OPTIONAL

KITS:

HEAVY-DUTY

LOWER

MAST

SUPPORT

KIT

(51467-10)

(Optional)

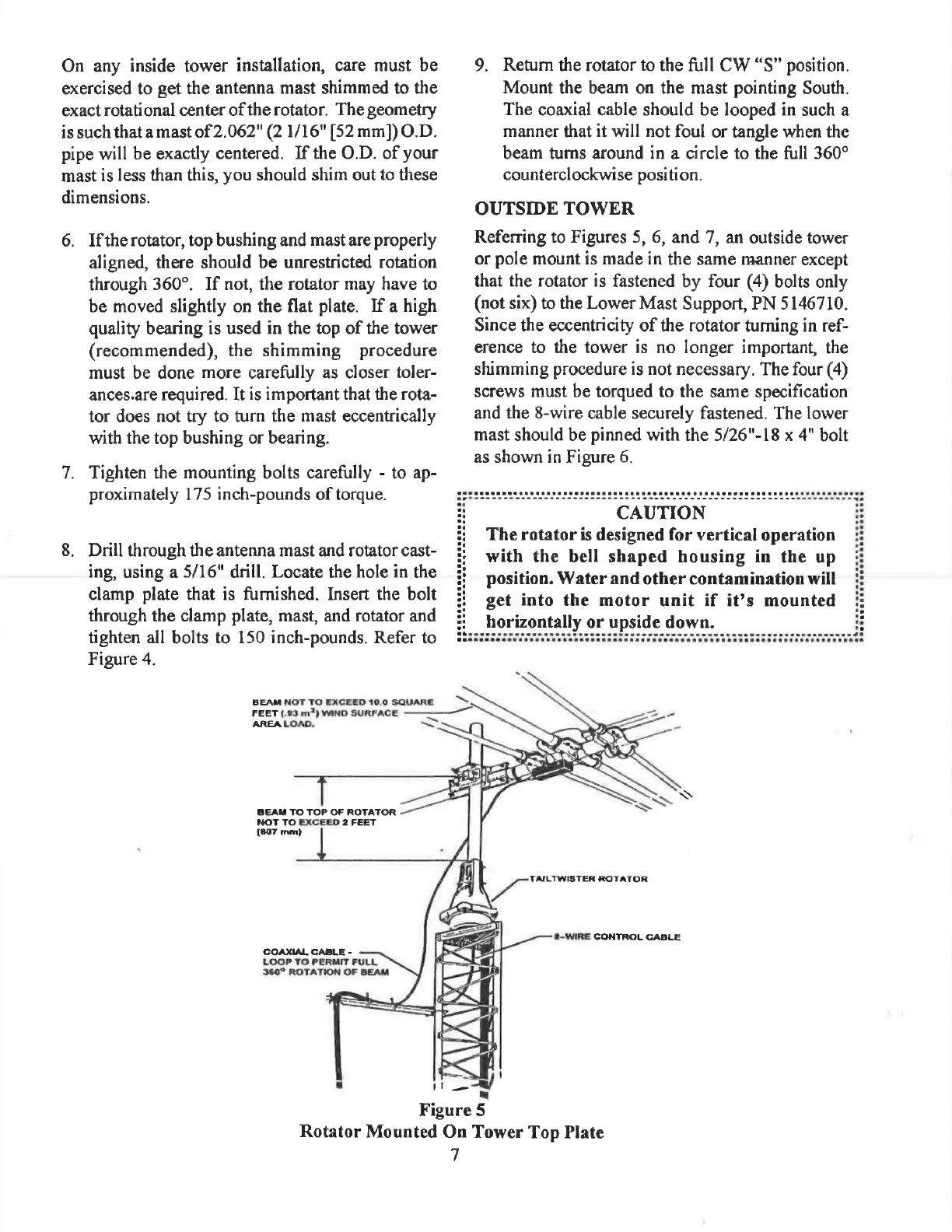

The

stock

Tailtwister

T2X

is

intended

to

mount

on

the

base

plate

inside

of

the

tower.

However,

in

some

instances,

outside

tower

or

mast

mounting

is

desired

as

per

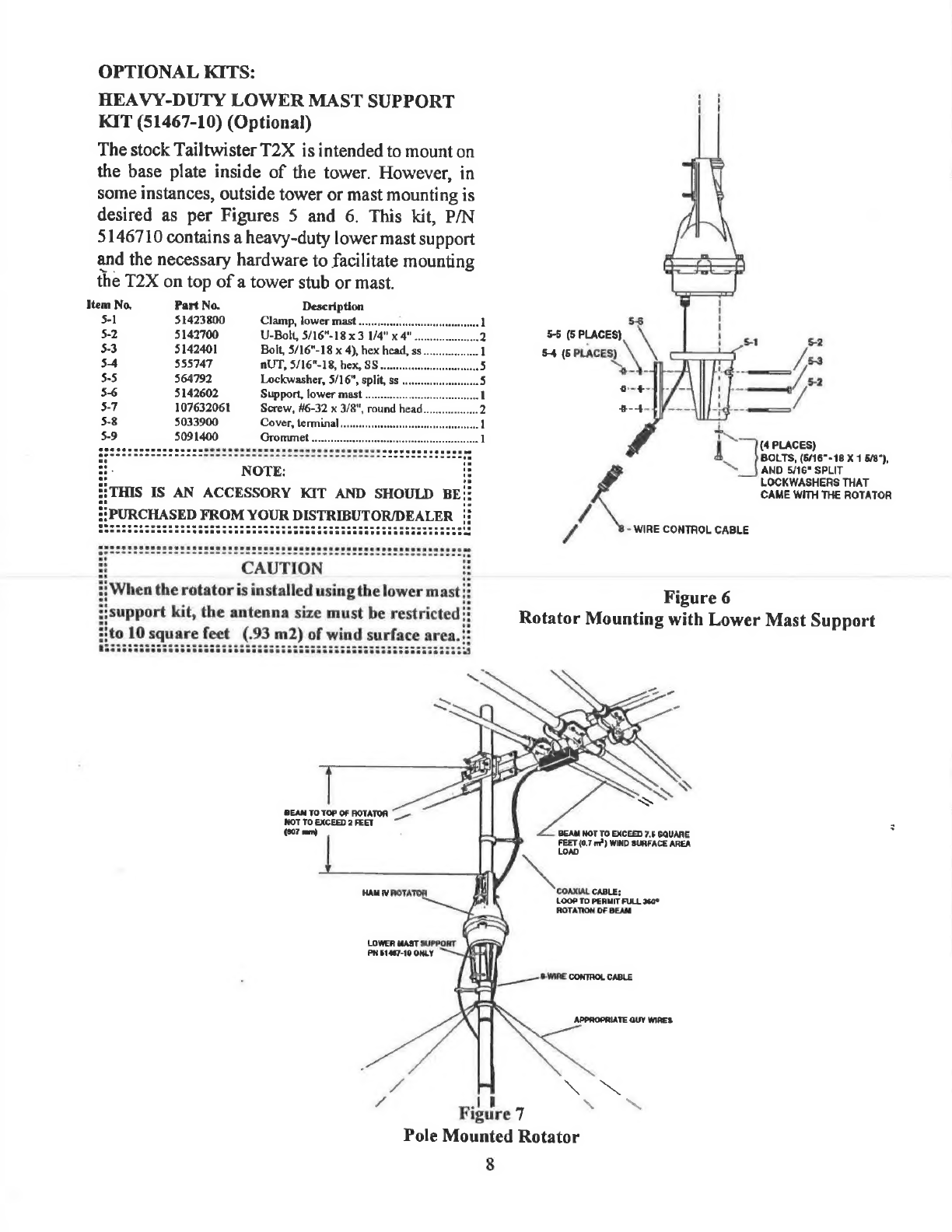

Figures

5

and

6.

This

kit,

P/N

5146710

contains

a

heavy-duty

lower

mast

support

and

the

necessary

hardware

to

facilitate

mounting

the

T2X

on

top

of

a

tower

stub

or

mast.

Item

No,

Part

No.

Description

5-1

51423800

Clamp,

lower

mast

...,..,..00

peteatts

ie

ies

ds

1

56

5-2

5142700

U-Bolt,

5/16"-18

x3

1/4"

x4"...

a2

5-5

(5

PLACES)

5-2

5-3

5142401

Bolt,

5/16"-18

x

4),

hex

head,

ss.

wl

54

(5

PLACES)

/

53

5-4

555747

AUT,

5/16"-18,

hex,

SS

oo.

L5

yh.

=

$-5

564792

Lockwasher,

5/16",

split,

ss

...

iS

beans

BS

5-2

5-6

5142602

Support,

lower

MaSt

.cccseeecec--

wl

aie

.

ae

5-7

107632061

Screw,

46-32

x

3/8",

round

head.

3

$-4-

5-8

5033900

Cover,

terminal...

wal

$-9

5091400

Grommet

.........

oe

|

(4

PLACES)

Go

cces

ssc

ca

eee

nan

CeB

Eee

Ree

ee

Ree

eee

eee

ec

eee

esesesacsass

BOLTs,

es

-18X

1

6/8°),

ee

AND

5/16"

SPLIT

2

NOTE

LOCKWASHERS

THAT

i

THIS

IS

AN

ACCESSORY

KIT

AND

SHOULD

BE!

CAME

WITH

THE

ROTATOR

PURCHASED

FROM

YOUR

DISTRIBUTOR/DEALER

|:

wf

-

WIRE

CONTAOL

CABLE

i

CAUTION

i

?}

When

the

rotator

is

installed

using

the

lower

mast}:

i

Figure

6

i

support

kit,

the

antenna

size

must

be

restricted?

Rotator

Mounting

with

Lower

Mast

Support

Hto

10

square

feet

(.93

m2)

of

wind

surface

area.:

ee

OSSBSSsSSsssessssscssssscccecsnssassescsesseseeeeeeceeeeeeeleaed

7

"

Sis

&

ae

ne

by

SSi

gi

|

a

oe

sai)

a

»

in

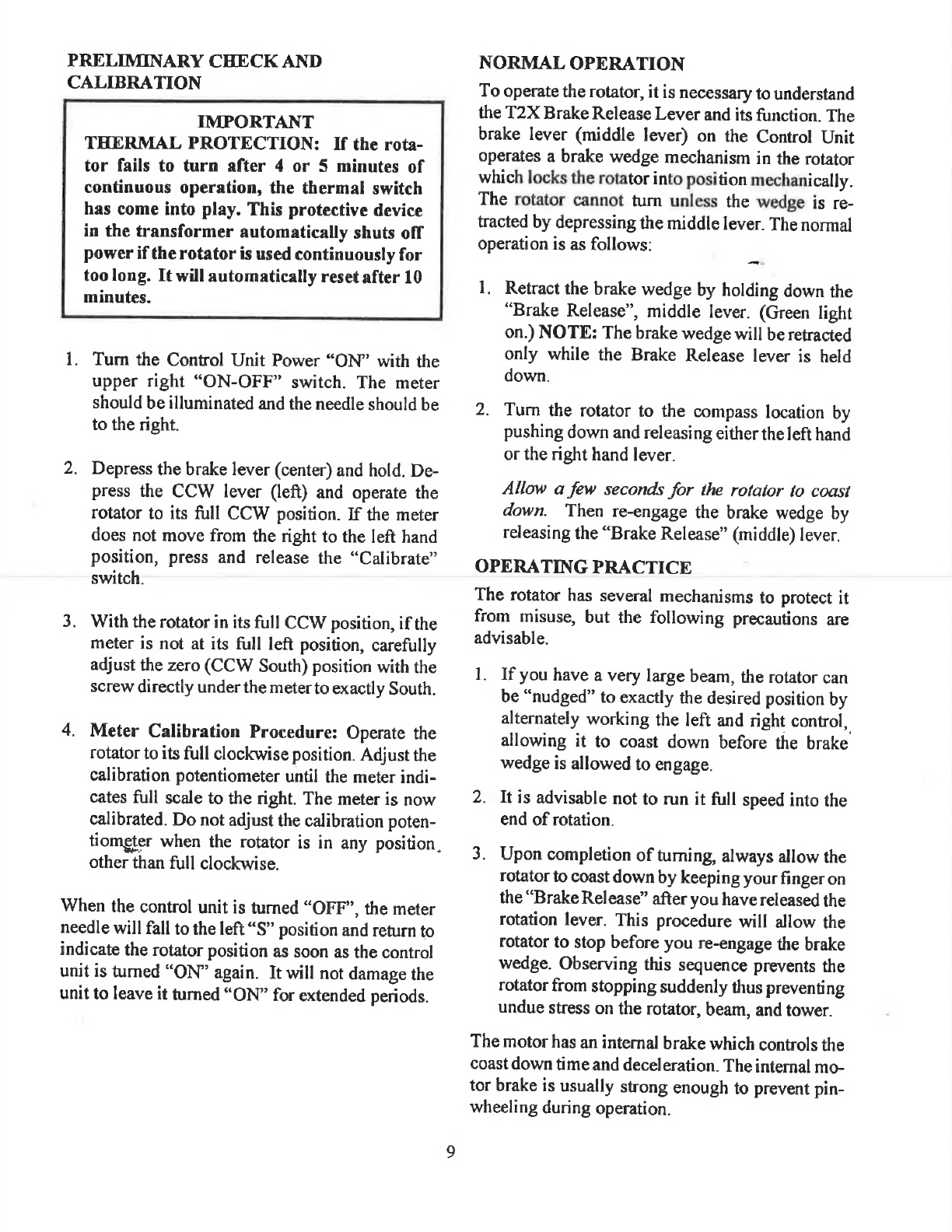

BEAN

TO

TOP

OF

ROTATOR

~

NOT

TO

EXCEED

2

FEET

(007

mm)

=

BEAM

NOT

TO

EXCEED

7.6

GQUARE

—>

FEET

(0.7

mo?)

WIND

SURFACE

AREA

|

ae

LOAD

HAM

WEARER

Va

i

toon

to

penne

FULL

36a°

ROTATION

OF

BEAM

-y

LOWER

MAST

SUPPORT

\aerp

PN

61467-10

ONLY

i

/\L

G-WIRE

CONTROL

CABLE

J—3—|}

Co

KF

APPROPRIATE

QUY

WIRES:

we

a.

SS

4

J

\

SS

Figure

7

Pole

Mounted

Rotator

8