Content

Part 1 –Safety & Warning...................................................................................................................1

Part 2 –Product Introduction............................................................................................................. 2

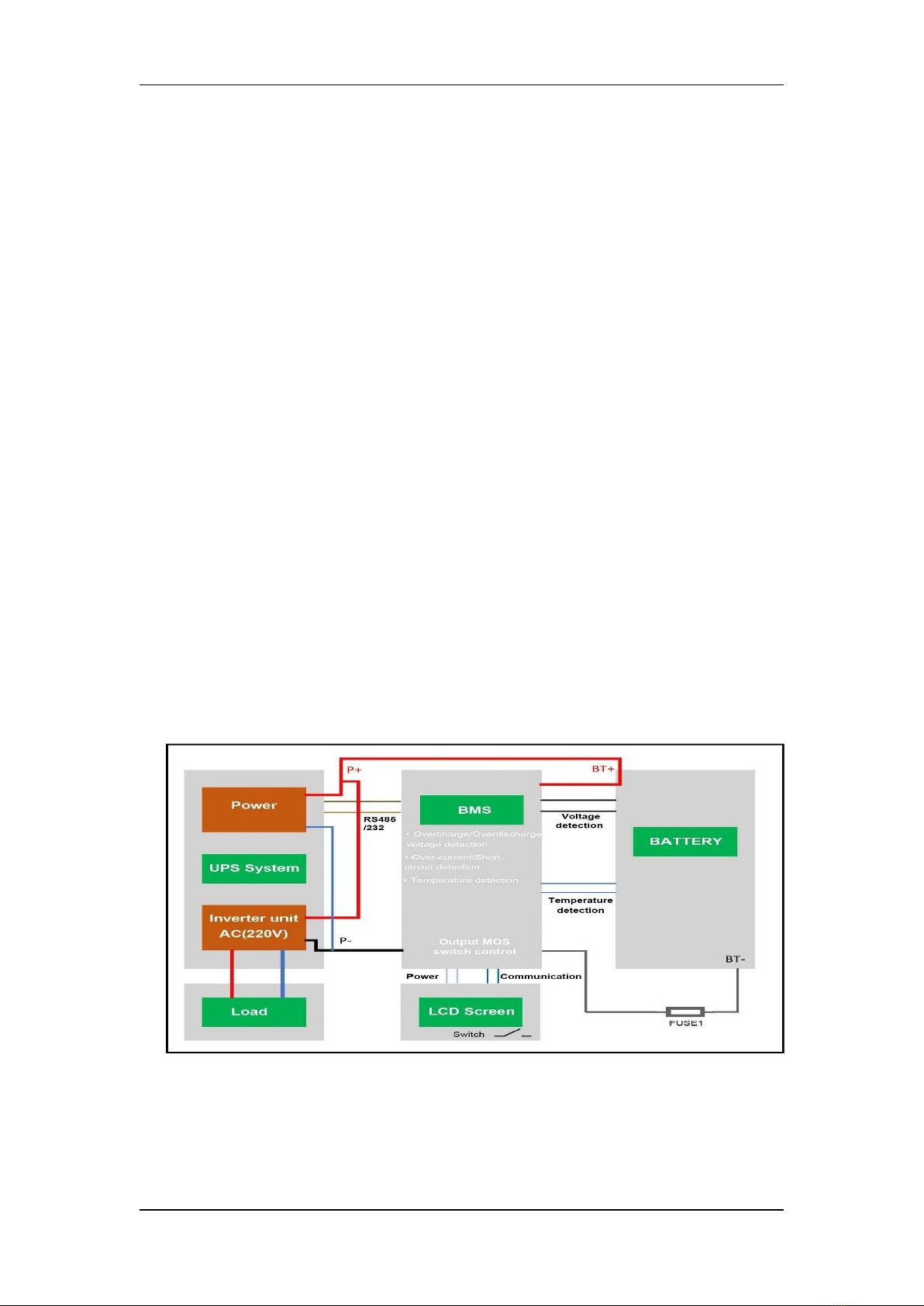

2.1 –Overview.............................................................................................................................2

2.2 –Working Principle............................................................................................................... 2

2.3–Applications.........................................................................................................................2

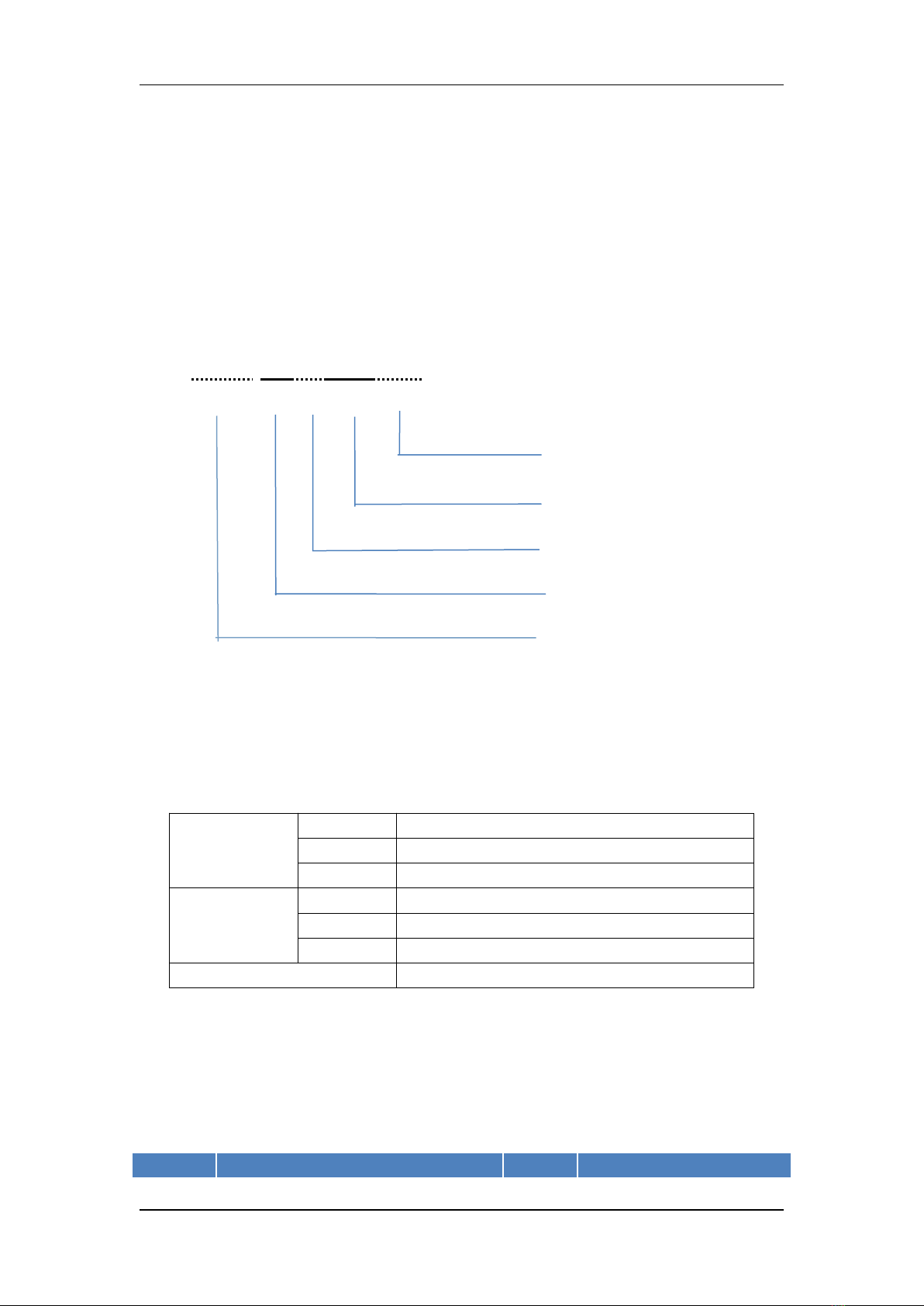

2.5–Battery Model Name...........................................................................................................3

Part 4 –Operation & Maintenance.....................................................................................................3

4.1 –Requirements for Operation Environment........................................................................ 3

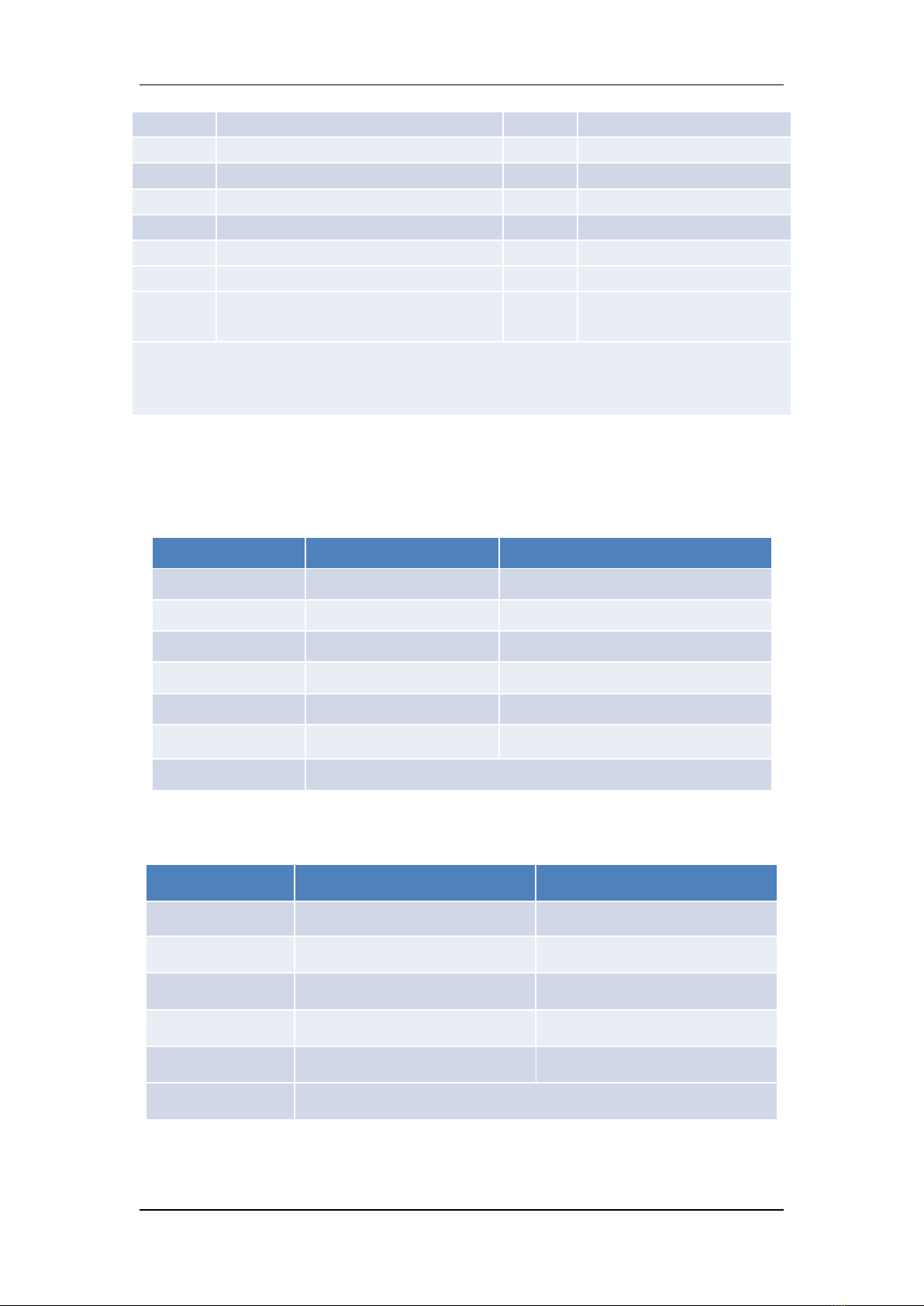

4.2 –Parameter Settings of Power Plant.................................................................................... 3

4.3 –Charge/Discharge Modes and Conditions......................................................................... 4

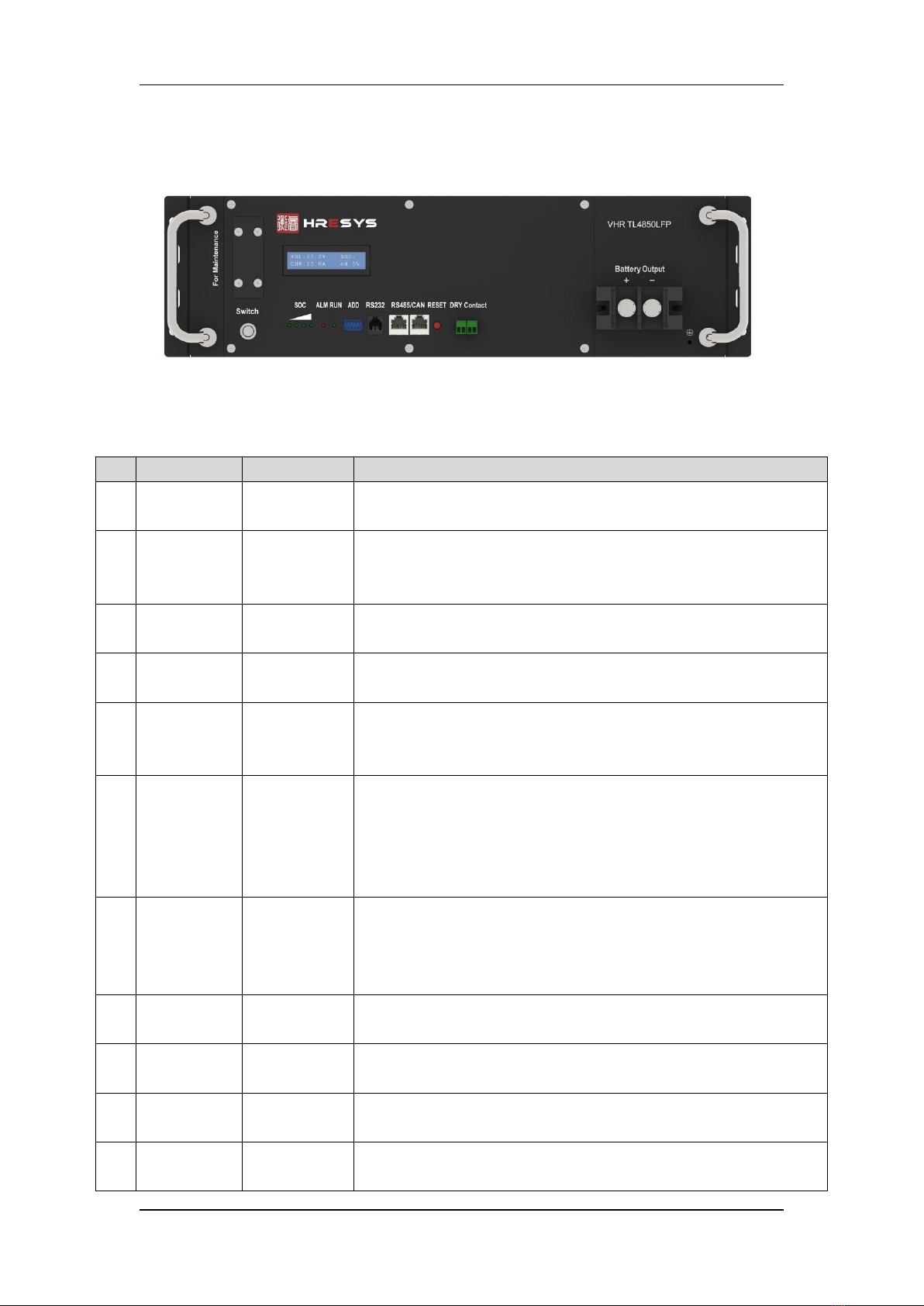

4.4 –Layout of Front Panel......................................................................................................... 5

4.5 - Shipment............................................................................................................................. 6

4.6 – Installation..........................................................................................................................6

Unboxing & Inspection........................................................................................................6

Preparation for Installation.................................................................................................6

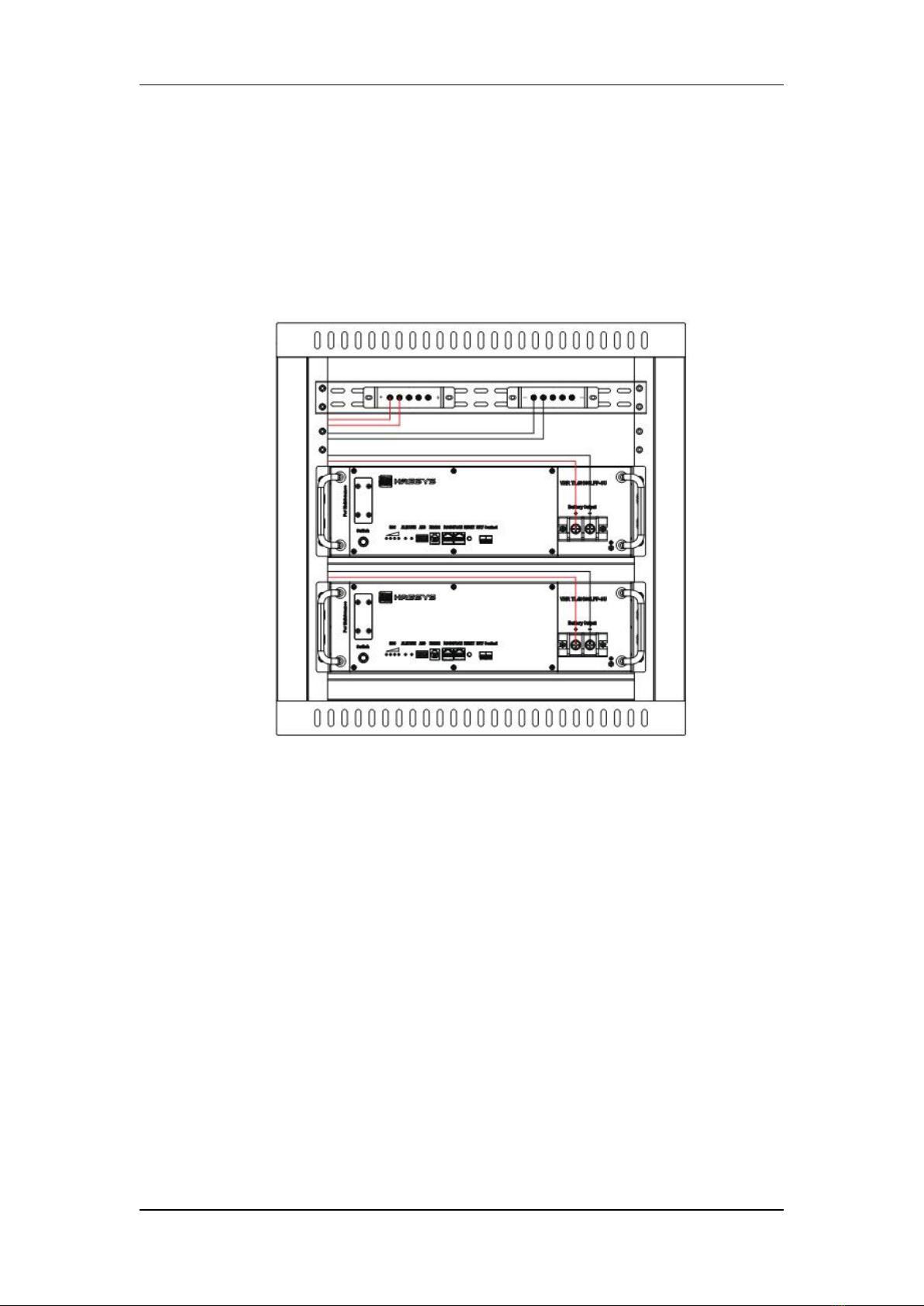

Installation of Battery Modules.......................................................................................... 7

4.7 – Storage................................................................................................................................9

4.7.1 Storage Requirements................................................................................................9

4.7.2 Judgement Conditions for Overdue Storage............................................................. 9

4.7.3 Recharge process..................................................................................................... 10

4.8 – Maintenance..................................................................................................................... 10

Part 5 –Troubleshooting & Solutions............................................................................................... 11

Annex 1 –Instructions for LED Flicker...............................................................................................12

Annex 2 –Instructions for ADD Dialing.............................................................................................13

Annex 3 –Communication Protocol for RS232 and RS485.............................................................. 14