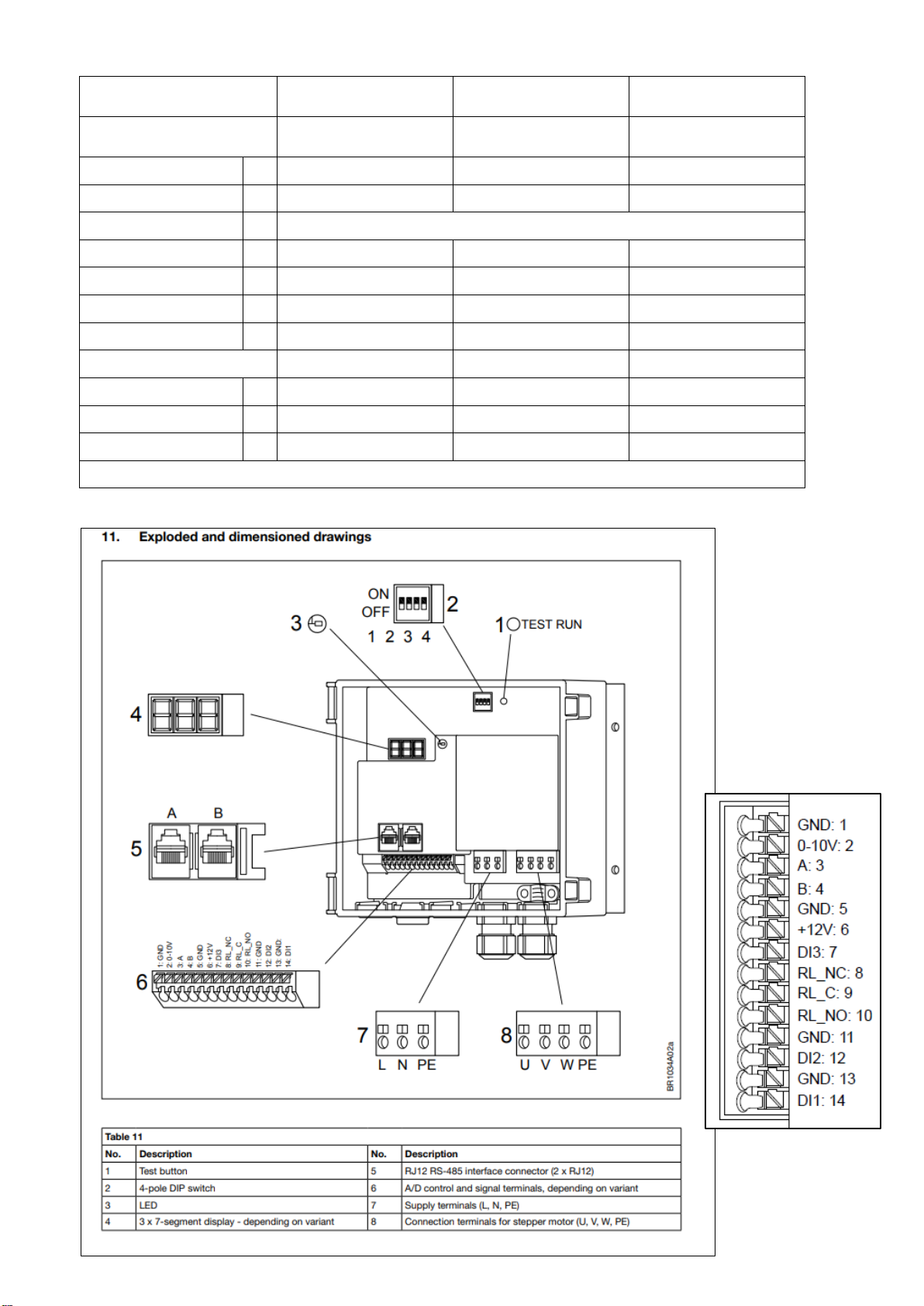

1

Manual OJ Electronics Stepper motor system

MRHX-2/-4/-8Nm & DRHX-1055, -1220

HO*-DRHX-1055/1220-MAD5

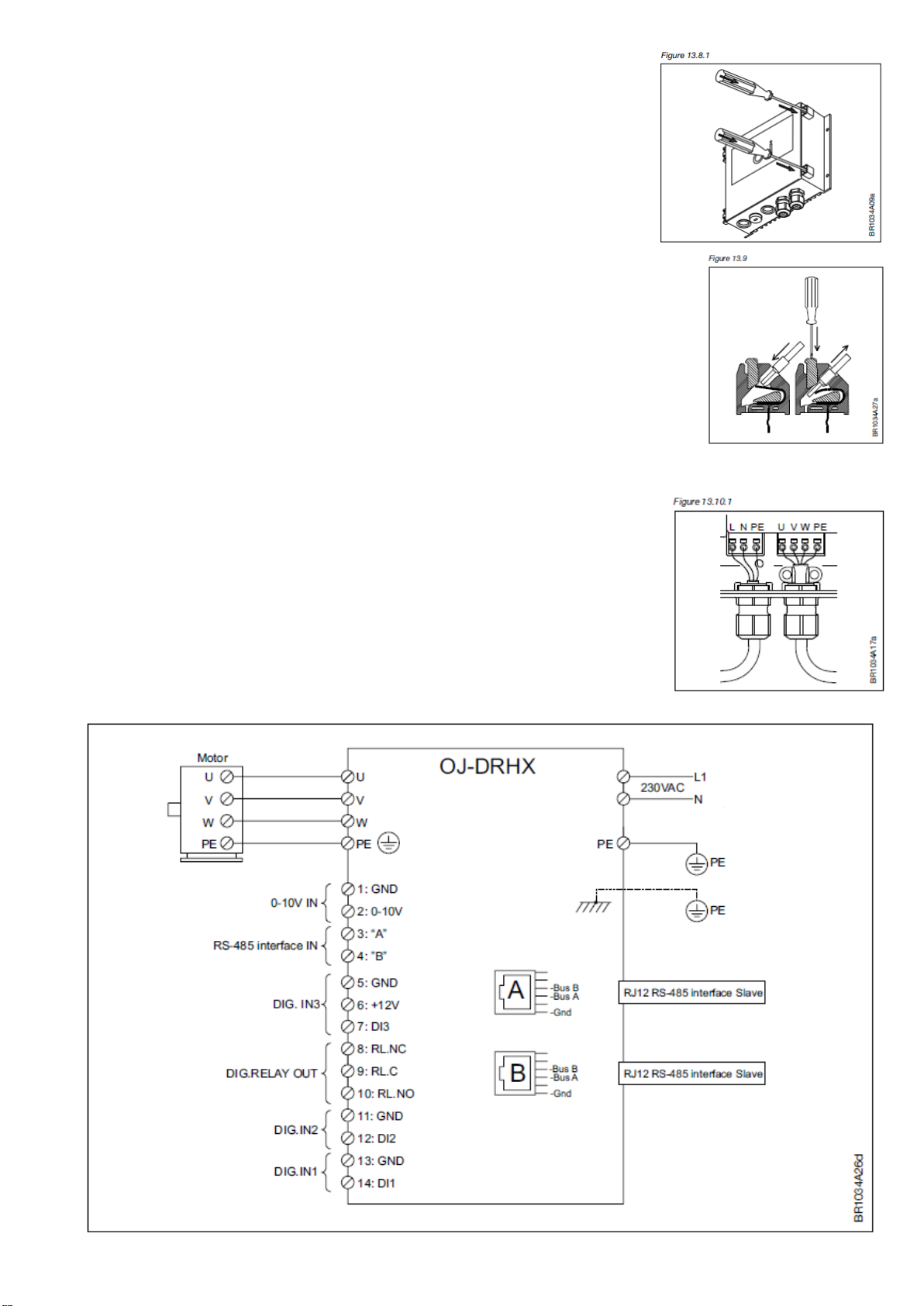

Hoval factory setting is for analogue use (0-10V)

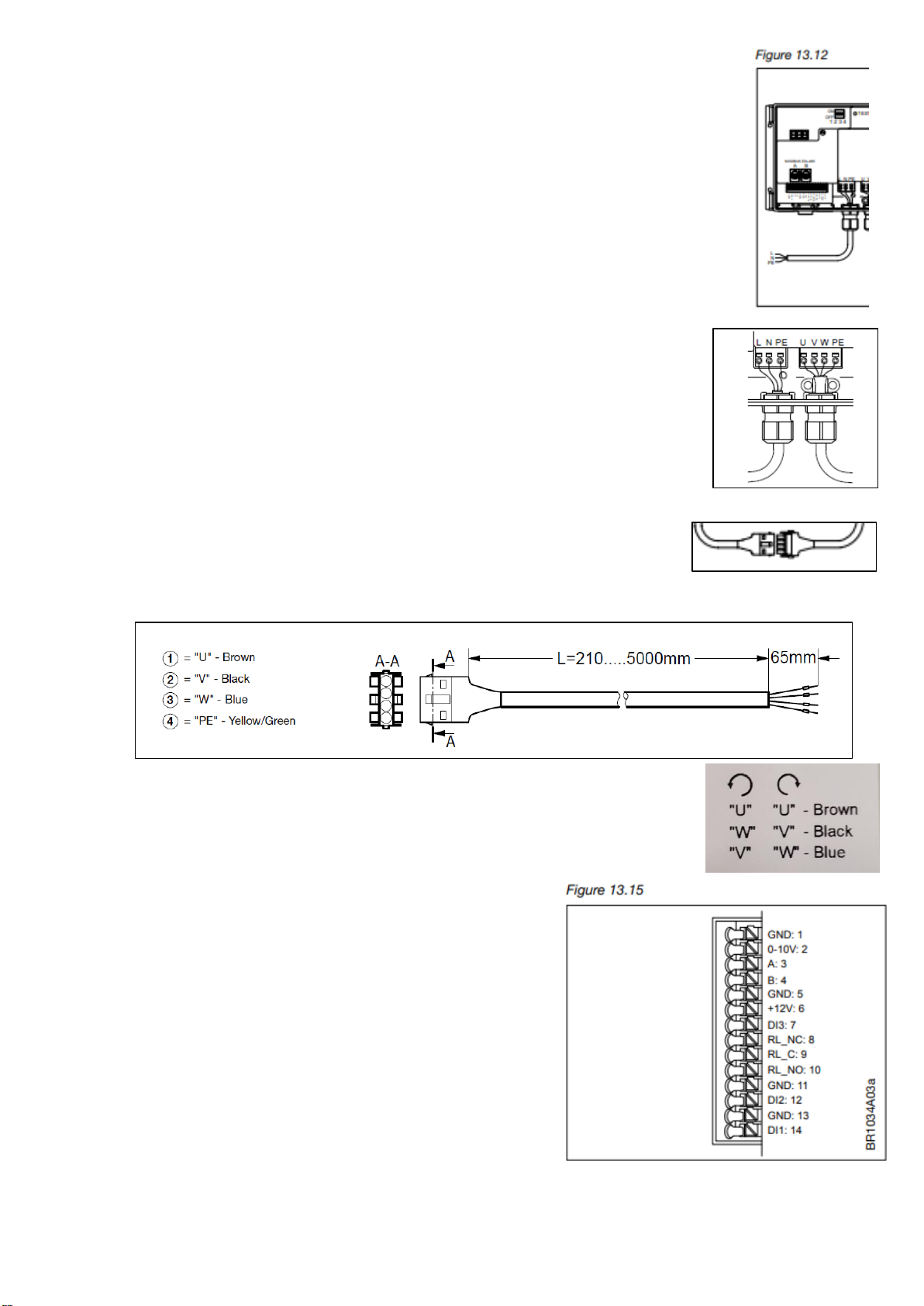

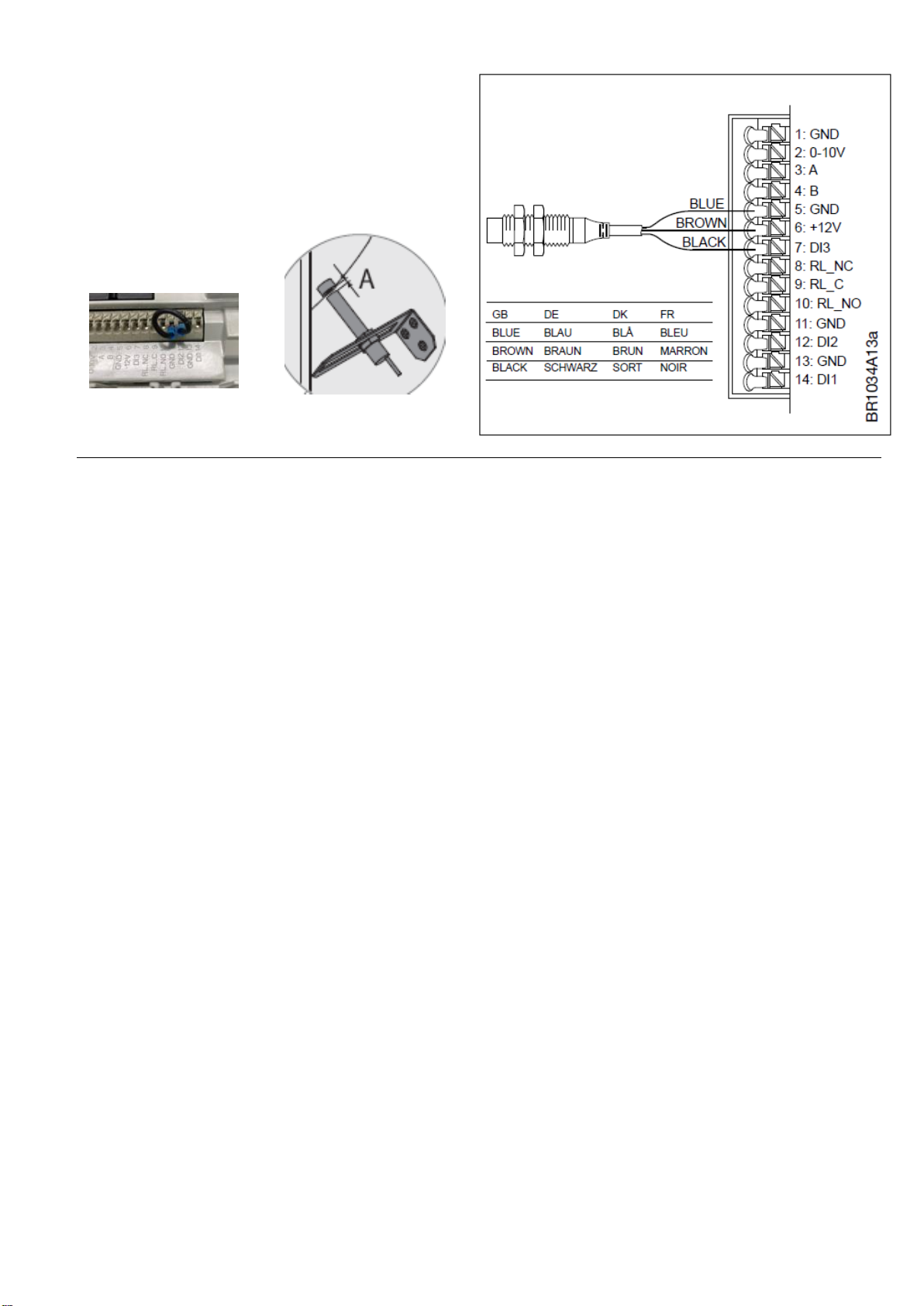

DI1: Rotor rotation

DI2: Enable external rotor guard

DI3: Signal from external rotor guard

MHRX = motor DRHX = control unit

*The DHRX control unit is programed with a Hoval custom made UDF file

This manual is specific for the setup of the Hoval drive system in RHE

For complete instructions, information, warnings (caution/ protection) see OJ's original manual.

Also valid for Modbus or OJ's DRHX PC –Tool (link and QR-code:

https://ojelectronics.com/hvac/products/oj-drhx-drives/

Introduction

MRHX/DRHX cannot be repaired on site. Never attempt to repair defective DRHX control unit or MHRX motor.

Contact Hoval for support.

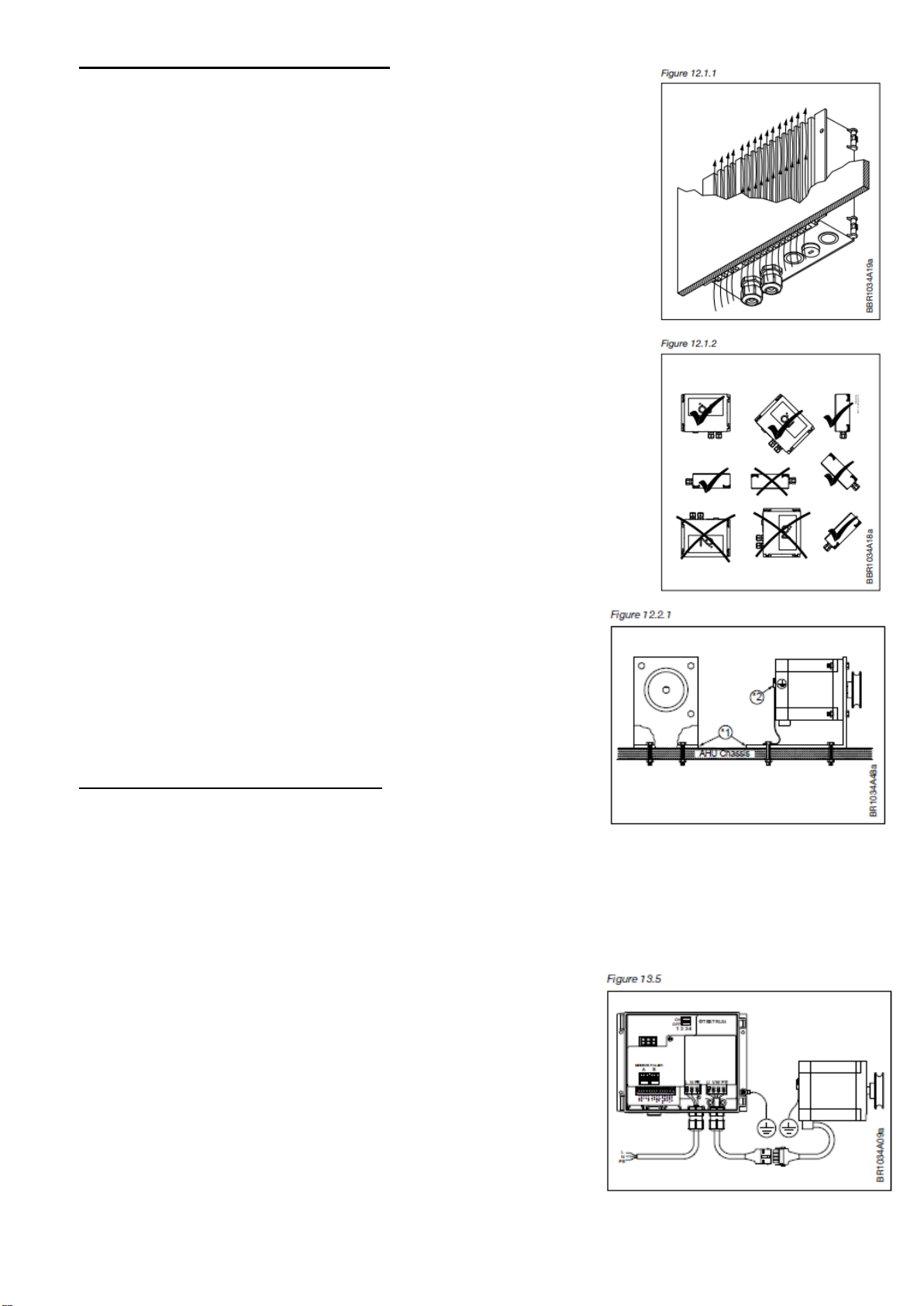

Ensuring safety before installation

Product MRHX/ DRHX must only be installed by qualified personnel or people who have received appropriate

training and have thus become qualified to install the product.

Controller DRHX contains dangerous high voltage when connected to the mains. Mains voltage must always be dis-

connected before any installation, service or maintenance tasks are performed on the product.

The test button can be operated while mains voltage is connected. The stepper motor/ rotor can be started up using

the test button, the 0–10 V input signal or via the RS-485 interface (Modbus).

Before connecting mains voltage to the DRHX controller

- all components, i.e. stepper motor, belt, pulley and rotor, must be installed correctly.

- all openings, covers and cable glands must be properly fitted and closed.

To maintain the specified enclosure rating, unused cable glands should be replaced with blank glands/ plug.

Controller DRHX contains capacitors which become charged during operation. These capacitors can remain

charged even after the power supply has been cut off. There is a risk of severe personal injury if the

connection terminals or wire ends are touched before these capacitors have been completely discharged.

The discharge time is about 3 minutes under normal conditions.

Product use

DRHX controller is used to regulate the speed of a rotary heat exchanger in air handling units. Controller DRHX can

only be used to control MRHX stepper motor, supplied by OJ Electronics A/S. Never try to connect or control other

types of stepper motor.

Technical specifications

The controller and stepper motor is controlled by signals or commands from an external control unit in the AHU.

DRHX controller has built-in stepper motor protection and has a built-in EMC filter.

The product carries a manufacturer's warranty if installed in accordance with these instructions and applicable

installation regulations. If the product has been damaged (e.g. during transportation), it must be checked and (if

necessary) repaired by OJ Electronics A/S before the product is installed, connected to mains voltage and

energized.

No 4220637 Ver 3 2020-12-17/ SESTCH

Contact