Installation Manual 3000B Page 8 of 9 May 2012

PARTS LIST

HUDSON PRODUCTS CORPORATION

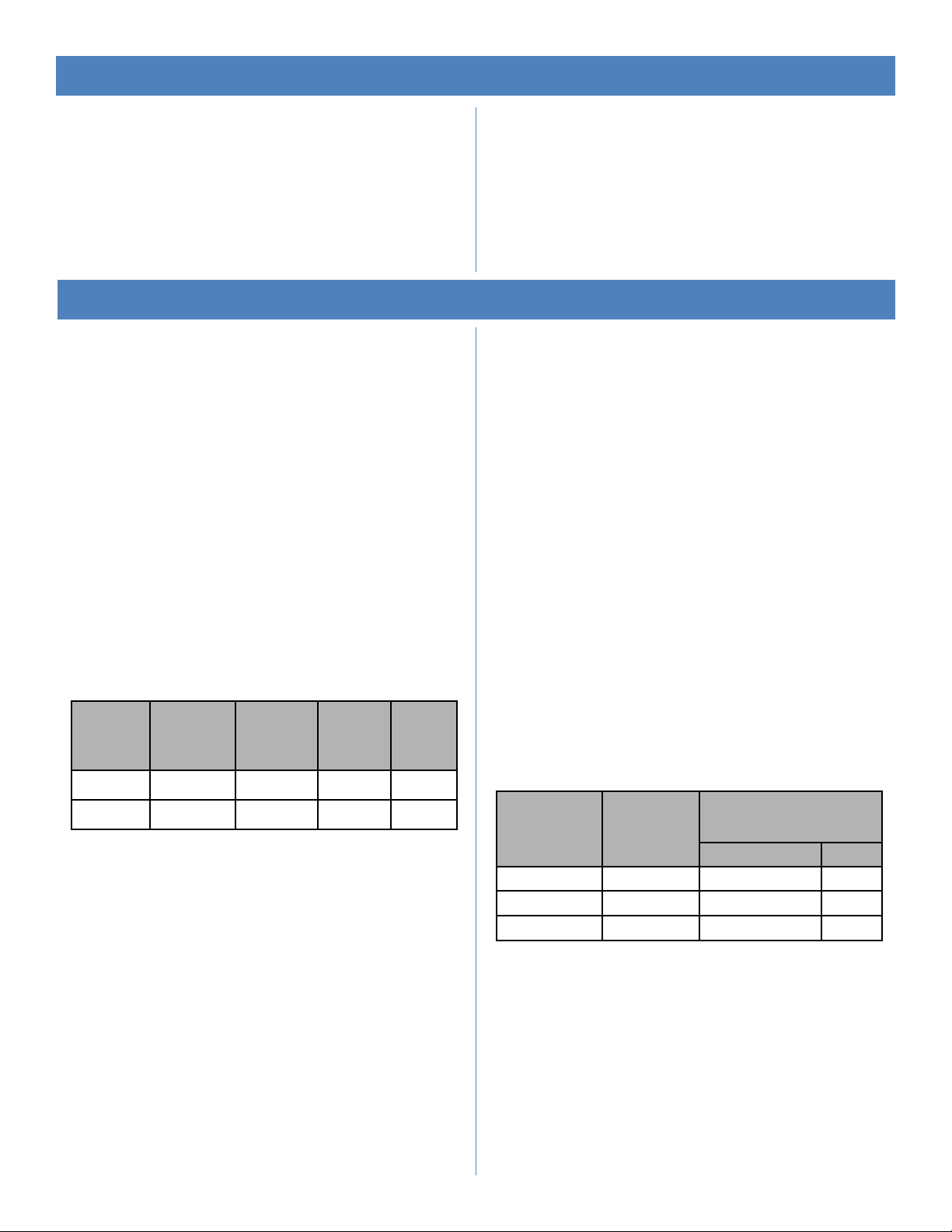

Adjustable Pitch Fan Assembly 5’ Thru 16’ Diameter

Series 3000B, C, D & W HUB

NO. OF BLADES

ITEM DESCRIPTION TYPE PART NO. 456

1” Dia. Thru 2.62 Dia Q-2Hub Assy. No.

Part No.

3104

H3100

3105

H3150

3106

H3110

2.68 Dia Thru 3.62 Dia R-2Hub Assy. No.

Part No.

3204

H3200

3205

H3250

3206

H3210

1Hub Body ***

(1 Per Hub)

Q-2Part No 65100 65106 65110

R-2Part No 65105 65108 65115

ITEM DESCRIPTION TYPE PART NO. QTY PER ASSEMBLY

2Bushing Q-2Specify Bore 111

R-2Specify Bore 111

3Blade Retainer Half 62380 810 12

4Lock Screw (#8-32 X 5/8) 72661 810 12

5Blade Socket Cap Screw (3/8 X 1-1/2), 316 SS 60274 16 20 24

63/8 Jam Nut, 316 SS 72051 16 20 24

7Cap Screw (3/8 X 5/8), 316 SS 72330 453

83/8 Lock Washer, 316 SS 73722 453

93/8 Flat Washer, 316 SS 73623 453

10

30” Dia Seal Disc (6’-10’ Dia Fans, 6B-10B Blades) 81100 111

38” Dia Seal Disc (6’-12’ Dia Fans, 6C-10C, 6D-10D & 11B-12B Blades) 81105 111

42” Dia Seal Disc (11’-14’ Dia Fans, 11W-12W & 13B-14B Blades) 81110 111

53” Dia Seal Disc (13’-16’ Dia Fans, 13W-16W Blades) 81114 111

11A

OR

11B

Old Style Severe Duty Blade Retainer Assembly Consisting of **

(1) - Severe Duty Blade Retainer (P/N 65289)

(2) - Cap Screws 3/8-16x2, 316 SS (P/N 53622)

(2) - Lock Washers 3/8,316 SS (P/N 73722)

(1) - Blade Retainer Spacer (P/N B3246)

K2200

456

New Style Severe Duty Blade Retainer Assembly Consisting of **

(1) - Severe Duty Blade Retainer (P/N D3261)

(2) - Cap Screws 3/8-16x2 1/4, 316 SS (P/N 69934)

(2) - Lock Washers 3/8, 316 SS (P/N 73722)

K2202

12 Retainer Ring Removal Tool 62379 111

13 Tuf-Lite® Blade (Black) (Varies) 456

STANDARD MATERIALS & FINISHES

WHEN ORDERING, SPECIFY FAN DIAMETER, TYPE & NUMBER OF BLADES & SHAFT DIAMETER

Blades: Fiberglass reinforced epoxy

Hub Body: Cast Iron, Enamel Finish

Fasteners: 316 Stainless Steel

Seal Disc: Fiberglass Reinforced Polyester

Bushing: Malleable Iron

Fasteners: 316 Stainless Steel

Fan Model Fan Diameter & Blade Type Number of Blades Shaft diameter

Adjustable Pitch (Specify “B”, “C”, “D” & “W”

for Tuf-Lite® Blades)

1 4B

EXAMPLE: APT 62 7/8” BORE

2

1

3

456

7

89

10

11B

HUB MODEL NO.

& SERIAL NO.

BLADE MODEL NO.

SERIAL NO.

KEY, SET SCREW & CAP SCREWS

FURNISHED WITH BUSHING

13

11A

OLD STYLE HUB

& RETRO-FIT

SDR SHOWN

NEW STYLE HUB

& SDR SHOWN

1

2

3

4

5

6

7

8

9

10

BUSHING

Q-2

R-2

Q-2

R-2

ITEM DESCRIPTION TYPE P/N

SPECIFY

BORE

1" DIA. THRU 2.62 DIA.

2.68 DIA. THRU 3.62 DIA.

Q-2

R-2

HUB ASSY. NO.

HUB ASSY. NO.

P/N

P/N

4 5 6ITEM DESCRIPTION TYPE P/N

NO. OF BLADES

PARTS LIST

HUB BODY

(1 PER HUB)

65100

65105

65106

65108

65110

65115

P/N

P/N

1

1

1

1

1

1

BLADE RETAINER HALF

LOCK SCREW (#8-32 x 5/8)

BLADE SOCKET CAP SCREW (3/8 x 1 1/2)

3/8 JAM NUT

CAP SCREW (3/8 x 5/8)

3/8 LOCK WASHER

3/8 FLAT WASHER

30" DIA SEAL DISC KIT (6'-10' DIA FANS, 6B-10B BLADES)

62380

72661

60274

72051

72330

73722

73623

3104

H3100

3105

H3150

3106

H3110

3204

H3200

3205

H3250

3206

H3210

810 12

810 12

16 20 24

16 20 24

4 3 3

4 3 3

4 3 3

1 1 1

4 5 6

NOT SOLD SEPARATELY.

OPTIONAL, BUT STANDARD WITH "W" BLADES

QTY. PER ASSEMBLY

12 RETAINER RING REMOVAL TOOL 62379 1 1 1

81100

INCLUDES ALL HARDWARE (316 SS) TO ASSEMBLE & MOUNT

TUF-LITE BLADE (BLACK)

R(VARIES)

13 4 5 6

38" DIA SEAL DISC KIT (6'-12' DIA FANS, 6C-10C, 6D-10D & 11B-12B BLADES)

53" DIA SEAL DISC KIT (13'-16' DIA FANS, 13W-16W BLADES)

81105

81114

42" DIA SEAL DISC KIT (11'-14' DIA FANS, 11W-12W & 13B-14B BLADES) 81110

11A K2200

OLD STYLE SEVERE DUTY BLADE RETAINER ASSEMBLY CONSISTING OF:

1 - SEVERE DUTY BLADE RETAINER (P/N 65289)

2 - CAP SCREWS 3/8-16x2 (P/N 53622)

1 - BLADE RETAINER SPACER (P/N B3246)

1 - SEVERE DUTY BLADE RETAINER (P/N D3261)

2 - CAP SCREWS 3/8-16x2 1/4 (P/N 69934)

2 - LOCK WASHERS 3/8 (P/N 73222)

2 - LOCK WASHERS 3/8 (P/N 73222)

NEW STYLE SEVERE DUTY BLADE RETAINER ASSEMBLY CONSISTING OF: K2202

11B

OR

**Optional, but standard with “W” blades

*** Not sold separately