HP 10 PUMP USER’S MANUAL

Page8

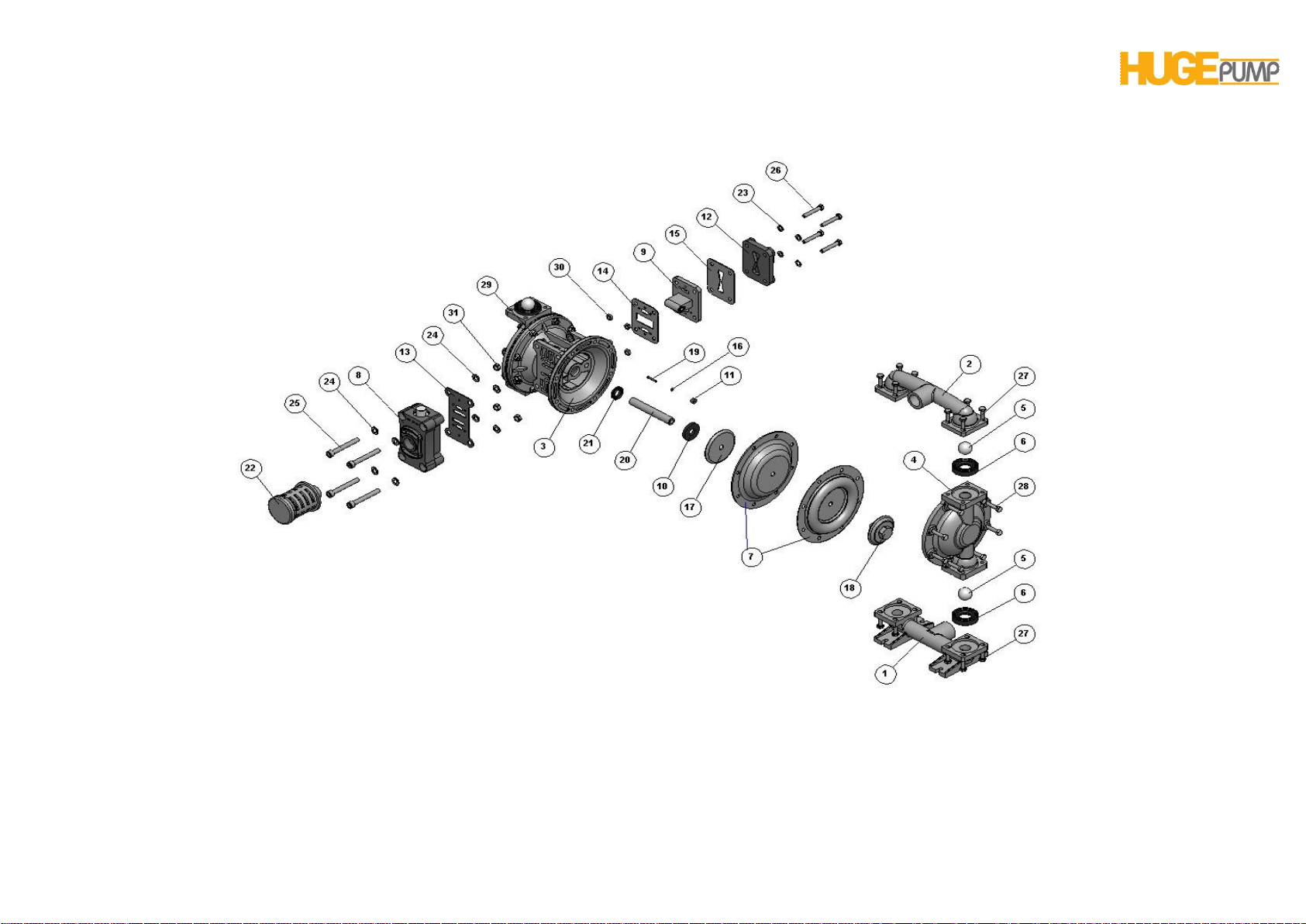

METALLIC PUMP COMPOSITE PARTS LIST

1S011030 Suction Line 1

S011031 Suction Line 1

S011032 Suction Line 1

2S021030 Discharge Line 1

S021031 Discharge Line 1

S021032 Discharge Line 1

3H011033 Main Body 1

4S031030 Outer Chamber 2

S031031 Outer Chamber 2

S031032 Outer Chamber 2

5S041045 Check Ball 4

S041046 Check Ball 4

S041047 Check Ball 4

S041048 Check Ball 4

S041050 Check Ball 4

S041051 Check Ball 4

6S051036 Check Ball Seat 4

S051045 Check Ball Seat 4

S051046 Check Ball Seat 4

S051047 Check Ball Seat 4

S051048 Check Ball Seat 4

S051050 Check Ball Seat 4

S051051 Check Ball Seat 4

7S061045 Diaphragm 2

S061046 Diaphragm 2

S061047 Diaphragm 2

S061048 Diaphragm 2

S061050 Diaphragm 2

S061051 Diaphragm 2

8H034033 Air Valve Repair Kit 1

9H044033 Pilot Valve Repair Kit 1

10 H051047 Bumper 2

11 H061036 Pin Bushing 2

12 H071033 Cover, Air Inlet Assembly 1

13 H084047 Gasket, Air Valve 1

14 H091047 Gasket, Pilot Valve, Front 1

15 H104047 Gasket, Pilot Valve, Rear 1

16 H124047 O-ring, Pin 2

17 H131030 Inner Diaphragm Holder 2

18 S071032 OuterDiaphragm Holder 2

S071033 OuterDiaphragm Holder 2

19 H141090 Actuator Pin 2

20 H151090 Diaphragm Rod 1

21 H161047 Oil Seal 2

22 H174036 Muffler 1

23 PM8-P Washer, M8 4

PM8 Washer, M8 4

24 PM10-P Washer, M10 8

PM10 Washer, M10 8

25 CM10X80-Pİ Capscrew M 10 X 80 (imbus)4

CM10X80 CapscrewM 10 X 80 (imbus)4

26 CM8X50-P CapscrewM 8 X 50 4

CM8X50 CapscrewM 8 X 50 4

27 CM8X25-P CapscrewM 8 X 25 16

CM8X25 CapscrewM 8 X 25 16

28 CM8X45-P CapscrewM 8 X 45 16

CM8X45 CapscrewM 8 X 45 16

29 SM8-PF Ring Nut, M8, Flanged 16

SM8-F Ring Nut, M8, Flanged 16