PG680/820 Frequency Inverter Programming

The PG680 & PG820 both come equipped with frequency inverters. The

functions of these frequency inverters are as follows:

•Maximise performance of the drive motors.

•Enable Forward/Reverse control of drive motors.

•Enable speed control of drive motors.

•Regulatory / Protective functions.

•Diagnostic & Servicing functions.

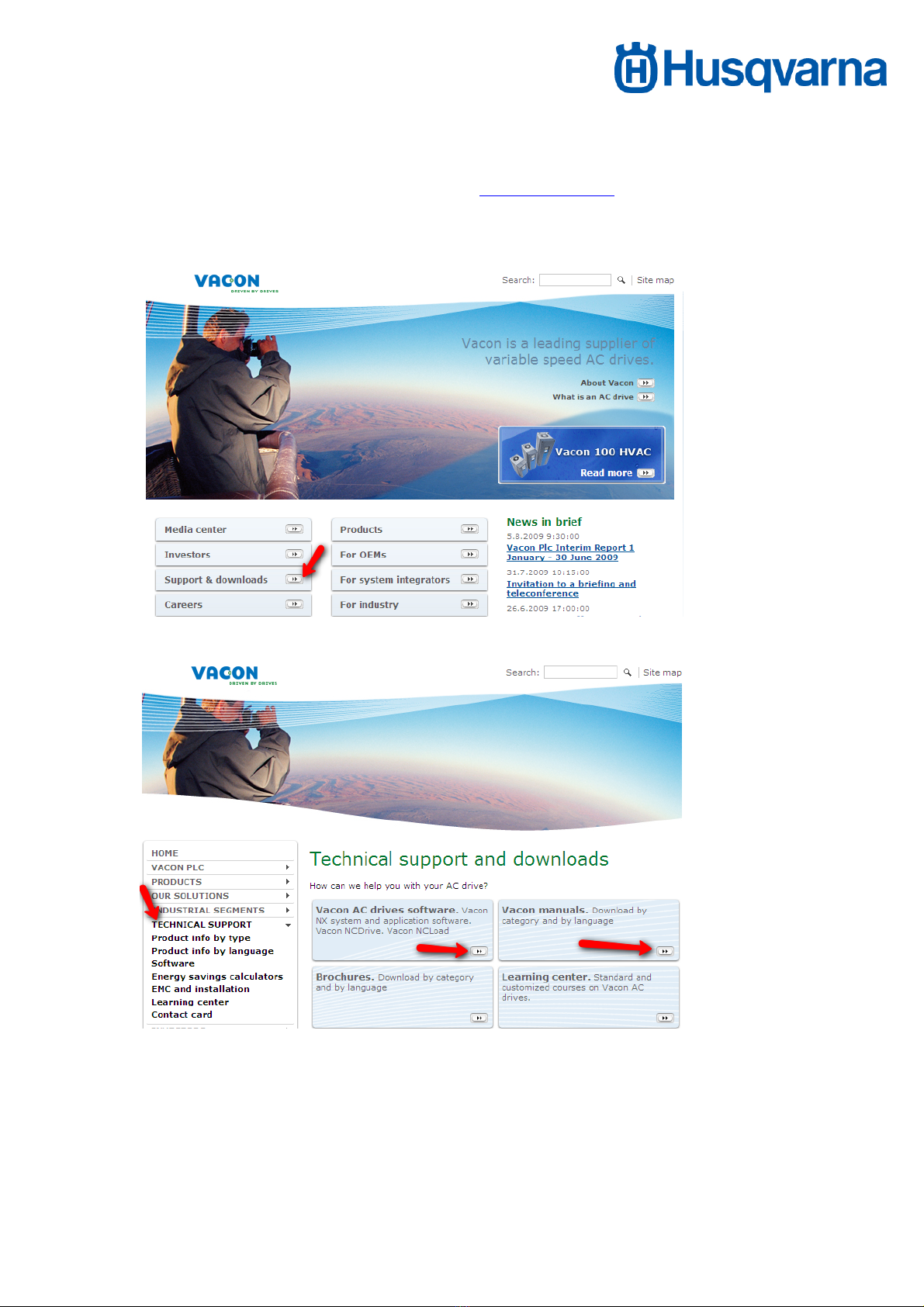

From time to time, updates will be made available to help further enhance the

above features. These updates can be uploaded into the frequency converters

using a personal computer / laptop device.

Two different software packages are required for such updates:

•NCLoad – installs operating system into frequency converter.

•NCDrive – installs settings / parameters specific for our application into

the frequency inverters.

The following manual covers:

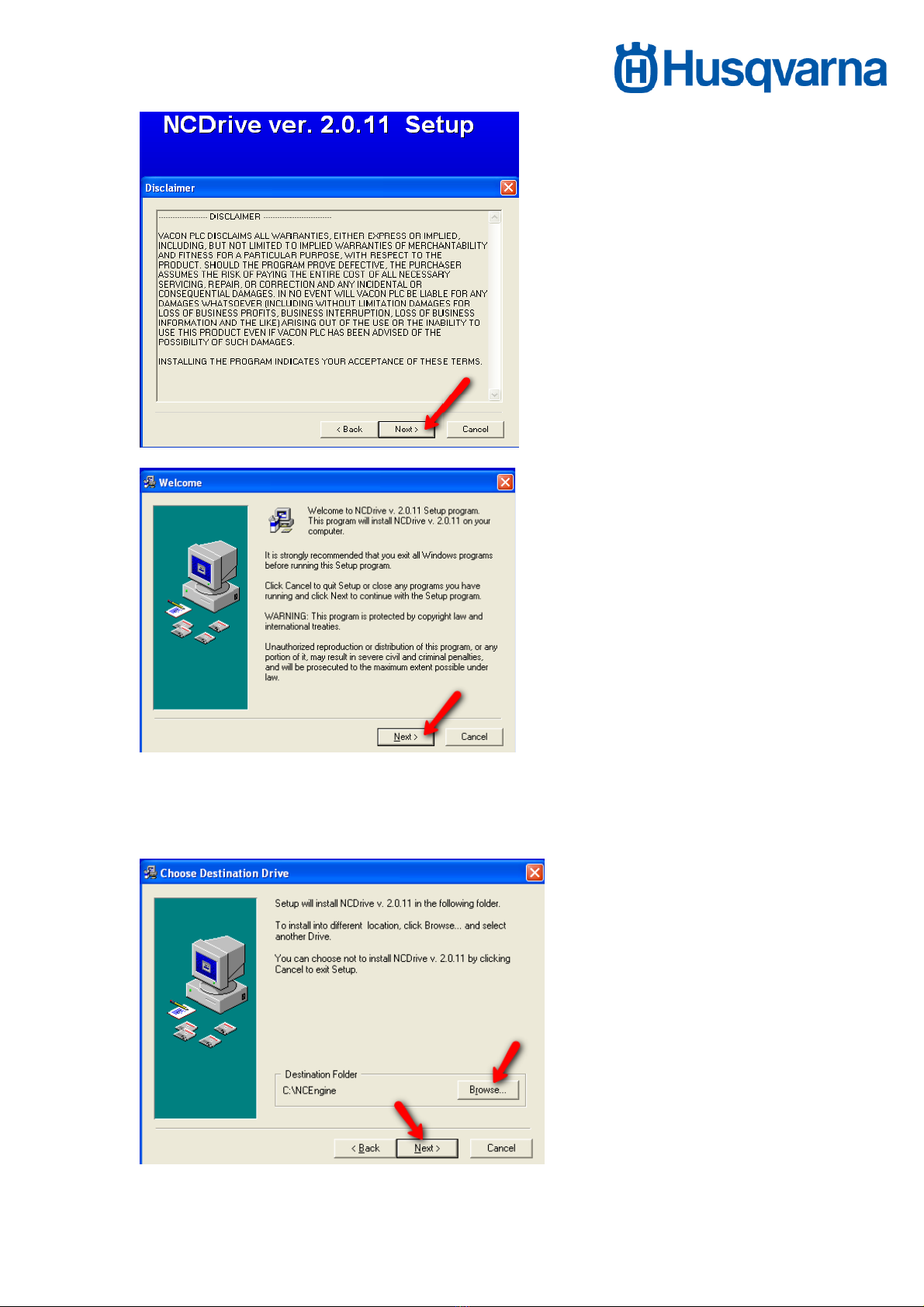

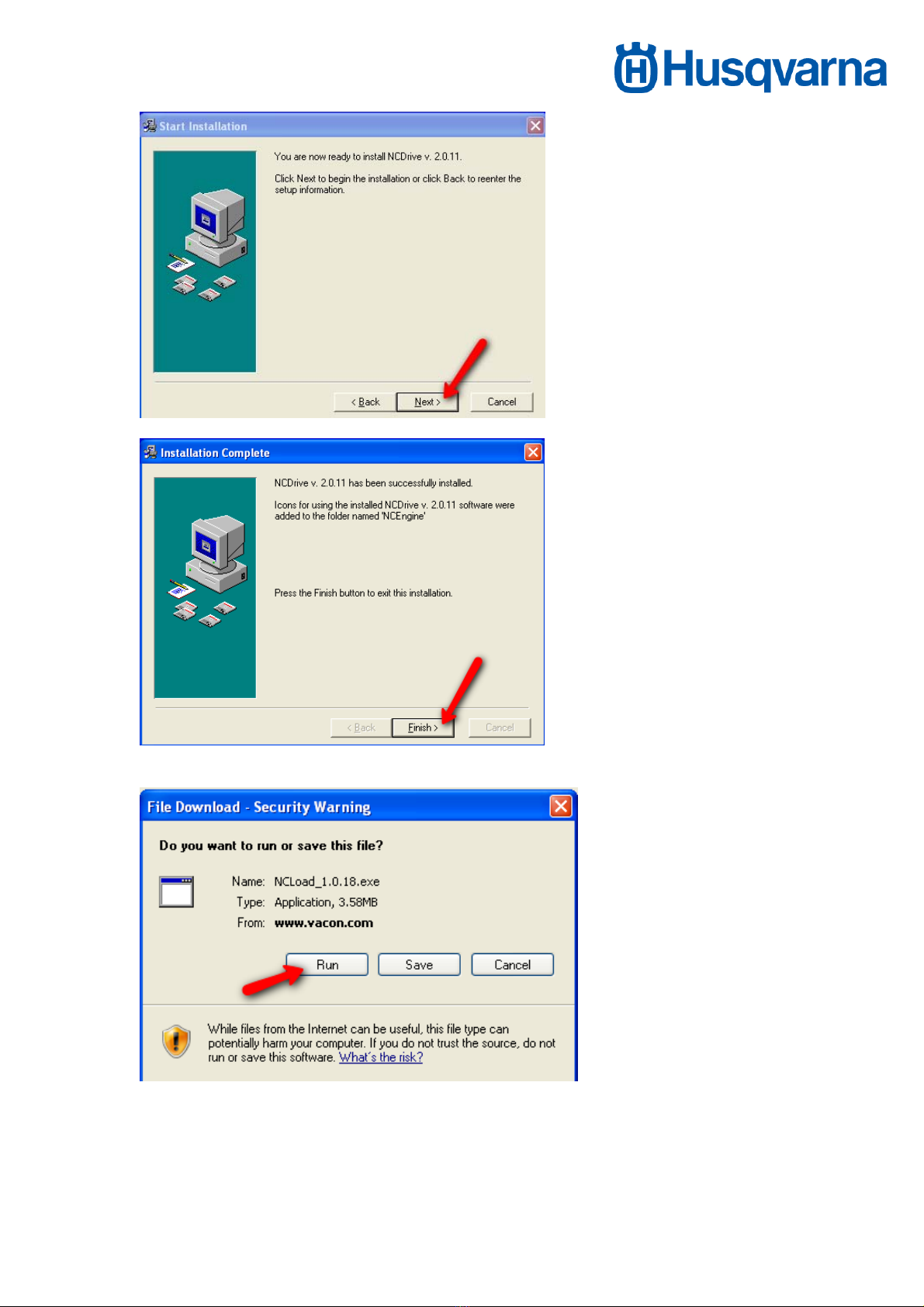

1. How to set-up the personal computer / laptop device which will be used

to install the updates to the frequency inverters.

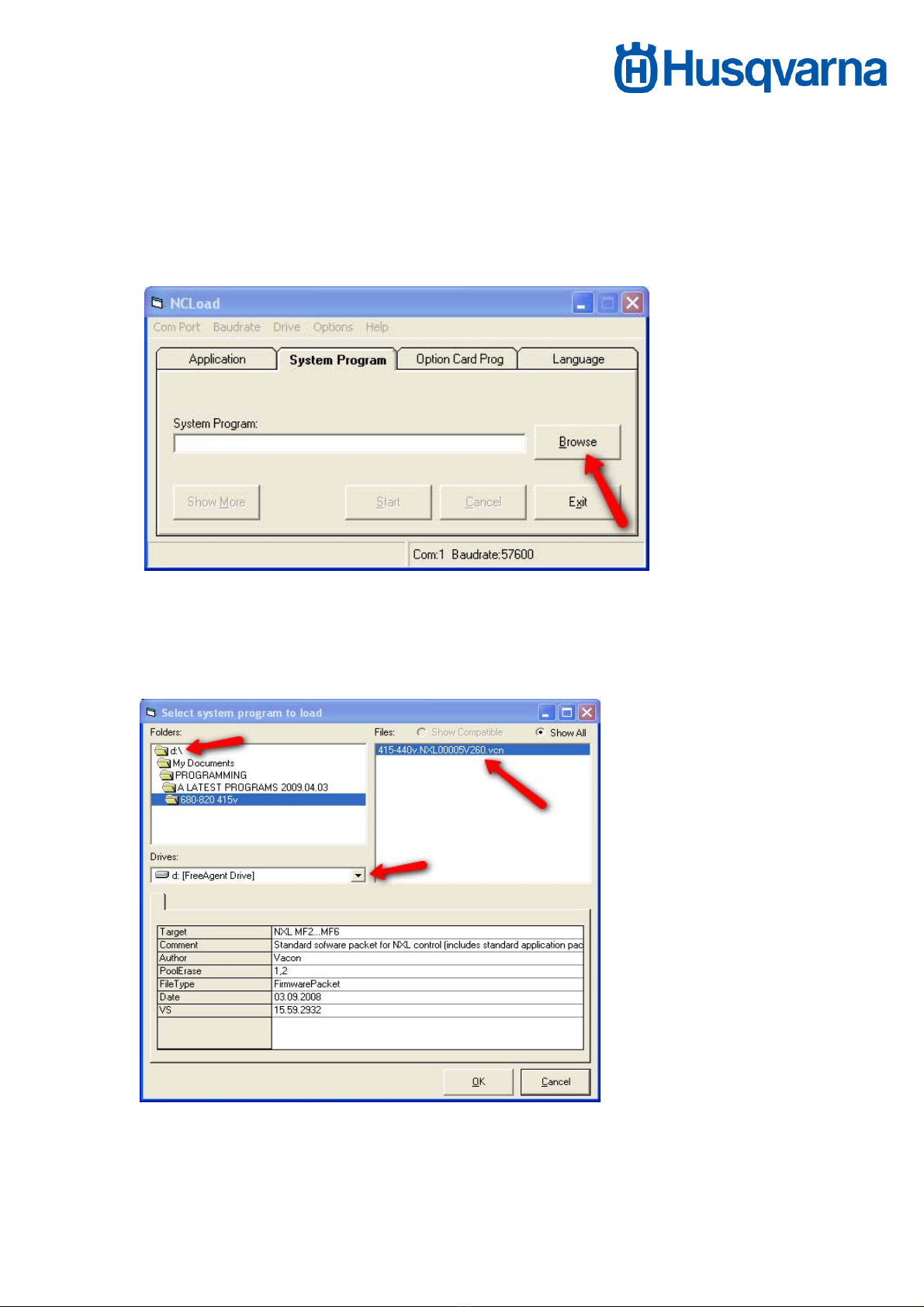

2. How to install the updates into the frequency converters.