Adjustments

Spindle (19 and 48) End Play Adjustment

The spindles should have from l/ 32,, to l/16'rof

up and down movement. To adjust loosen set screw

(65) on spindle to be adjusted andmove the pulley (bb)

up or down as required until the correct end play is

obtained.

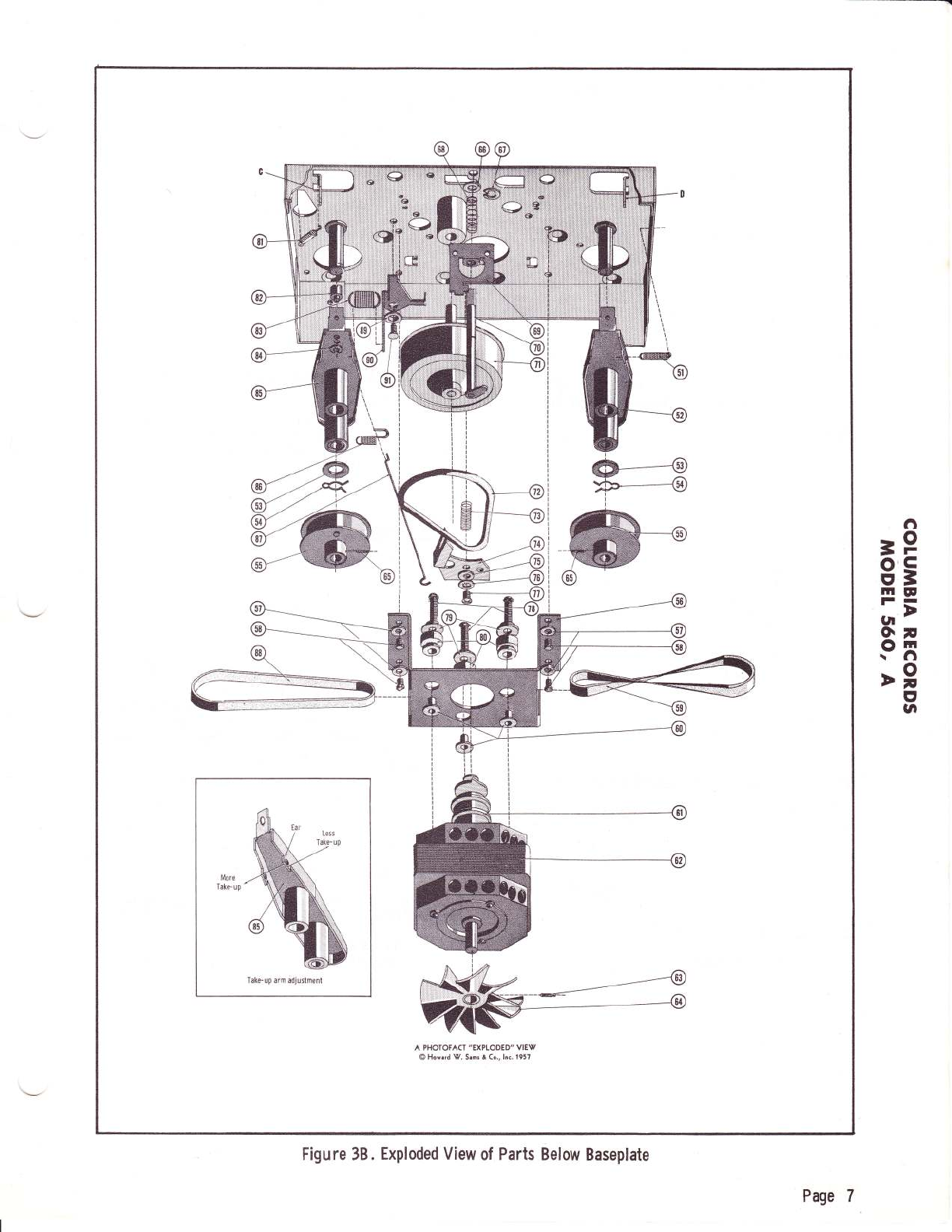

Take-Up Lever Adjustment

Spring (83) on take-up lever (90) controls the

timingof the left take-up reelholder (9). Withthe con-

trol knob (5) in the play back position, thetake-up reel

shouldstart revolvingat the sametime ora littleafter

the Pressure Roller (43) starts pulling the tape past

the head (39).

Check adjustment by placing a fully loaded ?',

reel on the take-up spindle. Rewind for about 10 se-

conds. Move the control knob (5) to the playback

position and observe the action described above.

If adjustment is required, bend ear on take-up

arm (85) iu the position and direction indicated in

sketch on exposed view. Caremustbeexercised when

making this adjustment and repeated trials between

bends should be made.

Take-Up And Feed Reel Drag

When the control knob (5) is placed in the INeu_

tral" position the reels should stop prompuy with a

minimum of overrun. Thereshould benoloopingof the

tape. With control knob (5) in the neutral position and

without reels on theholders, they mayrevolve slightly,

butonce the reels are put in place they should not re-

volve.

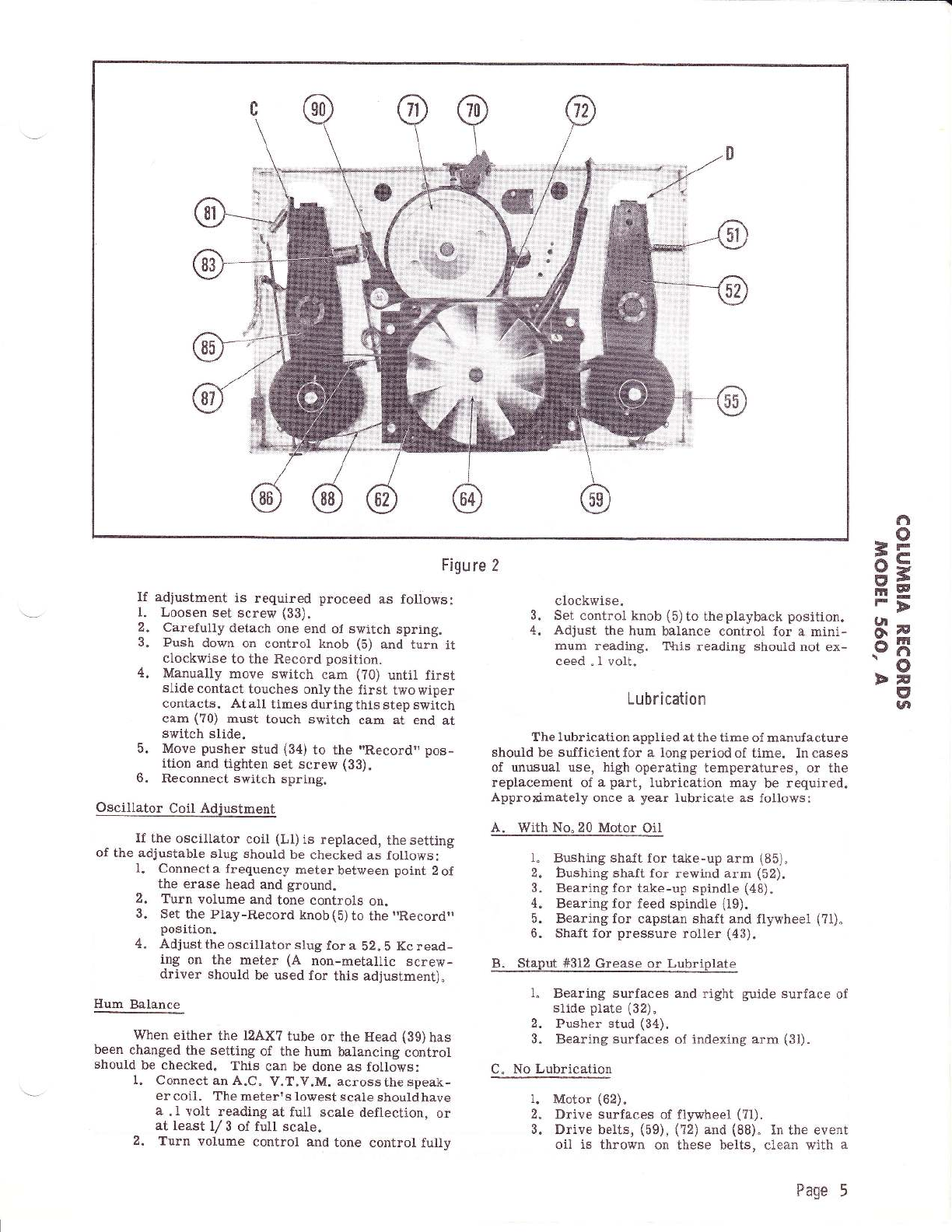

Stops, labeled "C" and 'T)" on figure 2, located

on base plate (22) controls the above action. Theyre-

gulate the amount of return that take-up arm (85) or

rewind arm (52) makes after controls have been re-

leasedl not sufficient return would cause continued

Fast Rewind or Fast Forward operation, while too

much return would not allow drive belts (88) or (59) to

put a drag on the respective pulleys. Bend these stops

carefully so as to obtain operation described above.

Stop "C"controls the take-up sidewhile stop tDrtcon-

trols the rewind side.

Head Alignment Adjustment

It is extremely important that the Head (39) be

lined up perfectly with the tape. If not the result will

probably be low output, track overlap, or loss of high

frequencies.

l. Model 560 (SHURE Head)

If the SHURE Head requires replacement the

complete assembly composed of the head and head

holder should be replaced" The head holder is adjusted

individuallvto thehead and sealedatthefactory. When

installing head ( 39A) observe the following precautions:

HEAD HEIGITT: Place a .l?9" gauge (between

11/64" and 3/16") near the mounting bracket and between

base plate (22) and bottom of head holder. Push down

on head (39A) and tighten set screw (23). Remove

gauge.

An alternate method ofadjusting the head height

when a gauge is not available follows:

Page 4

Remove the pressure shoe assembly (36)

from the pressure bracket so the head can

be observed through theopeningin thepres-

sure bracket"

Align head (39A) so the bottom of the head

opening is at the same level (or slightly high-

er) as the correspondingbottom of the open-

ing of the pressure bracket.

With the unit pulling tape, the tape should

approach the take-up reel nearly centered

between the flanges of the reel. If the tape

runs against the bottom flange it is an in-

dication that the head is too low.

Make "Output Response" adjustment as de-

scribed in Section 3 below.

2" Model 56OA /Michionn Mrqnctin F{cad\

On units using the Michigan Magnetic Head a

simpl.e alignment procedure is as follows:

a). Place a full reel of tape on the right hand

spindle(19) andthread tape. See "Threading

TaPe".

b). Pull tape tightagainst Heads (26) and(28) by

rotating one reel while holding the other reel.

c). Both heads should then be positioned so the

top edge of the tape is exactly even with the

bottom edge of the ground down 'tlat" section

on the face of the heads.

d). When in thisposition both heads shouldalso

be perpendicular to the bracket vertically

and horizontally.

e). The faces of the heads should be j.n line with

each other soas to present a flatsurface to

the tape, i. e. one head should not protrude

further forward than the other"

3. Output Besponse

To make this adjustment a tape on which a 3000

cycle note has been recorded by a unit known to be in

good operating condition will be required.

Connect an output meter, or AC voltmeter,

aeross the spealer voice coil of theunittobe adjusted.

While playingback the 3000cyclenote tape, pivot head

(39) back and forth on mounting screw (23) until maxi-

mum amplitude on output meter is achieved. Make

certain that head height has not been changed.

If a 3000 cycle tape cannot be make, use a re-

cording with hlgh note content to make the adjustment

described above.

4. Track Overlap

This should be checked by first making a re-

cording on a blank tape with the unit being checked.

Do notrewind thetape, merelyreverse thereels

and play back the other track.

There should be no sound but, if what is heard

isbackwards, there is trackoverlap. Tocorrect this,

it will be necessary to adjust the tape guide on the side

of the head holder by bending it upwards. This should

move the tracks further apart.

Switch Cam Adjustment

The Play-Record Switchin the amplifier chassis

is normally held inthe playpositionby aspringlocated

on the switch arm. Whencam onthe endof thecontrol

shaft (70) actuates switch, it should move the switch

far enough to allow all circuits to be switched from

Playback to Record.

a).

b).

c).

d).