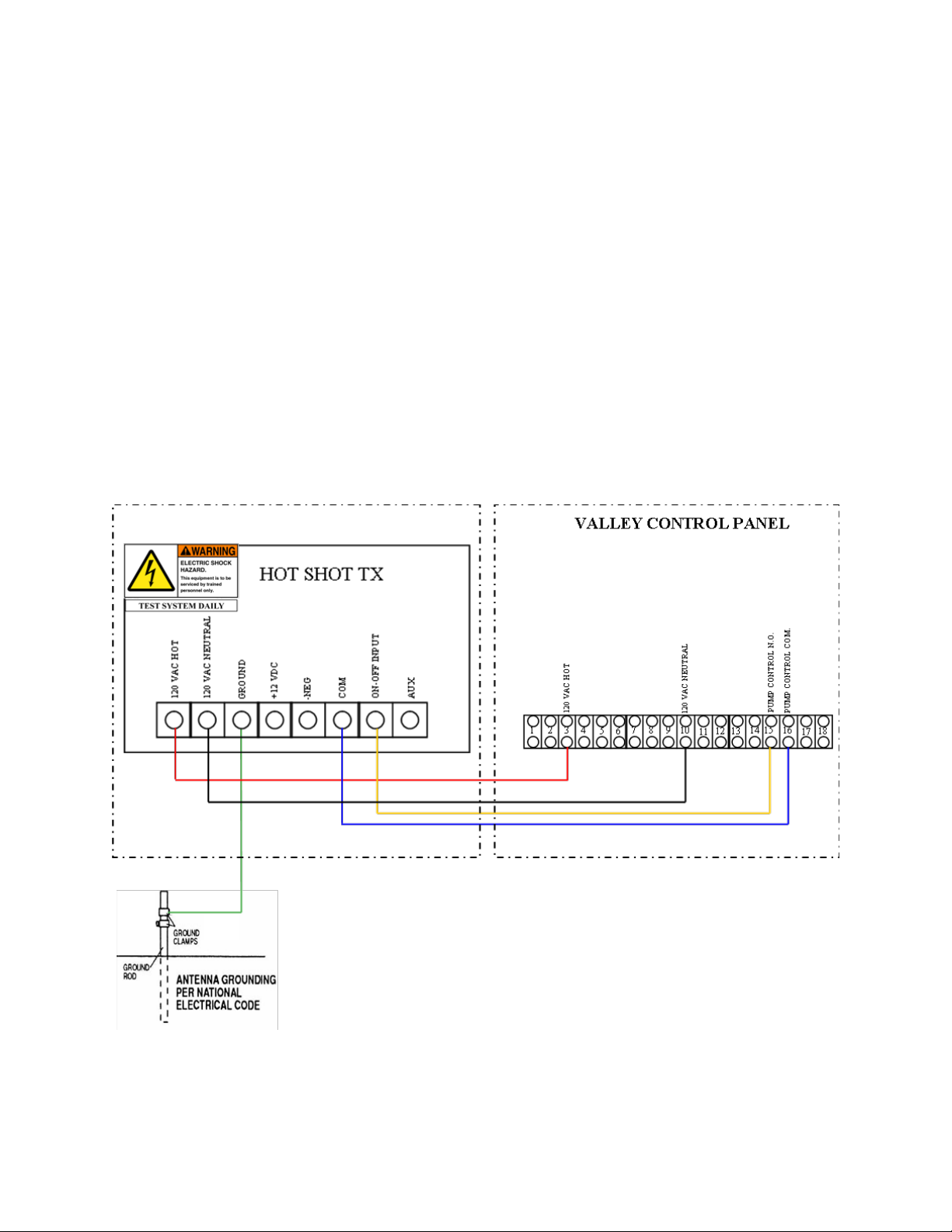

CAUTION: Never connect any voltage to the HOT SHOT SENSOR Input terminals. The Hot Shot sup-

plies the voltage needed for sensor switching (use dry relay contacts only). Make sure the pivot’s well kill

terminals do not have voltage from previously wired configurations.

ATTENTION: Depending upon the style of system that your are going to control with the Hot Shot

Wireless Controller you may need to supply additional parts. Such as relays, step-down transformers, Mur-

phy switches etc. These items are suggested in the wiring guides that follow in this manual.

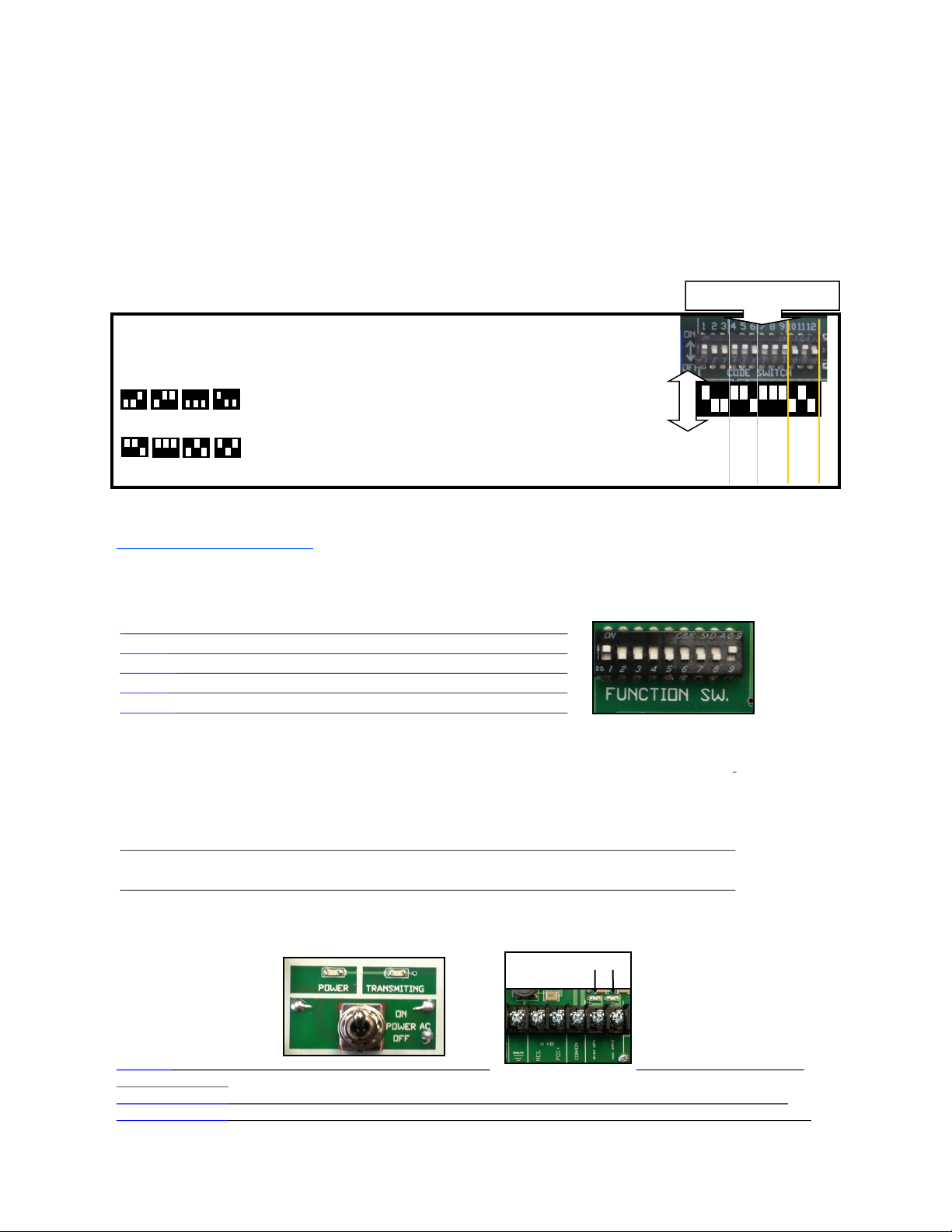

HOW IT WORKS

Think of the HOT SHOT system as a control wire going from the transmitter site to the receiver site. When the

Hot Shot Transmitter’s SENSOR ON-OFF Input is connected to COM, a small delay timer is started. After the

delay timer has expired, the transmitter will send the (Relay ON) command to the receiver. This will close the

relay contacts between N.O. and COM. When the SENSOR ON-OFF input at the transmitter is opened it will send

the (Relay OFF) command to the receiver switching the relay back to N.C. connected to COM. Battery backup in

the transmitter will still allow the HOT SHOT to work in case of power outage. Each system is coded with its own

four digit code so it will not interfere with other systems in the same area. The following manual has been pre-

pared to provide details for Transmitter installation on electric and engine driven pivots.

MOUNTING

Cabinets are a weatherproof UV protected NEMA 4X cabinet with mounting ears on top and bottom. The trans-

mitter/receiver control box can be mounted on the side of a control panel, pole or any other surface as long as the

antenna does not have metal running within 12” of the antenna whip. If longer range is needed, an external long

range antenna can be used. Do not mount the HOT SHOT receiver to the well engine or cover because the strong

vibrations can be harmful to the unit.

If installing these on a Variable Frequency Drive pump do not mount the receiver unit to the VFD because of the

potentially strong magnetic field interference that can be produced by these drives. The further away it is mounted

the better it is for the Hot Shot Unit.

BATTERY BACKUP

During a power outage, a gel cell rechargeable battery supplies power to the transmitter for approximately 24

hours. This allows the transmitter to send a shutdown signal to the receivers when the pivot has lost power. The

Hot Shot Transmitter comes with a battery save feature that will turn off the Hot Shot Transmitter if the voltage

drops from 12vdc to 10vdc. This function will add years of life to the gel cell battery.

Important... When the battery has discharged, it will take approximately 2 to 3 hours for the battery to

charge enough to operate the transmitter in case of another power failure. The battery should be replaced

every year for the best reliability during power outages.

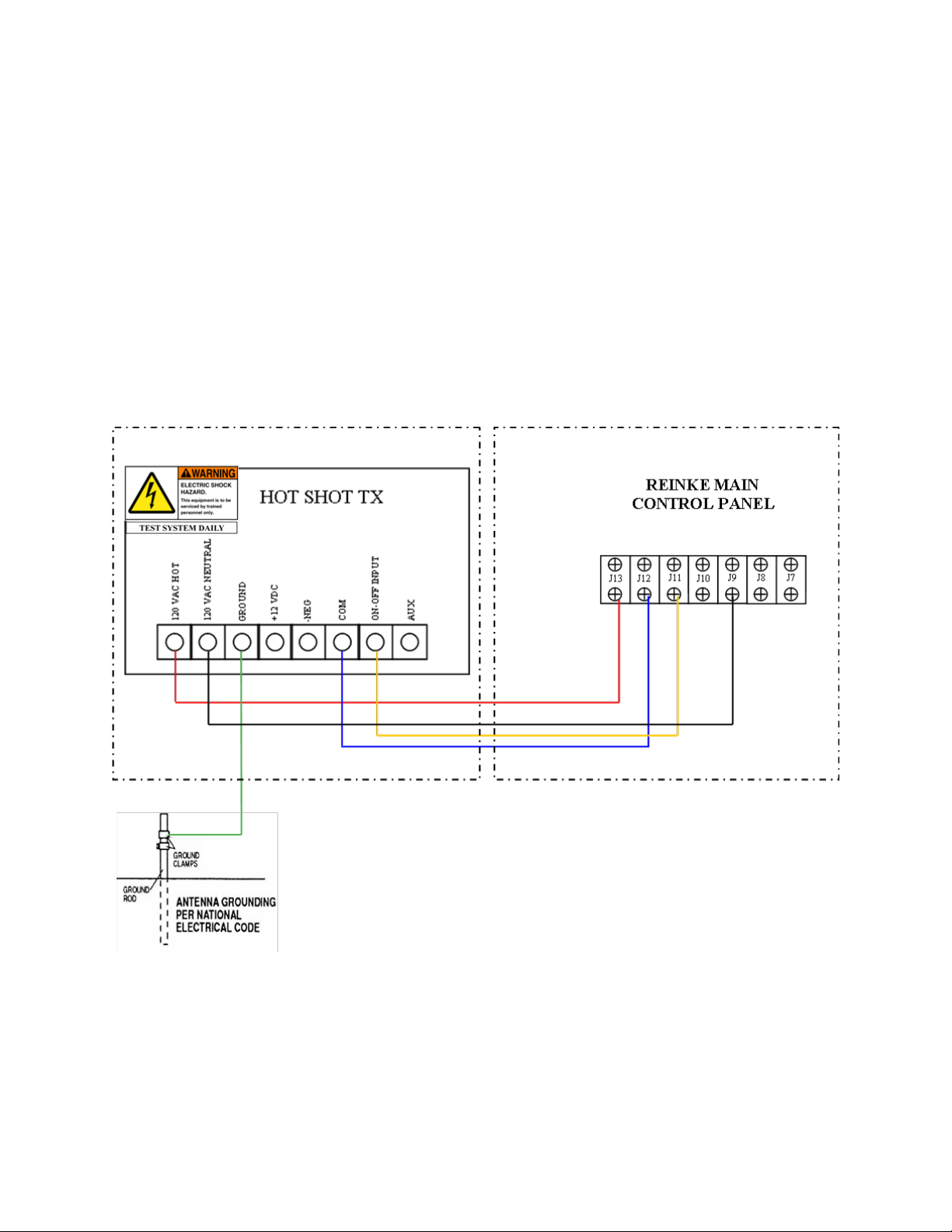

ATTENTION: All Hot Shot units have a designated GROUND Terminal. Hot Shot units must have

there ground terminal connected to a proper ground or grounding system as per the NEC (National Electri-

cal Code) and or your local and state electrical code guidelines.