For advice on the safety and suitability of this

equipment contact your local HSS Hire.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed prior

to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by his/her

employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from the

work area. Cordon off a NO GO area using cones and

either barriers or tape, available for hire from your local

HSS Hire.

Never use this equipment if you are ill, feeling

tired, or under the influence of alcohol or

drugs.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by everyone

in the vicinity.

Wear practical, protective clothing, gloves

and footwear. Avoid loose garments and

jewellery that could catch in moving parts, tie back long

hair.

Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment at

your local HSS Hire.

Make sure you know how to switch this machine OFF

before you switch it ON in case you get into difficulty.

Always switch the engine off and wait for moving parts to

come to rest before making adjustments to it.

Engines, especially the exhausts, get very hot so switch

OFF and allow to cool before touching them.

Keep flammable materials well away from engine and

exhaust.

Survey the area to be dug and ensure that there are NO

hidden services (electric cables, soil pipes etc) below

the work area. If in doubt, use a cable-avoiding tool

available from your local HSS Hire.

Be careful if your view is obstructed, avoid using the

machine under low branches where you are forced to

Exhaust Danger

NEVER operate petrol engines indoors or in a

confined space.

The exhaust contains gases that can kill.

GENERAL SAFETY

crouch to pass under.

The digging tines can cause serious injury. Always keep

feet and hands well away from the tines taking special

care when starting.

Make sure that anyone in the immediate work area is

warned of what you are doing.

Check the condition of the equipment before use. If it

shows signs of damage or excessive wear, return it to your

local HSS Hire.

Ensure the guard is correctly fitted and secure before

starting work.

Clear the area to be cultivated of everything that could

get in the machines way – sticks, stones, washing lines

etc.

Any long grass should be cut and cleared, as this will

clog the tines and reduce the depth of the dig.

Ensure the soil is in a suitable condition to be dug, soil

should be neither too wet nor too dry.

Adjust the rear depth bar to suite the depth you

require, this is held in position with an ‘R’ clip & pin. The

higher the bar the deeper the dig.

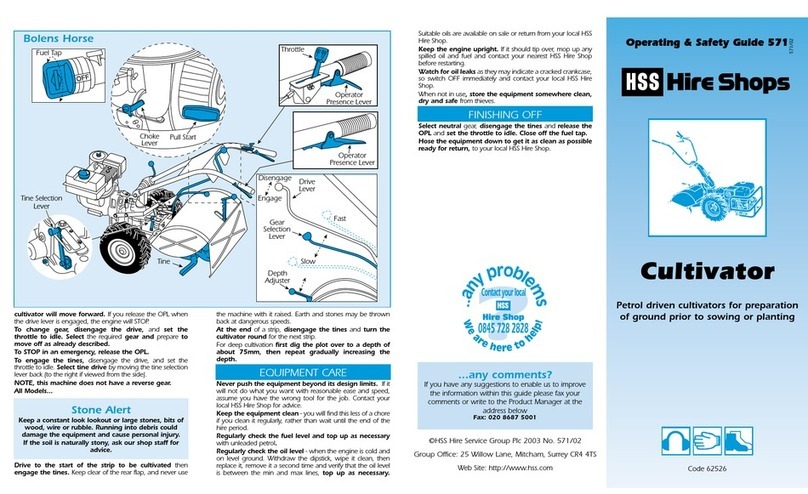

It is essential to familiarise yourself with all the controls

before starting.

With the machine on firm level ground, check fuel and

oil levels (see EQUIPMENT CARE).

Set the ON/OFF switch, located on the right hand

control handle, to the‘I’(ON) position. If at any time you

get into difficulty, move the switch to the ‘0’ (OFF)

position to stop the engine.

Open the breather valve (fitted to the fuel cap) three

full turns anticlockwise. If the breather valve is not

opened, the engine will be starved of fuel. However,

the valve must always be closed when the machine is

not in use. Open the fuel tap by turning quarter turn

anticlockwise and set the choke – fully closed if starting

from cold, half closed if the engine is warm.

The engine is fitted with an automatic clutch, which

engages the tines as the engine speed increases. It is

possible that the tines may turn when starting the

GETTING STARTED

engine, so make sure you grip the control handle firmly

when starting the engine.

Two or three brisk pulls on the starter cord should now

start the engine.

Once the engine has warmed up, fully open the choke

and switch the engine OFF.

To engage the tines, squeeze the throttle lever on the

right hand control handle. To stop the tines rotating

and set the engine to idle, simply release the throttle.

When digging a strip of earth, tilt the machine forward

while holding it back (it will try to run over the surface)

until it begins to cut into the soil, then allow it to

progress at its own rate until the strip is complete.

If the unit becomes stuck in one position, tilt it back to

allow it to progress.

At the end of the strip release the throttle and turn the

machine round ready for the next run.

Repeat the process until the entire area has been dug.

To stop in an emergency simply release the throttle

lever.

Stone Alert

Keep a lookout for bricks, large stones, bits of wood,

wire etc.

Running into debris could cause serious damage to

the digger.

BASIC TECHNIQUES

Fuel Safety

NEVER refuel while the engine is hot or running.

Never smoke or allow naked lights into the area

while refuelling.

Never inhale fuel vapour.

ALWAYS mop up any spillage as quickly as possible,

and change your clothes if you get fuel on yourself.

ALWAYS store fuel in a purpose-made sealed

container, in a cool, safe place well away from the

work area.