version 1.2_en page 5

Operating the instrument

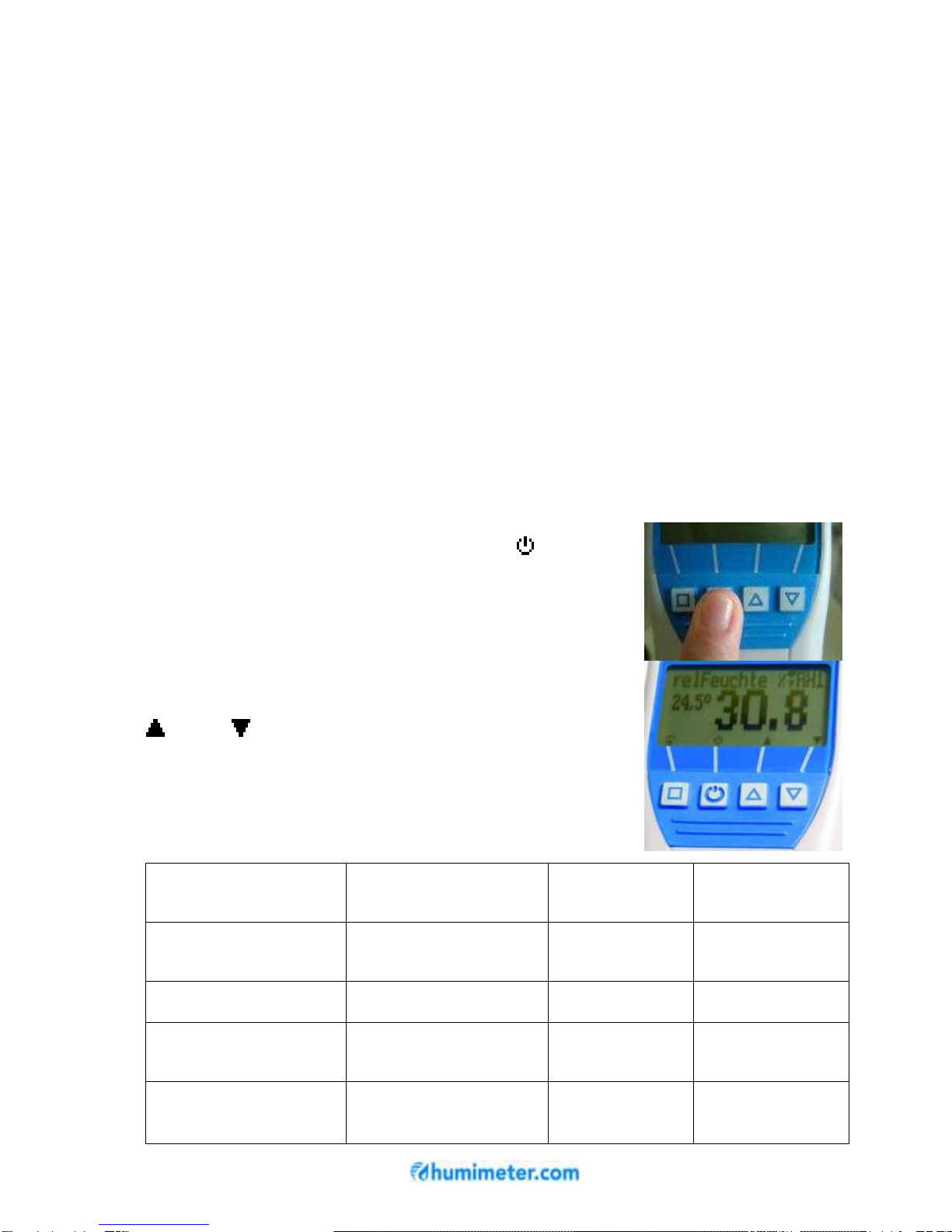

Switching on: Press for 3 seconds.

Changing the calibration curve: or .

Setting the time: Press three times - Options – Date / Time

Here you can set the date and time, according to the format indicated

(JJ.MM.TT), by pressing the button . When you have finished the input of

the year, press the button to adjust the month and then again the button

to adjust the day. For jumping from date to time also press the button .

When you have finished, press for saving date and time.

Datalog: Select your desired interval on the menu level Options – Log Time

using the arrow keys, and confirm by pressing OK. Now in the measuring

window appears in the store menu the symbol . By pressing this

symbol you can activate the AutoLog.

Info! For conserving battery power the device switches off

automatically when selecting a log interval of or longer than 1 minute,

and activates again for saving the logs!

For completing the AutoLog, switch on the device (if necessary) and press

the button. If you want to add supplier´s data please press the

button. You can also work on the supplier´s data subsequently.

Switching on the display lighting: Press the key briefly; the display

lighting switches off automatically after approx. 20 seconds. Pressing any

key activates the display lighting again, and the period for switching off again

is prolonged to 4 minutes (The display lighting time can be modified on menu

level Options – Light ON Time).

Switching off:

Press the

key for 5 seconds. The instrument switches off

when you stop pressing the key. The instrument switches off approx. 4

minutes after the last key has been pressed (The turn-off time can be

modified on menu level Options – Auto Off Time).

Other instrument functions – overview

Manual saving of single measuring values in a measurement series

Display of measuring series and measuring values directly on the

instrument

Printing the saved measuring series (only with PC interface and printer)

Transfer and saving of measuring series on a PC (only with PC

interface)

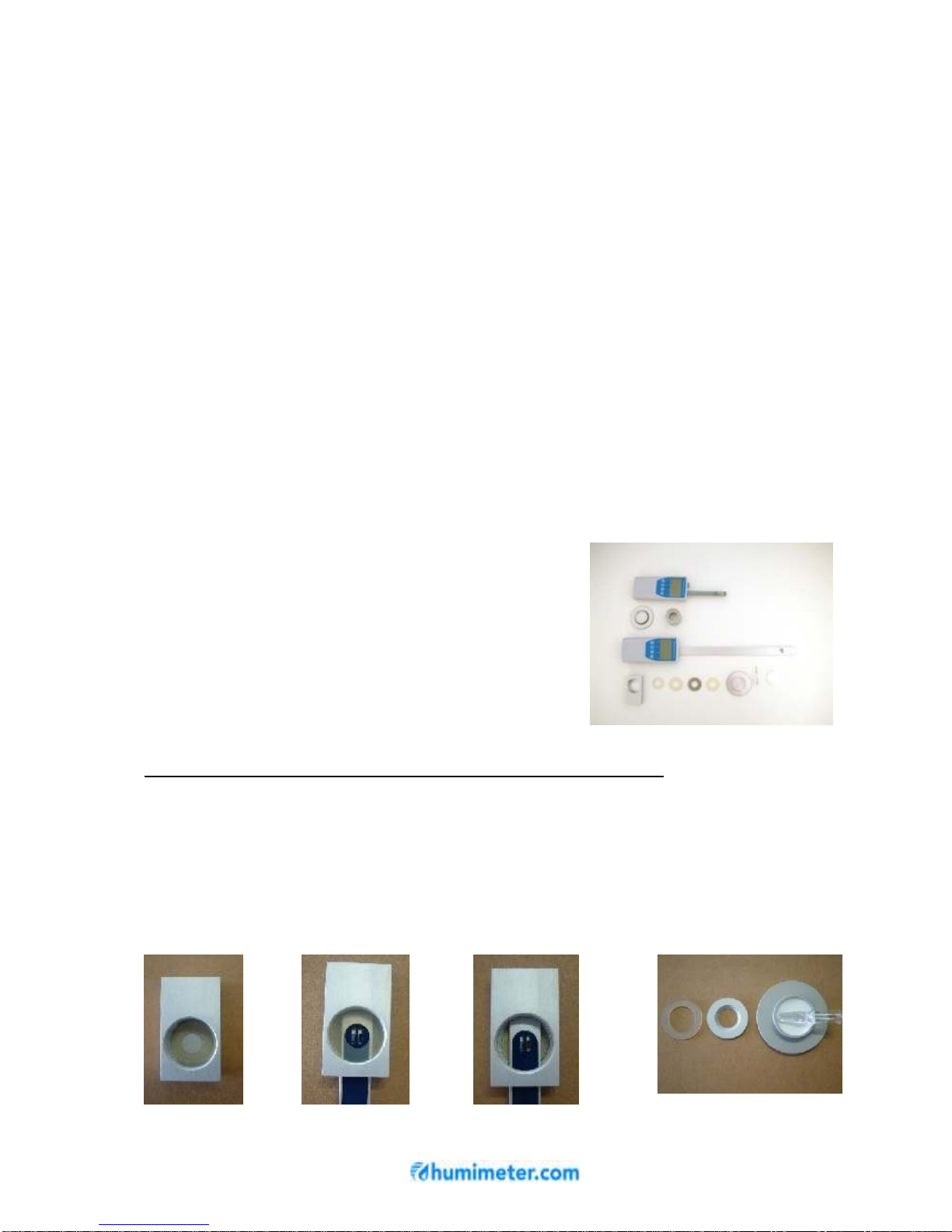

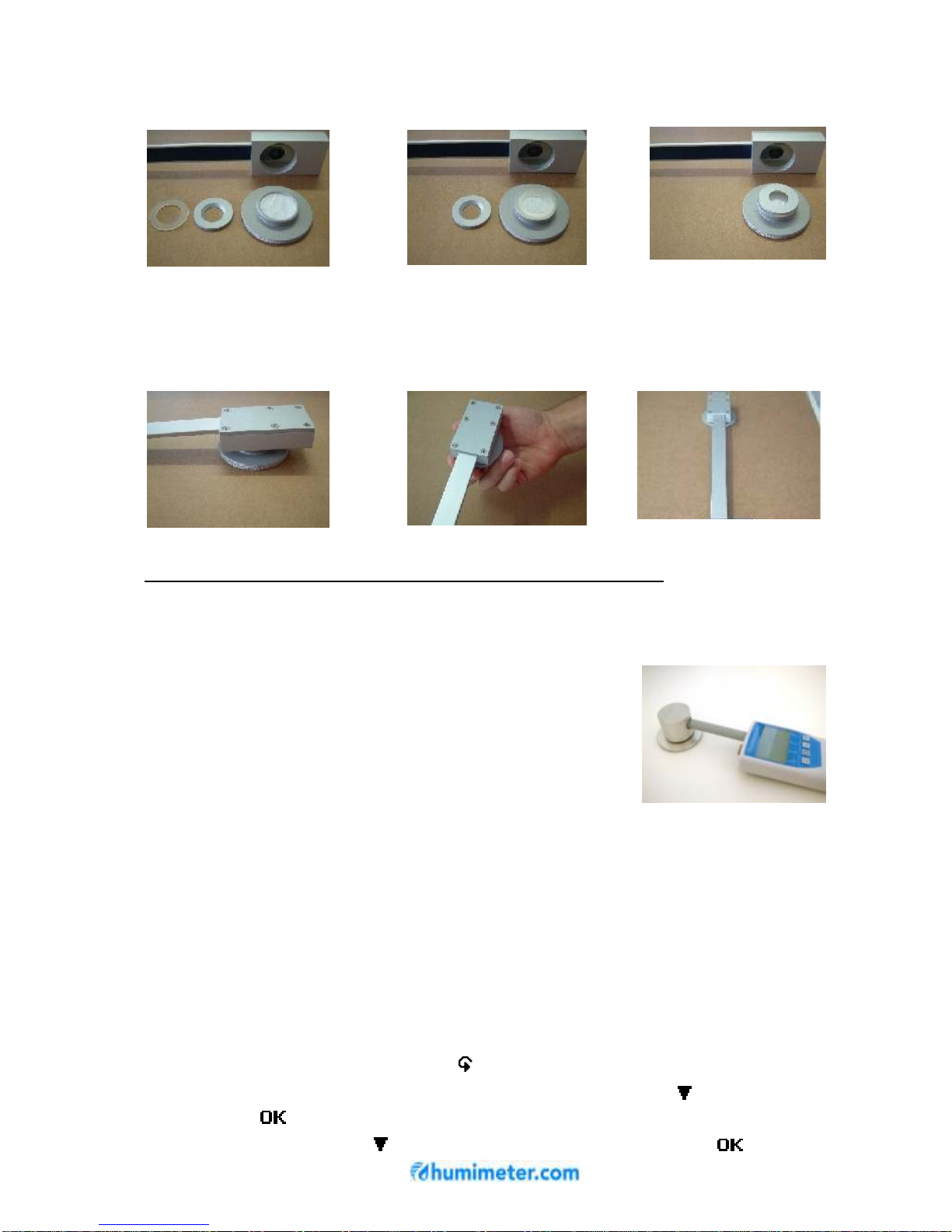

Automatic single-point adjustment at 50% humidity standard.

Display of the memory and battery status

Selection of the menu language (DE, EN, FR, IT, ES, RU)

Temperature can be shown in degrees Celsius or degrees Fahrenheit