Page 4of 21

V. Before You Begin Installation

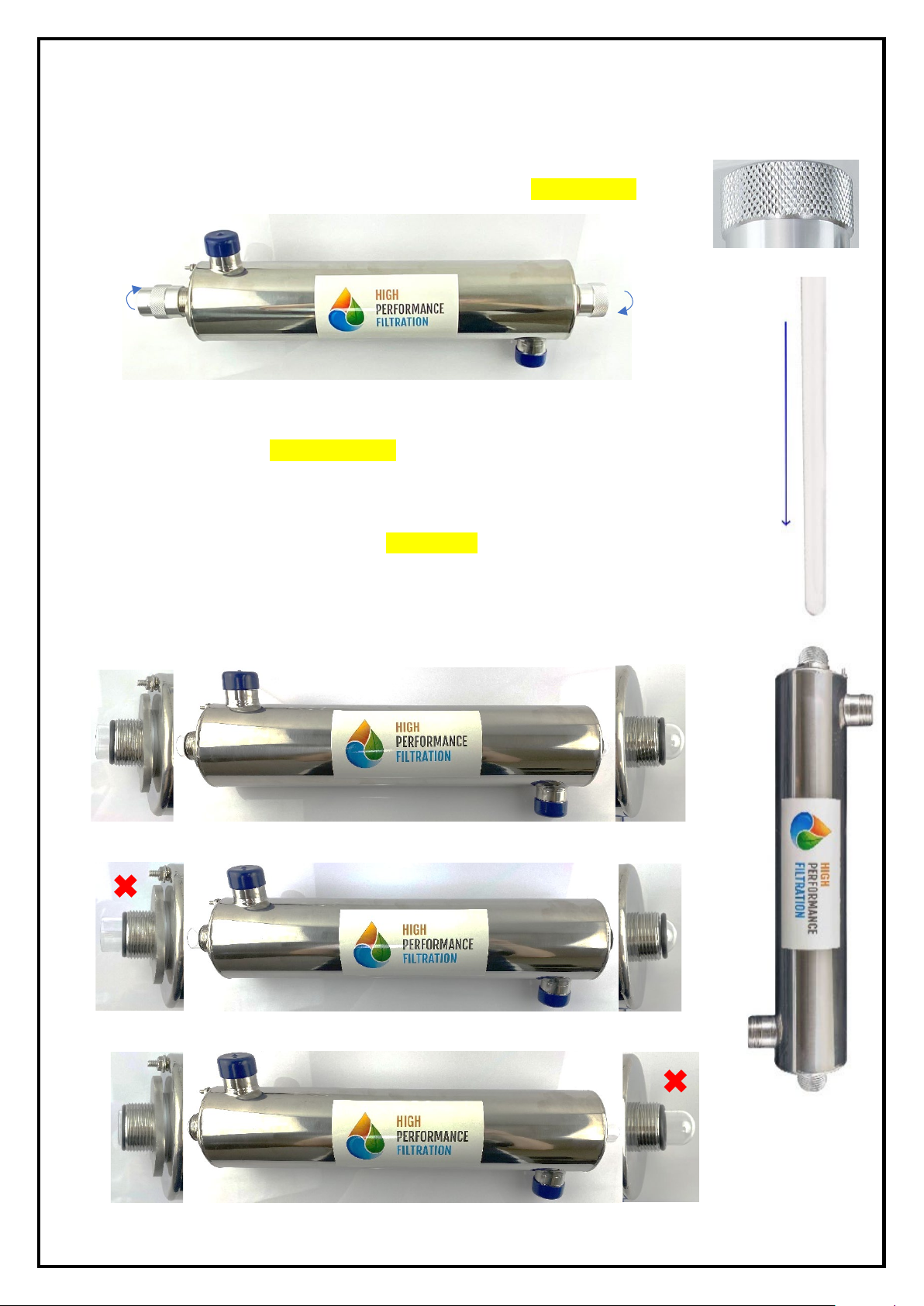

The HPF-UV systems come pre-assembled on the bracket with centre joiners installed. These units are batch tested to

ensure there are no leaks. Due to transit, fittings and other components may be loosened or damaged –

ensure the system is inspected for damages prior to employing a plumber for installation.

•To ensure full germicidal protection, tanks should be treated with HydroSil-ULTRA (Hydrogen Peroxide Water

Sanitiser) before the HPF-UV system is installed. After dosing, run water throughout the house (open each

tap) and this will sanitise the plumbing within your house. This is required as UV systems are a point of

contact sanitiser which do not have any residual effect (i.e., they only kill bacteria when flowing through the

UV; UV radiation does not stay in the water as is moves throughout your house). Once this is completed, you

can begin installation. The procedure for sanitising the plumbing system is readily accomplished as follows:

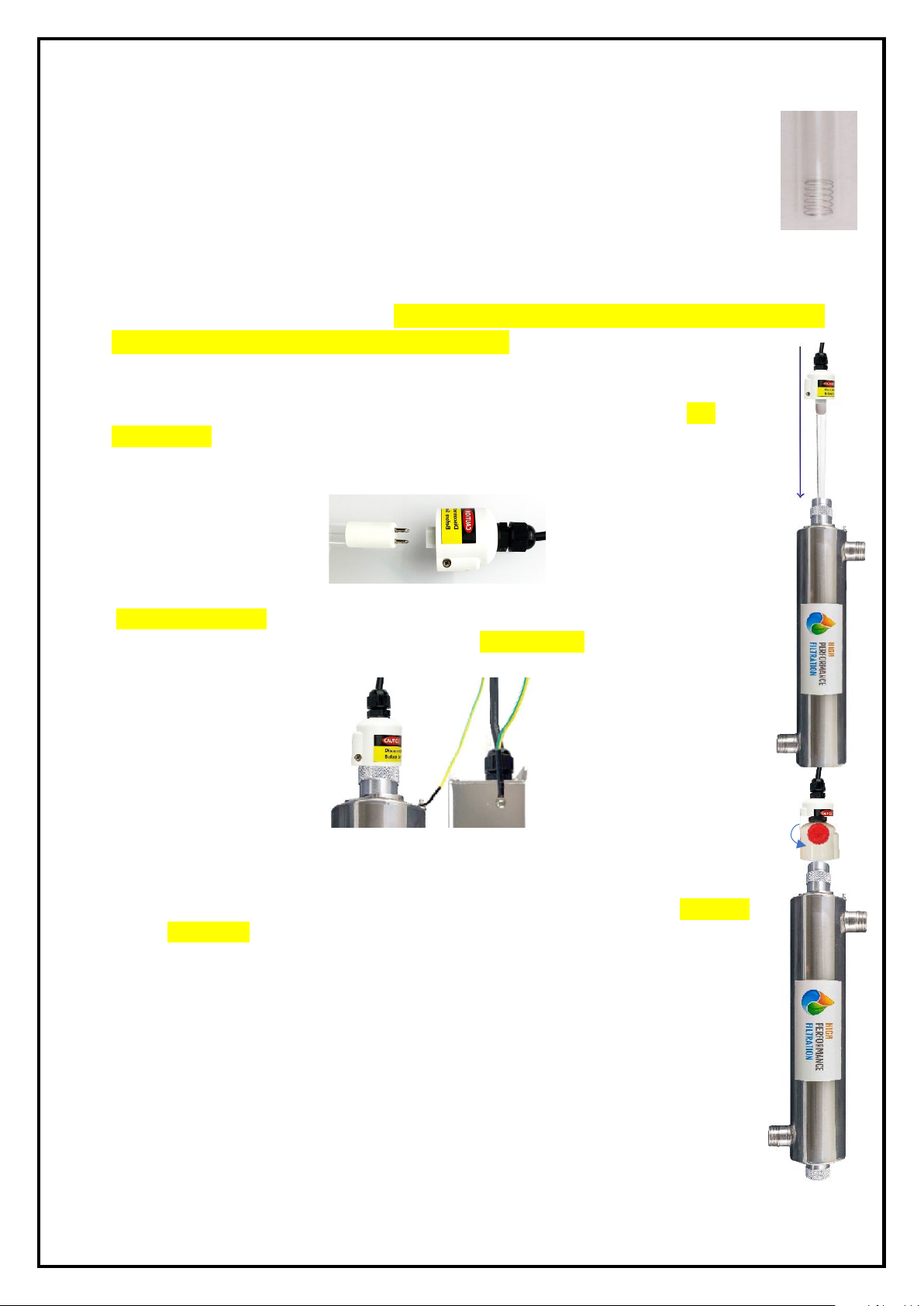

1. Shut off the upstream water supply that feeds water into the reactor chamber and depressurise

water system (if applicable).

2. Remove the pre-filter cartridge and add the recommended dosage of Hydrosil Ultra as per

manufacturer’s instructions. (Available at your local re sellers)

3. Verify that the UV System is connected to the AC power voltage and operating properly.

4. Open all faucets, fixtures and appliances and allow cold water to rununtil you are satisfied that the

Hydrosil has reached every outlet. Shut the faucets off and leave the solution sit for a period of 30-60

minutes. You must ensure that all taps, including outside faucets, dishwashers, shower heads,

washing machines, toilets, hot water heater, etc., andany device or appliance attached to the

plumbing system pass the treated water.

5. Open the upstream water supply and reinstall any filter cartridges (if applicable) into the filter and

then you can run the system as per instructions.

6. It is important to remember that in the event that a UV is briefly shut down for routine cleaning or

during power interruptions where water could have passed through the system, the aforementioned

pipe disinfection procedure must be conducted again.

•The UV system should be installed after a filter on the return line. This helps ensure that the water is clear of

debris and impurities that could inhibit the disinfection process and increase the risk of damage toglass

internals. The UV can be installed before a filter, however, it will take longer to work.

•If water pressure is above 12bar, add a PRESSURE REGULATING VALVE on the inlet side of the equipment to

protect the Thimble.

•If water demand can possibly exceed the rated flow, install a flow restrictor on the inlet side of the device.

VI. What is Standard Filtration

Standard Filtration generally refers to systems designed to remove dirt/sediment & chemicals (such as chlorine) from

drinking water. Standard Filtration and UV systems are NOT designed to remove Fluoride or other dissolved salts or

minerals from water. Such units are generally simple to install/run, have a low cost to maintain and help improve the

taste of the water whilst removing common impurities.

VII. Product Application: What is UV light and How Does It Work?

UV water disinfection systems are a popular, highly effective, and easy to use way to protect your family from water-

borne living organisms. It is trusted by thousands of people worldwide and is widely used in homes, offices,

commercial and industrial applications.

Advantages of UV include:

•Effectiveness: Application of UV light triggers a reaction almost instantly; more effective than chlorination and other

water disinfection systems on a wide range of pathogens.

•Safe and chemical-free: UV light does not result in the creation of harmful disinfection by-products; UV does not alter

water chemistry and its constituents, such as pH, taste, odour, colour etc.

•Low Cost: Capital cost is low and operating cost is low compared to alternative disinfection methods.

•Simple to install and operate: no moving parts to wear out; installation flexibility.