2 Overview EN

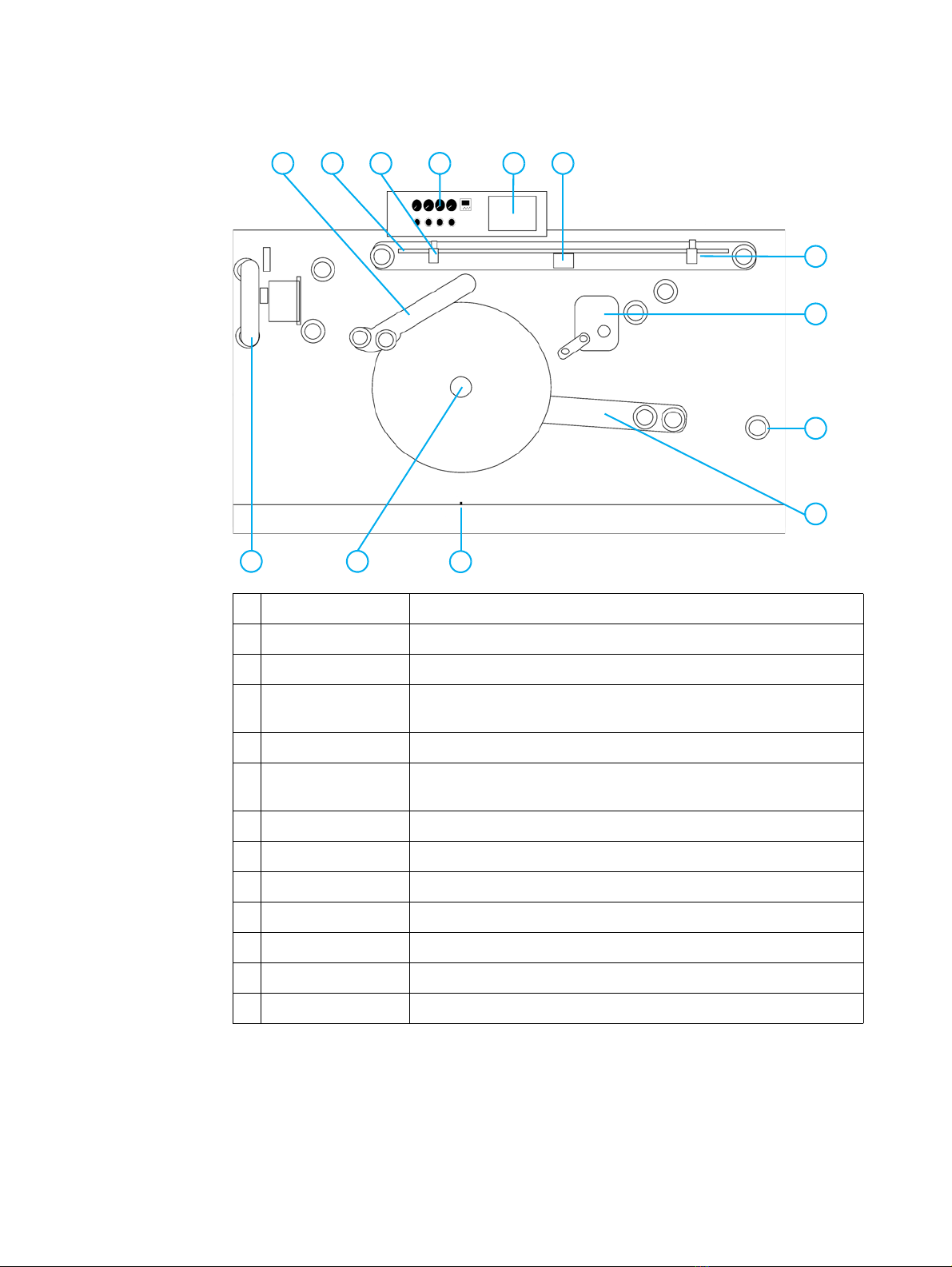

Overview

The flexible packaging rewinder is used to rewind the web.

The rewinder:

zSupports a wide variety of flexible packaging substrates and thin films that are less

than 50 µm thick

zPrevents wrinkles, telescoping, and ink back transferring

zCan rotate clockwise or counterclockwise

zEnables you to rewind the web with the print facing the inside or outside of the roll

zIs controlled from the touch screen

zConnects to the printing engine through an interface cable

zIncludes a web guide with a lateral rewinding accuracy of 0.3 mm

zIncludes a meter counter

Table 1-1 shows the rewinder specifications.

Table 1-1. Specifications

Parameter Specification

Power supply 230 VAC / 8 A / 1p+1n+GND

or

110 VAC / 15 A / 1p+1n+GND

Power consumption 1,650 W

Air supply 6 - 10 bar (maximum:10 liter/min)

Maximum web width 330 mm (13 in)

Maximum web roll diameter

(if you use a heavy substrate, the maximum web

roll weight may cause this value to decrease)

600 mm (26 in)

Maximum web roll weight

(when the rewinder is attached to the floor)

100 kg (220 lb)

Maximum web roll weight

(when the rewinder is not attached to the floor)

75 kg (165 lb)

Standard web core diameter 76 mm (3 in)

Rewinder height 1,280 mm (50 in)

Rewinder length 1,905 mm (75 in)

Rewinder width 960 mm (38 in)

Rewinder weight (including packaging) 500 kg (1,102 lb)