Page7Hotsy 781SS, 871SS, 921SS • 97-6642 • Rev.9/04

14. Hotsy will not be liable for any changes made to

ourstandardmachines,oranycomponentsnotpur-

chased from Hotsy.

15. Read engine safety instructions provided.

16.Neverrunpumpdryorleavetriggergunclosedlonger

than 5 minutes.

17. Inlet water must be from a cold, clean fresh city

watersupply. WARNING: Only use recom-

mended fuel. Using other fuels

mayresult inaserious explosion

causing personal injury, prop-

erty damage or loss of life.

18. Use No.1 or No.2 heating oil

(ASTM D306) only. NEVER

use gasoline in your fuel oil

tank. Gasoline is more com-

bustiblethanfueloilandcould

result in a serious explosion. NEVER use crank-

caseorwasteoil in yourburner assembly.Fuel unit

malfunctioncould result from contamination.

19. Do not confuse gasoline and fuel oil tanks. Keep

properfuel in propertank.

20. Protect machine from freezing.

21. Be certain all quickcoupler fittings are securedbe-

fore usingpressure washer.

22. Do not allow acids, caustic or abrasive fluids to

passthrough the pump.

23. Toreducetherisk of injury,closesupervision is nec-

essarywhena productisusednearchildren.Donot

allow children to operate the pressure washer.This

machinemustbe attended during operation.

24. Donotoperatethisproduct when fatigued orunder

the influence of alcohol or drugs. Keep operating

area clear of all persons.

25. Protect highpressure hose fromvehicle traffic and

sharpobjects.

26. Beforedisconnectinghighpressurehosefromwater

outlet,turnburneroffandpullthetriggeronthespray

gun allowing water to cool to below 100° F before

stopping machine.Then open the trigger gun to re-

lievepressure.Failuretoproperlycooldownormain-

taintheheatingcoilmayresultina steamexplosion.

27. Donotoverreachorstandonunstablesupport.Keep

good footing and balance at all times.

28. This machine must be attendedduring operation.

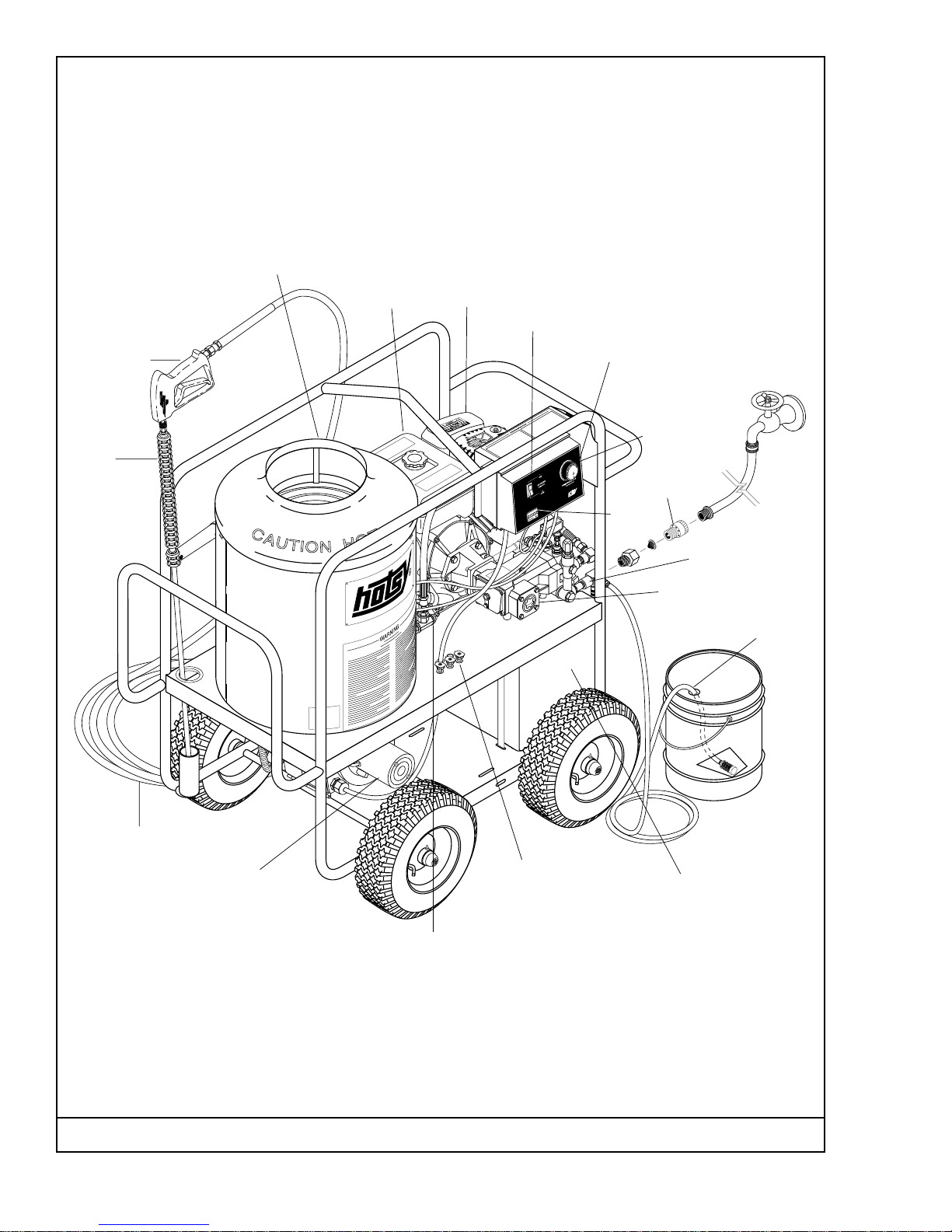

INSTALLATION

Getting Started

IMPORTANT: Proper initial installation of equipment

will assure more satisfactory performance, longer

service life, and lower maintenance cost.

IMPORTANT: The use of a backflow preventer on

the water supply hose is recommended and may be

required by local code.

The pressure washer should be run on a level surface and

in a protected area where it is not readily influenced by

outsideforcessuchasstrong winds,freezingtemperatures,

rain,etc.Thepressure washershouldbelocated to assure

easy access for filling of fluids, adjustments and

maintenance.Normal precautions should be taken by the

operator to prevent moisture from reaching the pressure

washer.Itisrecommendedthatapartitionbemadebetween

the wash area and the pressure washer to prevent direct

spray from the wand from coming in contact with the

pressure washer. Moisture reaching the equipment will

reduce the pressure washer’s service life. All installations

mustcomplywiththelocalcodescoveringsuchinstallations.

Venting

DANGER: DO NOT run machine indoors or in an

enclosed area, as exhaust fumes may be hazardous

to your health.

DANGER: DO NOT operate machine in areas where

flammable vapors (gasoline, solvents, etc.) may be

present, as this machine may ignite the vapors.

CAUTION: All venting must be in accordance with

applicable federal and state laws, and local ordi-

nances. Consult local heating contractors.

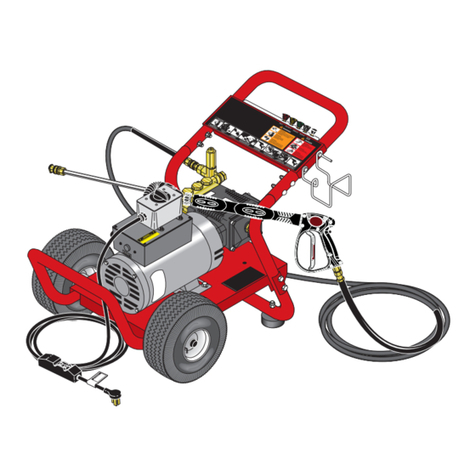

If the pressure washer is to be used in an enclosed area, a

flue must be installed to vent burner and engine exhaust

to the outside atmosphere. Be sure the flue is the same

size as the burner exhaust vent on the pressure washer.

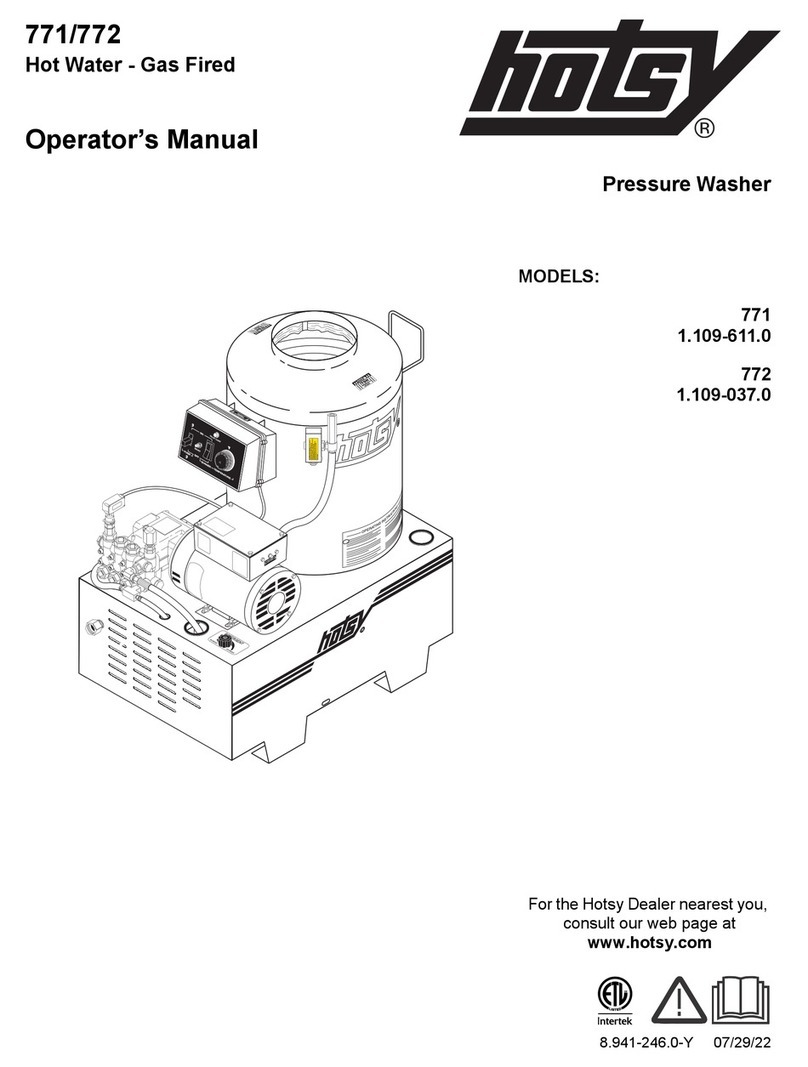

SeeFigure 1forlocation.Poordraftwillcausethepressure

washer to soot and not operate properly. When selecting

the location for installation, beware of poorly ventilated

locations or areas where exhaust fans may cause an

insufficient supply of oxygen. Proper combustion can only

be obtained when there is a sufficient supply of oxygen

available for the amount of fuel being burned. If it is

necessary to install the machine in a poorly ventilated

area, outside fresh air may have to be piped to the burner

and a fan installed to bring sufficient air into the machine.

Locate the pressure washer so that the flue will be as

straight as possible and protrude through the roof at a

proper height and location to provide adequate draft.This

oil fired pressure washer must have a draft regulator

installed in the flue (available from most heating

contractors). A draft regulator will permit proper upward

flow of exhaust flue gases.

In addition, the pressure washer should never be operated

inanenclosedareawherehighambienttemperaturesexist.

Highambienttemperatures(above100oF)cancauseengine

oil failure and will greatly reduce the engine’s performance.

Gasoline Engine

The gasoline engine is preset for operation at altitudes

below 3000 feet above sea level. If operated at higher

altitudes, it may be necessary to install a high altitude

main jet in the carburetor. Contact an authorized engine

sales and service center for details.

WARNING

RISK OF FIRE OR

EXPLOSION:USE

VAPORFUELONLY.