3

Section 1: Safety

The HH500 is designed to produce an intense amount of torque.

PLEASE USE EXTREME CAUTION AT ALL TIMES.

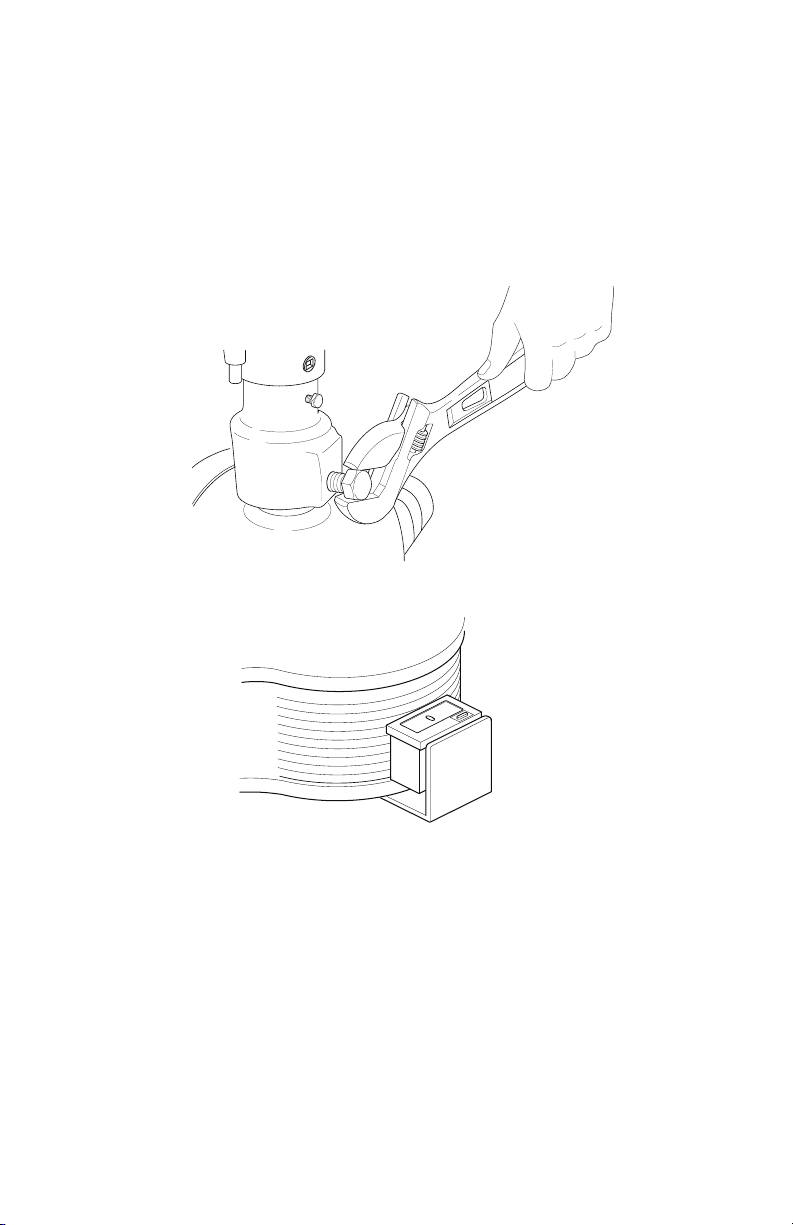

This tool has been designed to help operators open and close

valves. The tool can create in excess of 450 lb-ft of torque.

DANGER

The incorrect use of HH500 equipment may cause

serious injury. Read these instructions in their

entirety before using any HH500 products.

WARNING

Use caution when operating any power tool. Read

and follow the operating and safety instructions in

the product manual. Always wear safety goggles

and other appropriate safety items for protection.

CAUTION

Never apply manual torque to open or close a valve! ONLY

USE MOTOR POWER TO ACTUATE THE VALVE,

OTHERWISE, DAMAGE TO THE MOTOR MAY OCCUR.

WARNING

MAKE SURE THE REACTION HANDLE IS PULLING

AWAY FROM THE OPERATOR DURING USE. Misuse

could lead to loss of operator balance and potential fall

injury.