Page7Hotsy 1065A/1065SS

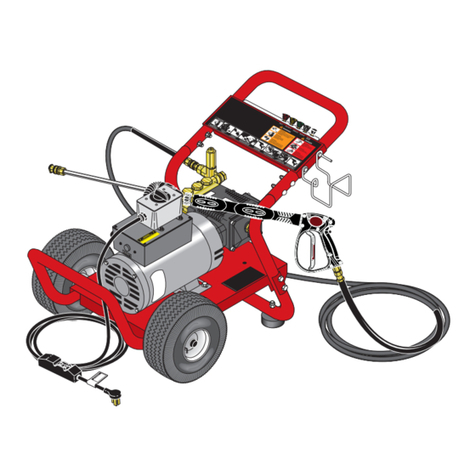

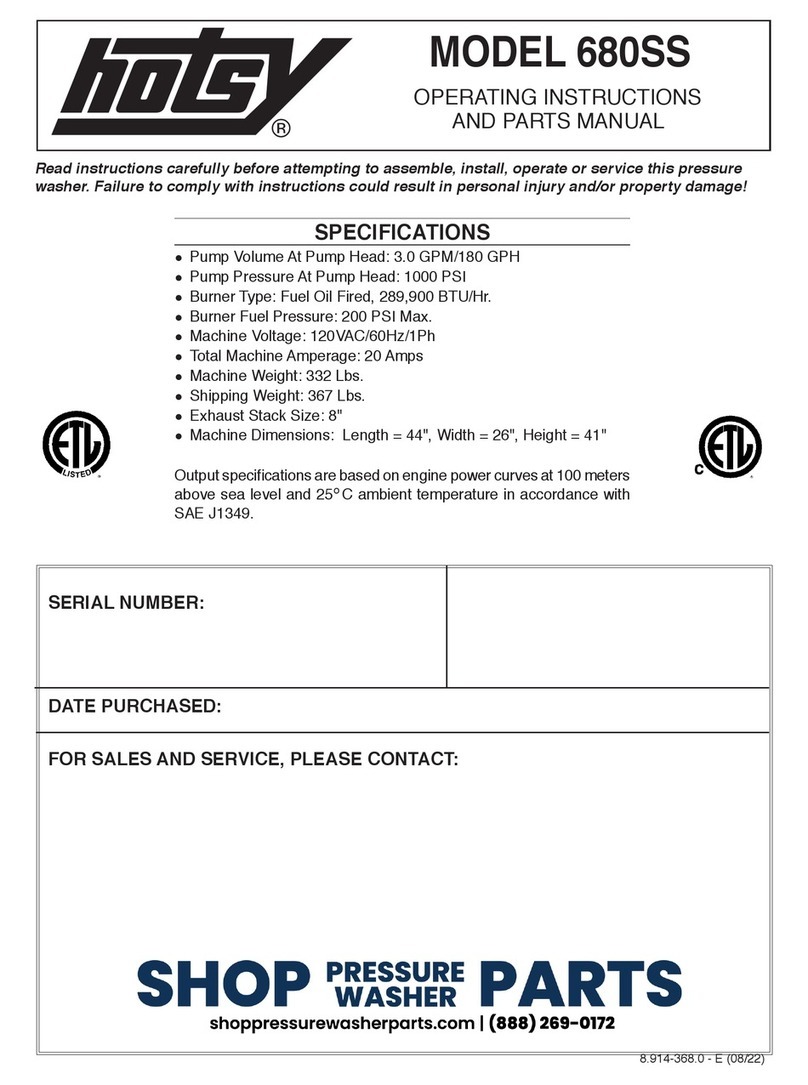

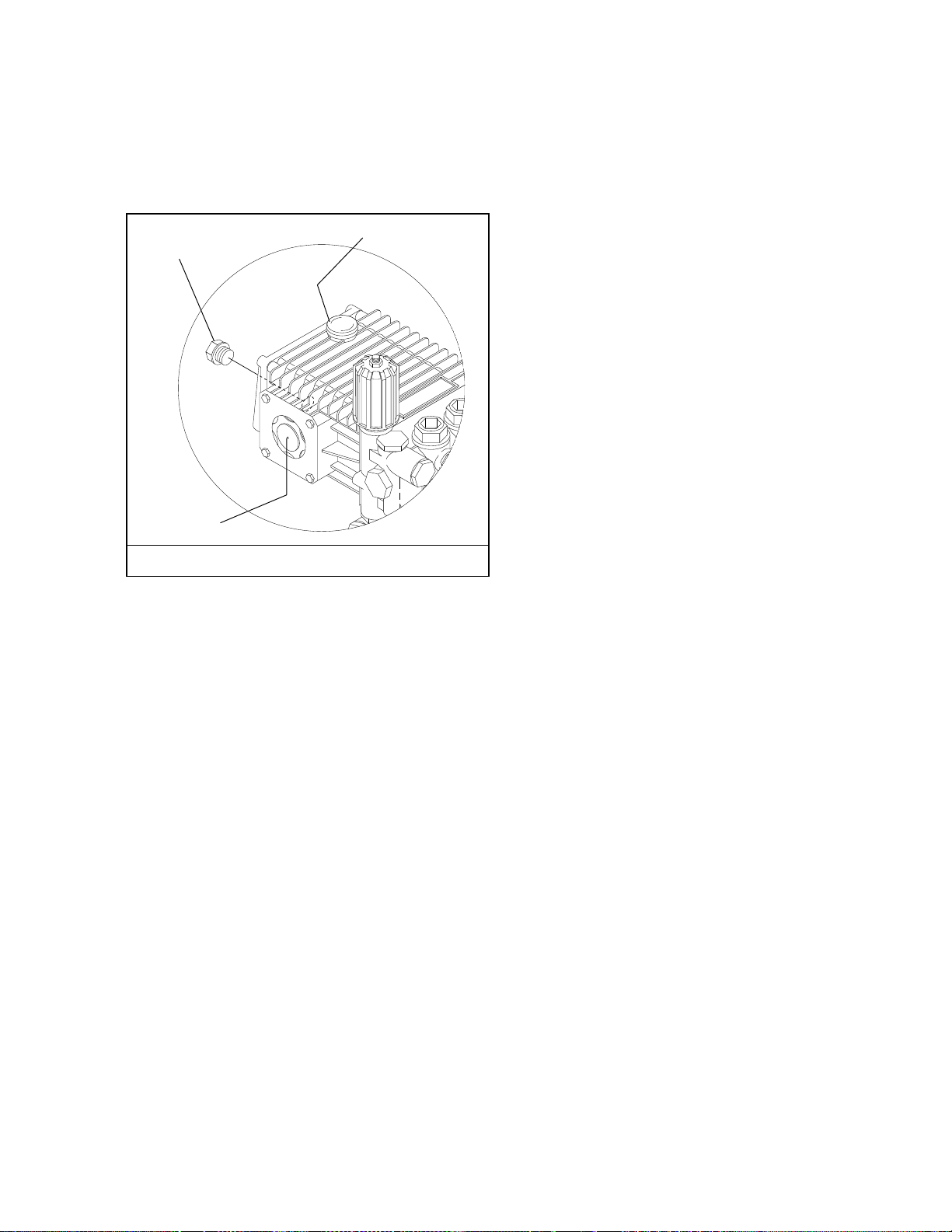

Figure 8 - Detergent Injector Valve

DETERGENT CONTROL KNOB

WATER ADJUSTMENT KNOB

DETERGENT

ON

DETERGENT

OFF

WATER

DECREASE WATER

INCREASE

IMPORTANT:The trigger gun provided with this pres-

sure washer is equipped with a manual trigger lock

to prevent accidental operation of the trigger gun.

(Refer to Figure 7.)The manual trigger lock should be

used whenever the trigger gun is not in use.

To Start

DANGER:DO NOT point wand or trigger gun at your-

self or at any person. Bodily injury may result from

water under high pressure.

WARNING:Wear eye, ear, hand, foot and skin protec-

tion at all times while operating pressure washer.

IMPORTANT:The watermust beturned on beforestart-

ing. Running the pump dry will cause damage and

void warranty.

IMPORTANT: DO NOT allow the machine to run with

trigger of the trigger gun released for more than

10 minutes at any one time or damage to pump may

occur.

1. Turn ON water supply.

2. Hold wand firmly, release trigger of trigger gun.

3. Place engine ON/OFF switch in the ON position.

4. Open fuel shutoff valve (if so equipped).Move choke

lever to FULL CHOKE position, (choke may not be

neededonwarm engine).Move throttle levertoHALF

THROTTLE position.

5. Pulltheropestarter slowlyuntilresistance is felt,then

pull briskly.Do not allow the rope starter to snap back

against the engine. Return it gently to prevent dam-

age to the starter.

6. When the engine starts, move choke lever until

engine runs smoothly. When engine warms, move

choke lever to NO CHOKE position. Move throttle

lever to FULLTHROTTLE position.

IMPORTANT:To allow for proper battery charging,the

throttle control must be kept in the full throttle posi-

tion during operation.

NOTE:If engine fails to start, refer toTroubleshooting

Guide in this manual.

7. Squeeze trigger of trigger gun and allow air to purge

from system.

8. If HOT water is desired, adjust the thermostat to the

proper temperature and turn burner switch ON.The

burnerwilllightimmediatelywith asmallpuff ofsmoke.

You may need to initially adjust your burner for peak

performance.SeeOil Burner sectionunderInstalla-

tion.If smoke continues, contact Customer Service

at 1-303-792-5200. When the trigger of the trigger

gun is released or when the thermostat temperature

setting is reached, the burner will automatically turn

off.

To Clean

DANGER: DO NOT place hands or fingers in front of

high pressure spray. Bodily injury may result.

The detergent injector valve operates by reducing the

volumeofwater,thusavacuumis achievedand detergent

is drawn into the system.DO NOT reduce the water inlet

flow so the pump cavitates due to water starvation.

Operating a pump with insufficient water will damage

the pump seals.

1. Insert detergent inlet line into container of mixed

detergent.

2. Completely open detergent control knob located on

the side of the detergent injector valve. Refer to

Figure 8.

3. Start the detergent suction by rotating the water

adjustment knob of the detergent injector valve.

Referto Figure 8.Turning the knob counterclockwise

will pull detergent into the system. The flow may be

observed through the clear detergent line.Secure the

knob position with the knurled nut.

4. Thesidedetergentcontrol knob can nowbe adjusted

to meter the desired amount of detergent.

5. Wash from the bottom to the top, using side to side

motions.This washes away heavy dirt and allows the

detergent to soak as you work toward the top.

6. Do not wash at a 90oangle to the work (straight at it).

This will allow water to splash back at you and

reduces your cleaning power. Wash at a 30oto 60o

angle to the work.This will allow the water to splash

away from you and the water will wash the dirt away

faster and easier.

7. Use the width of the spray pattern to wash in a wide

path. Overlap spray paths for complete coverage

washing from side to side, using slow, steady

motions.