Date Printed: 07/11/2011 “Commercial-in-Confidence” Page Number: 8

Hyden Engineering

1.3 Foam system

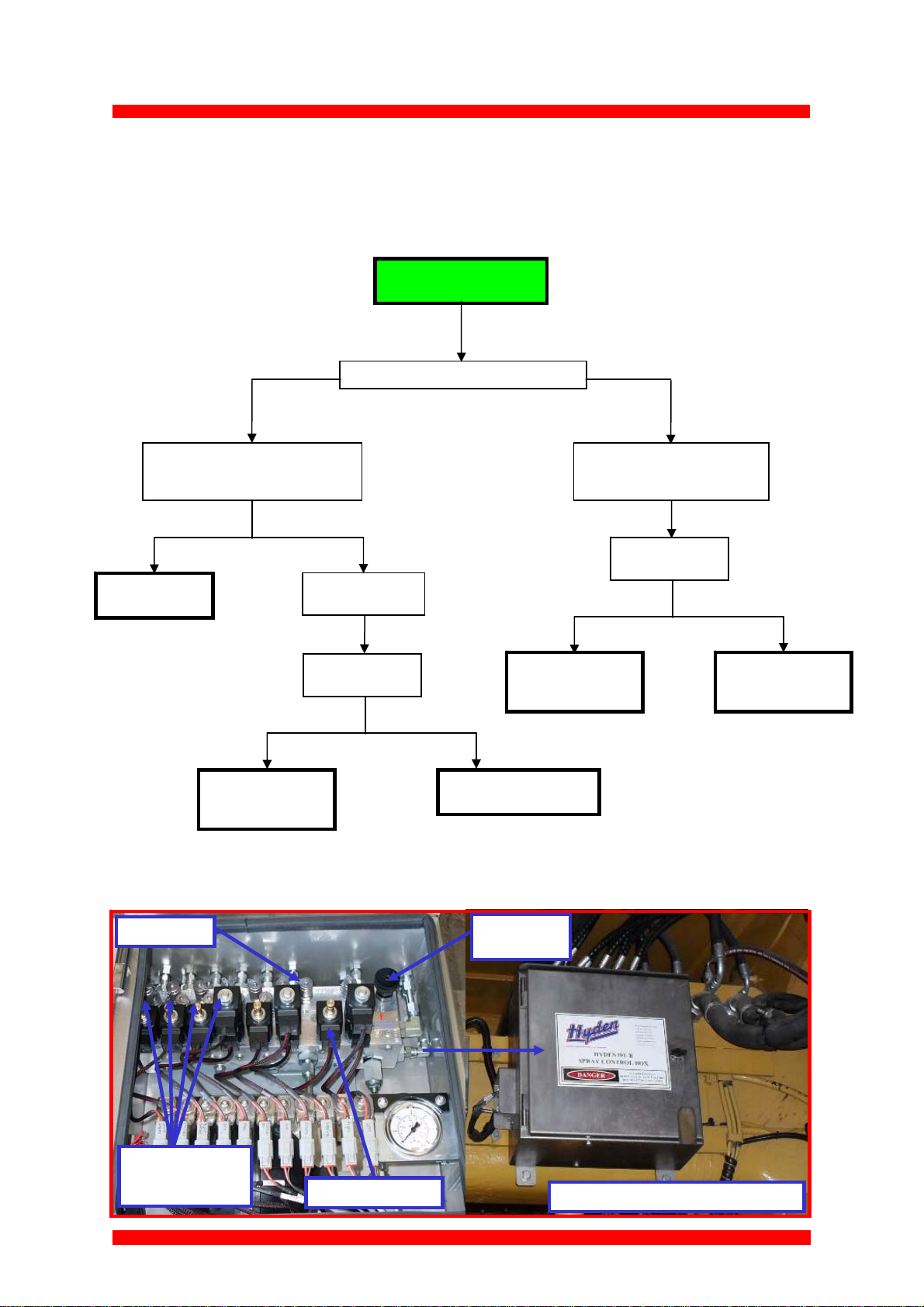

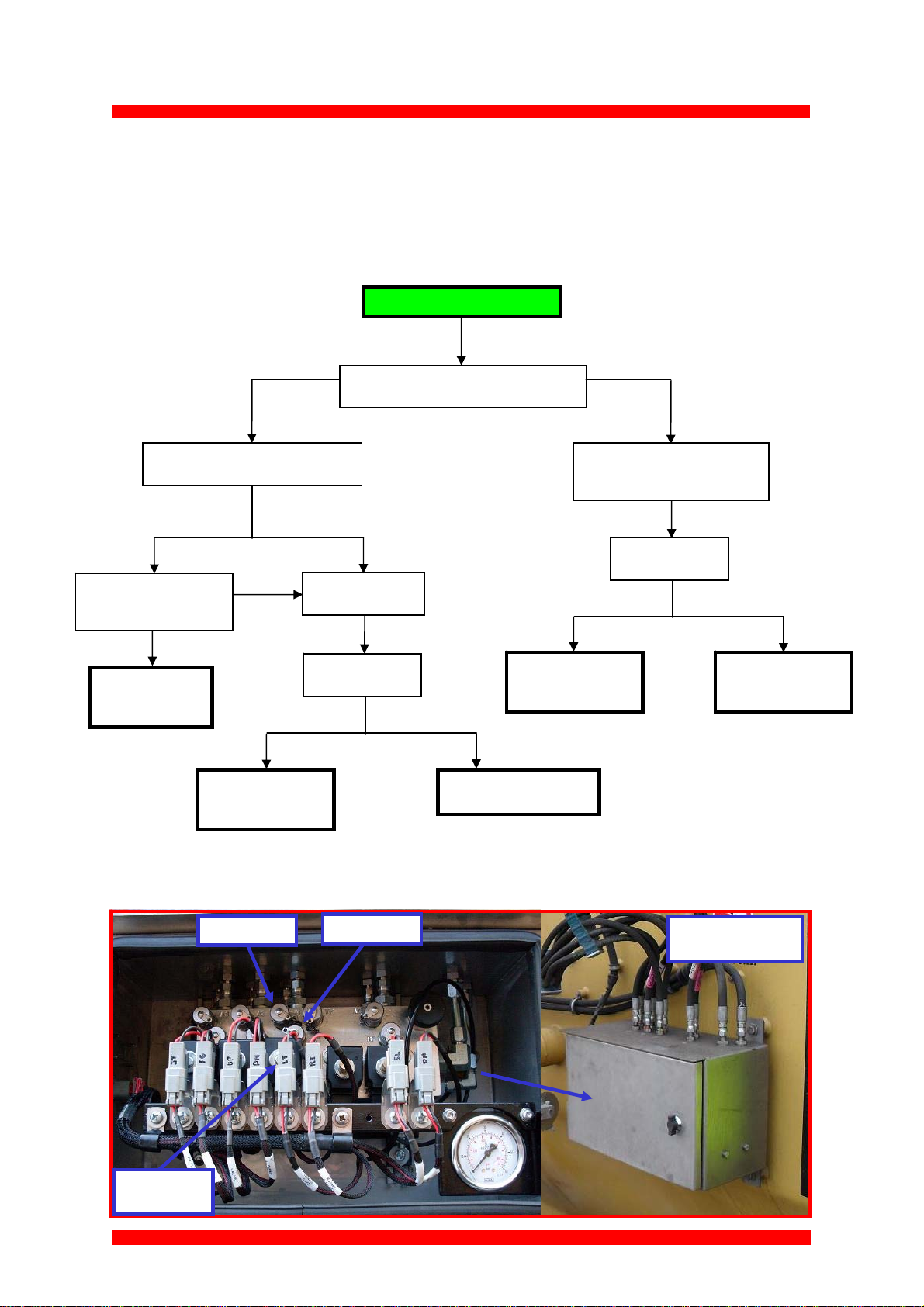

1.3.1 System Diagnostics

Foam system not working

Yes No

Yes No

There is a fault with the

foam pump module.

Did this fix the

problem?

Yes No

Congratulations you

have fixed the

problem.

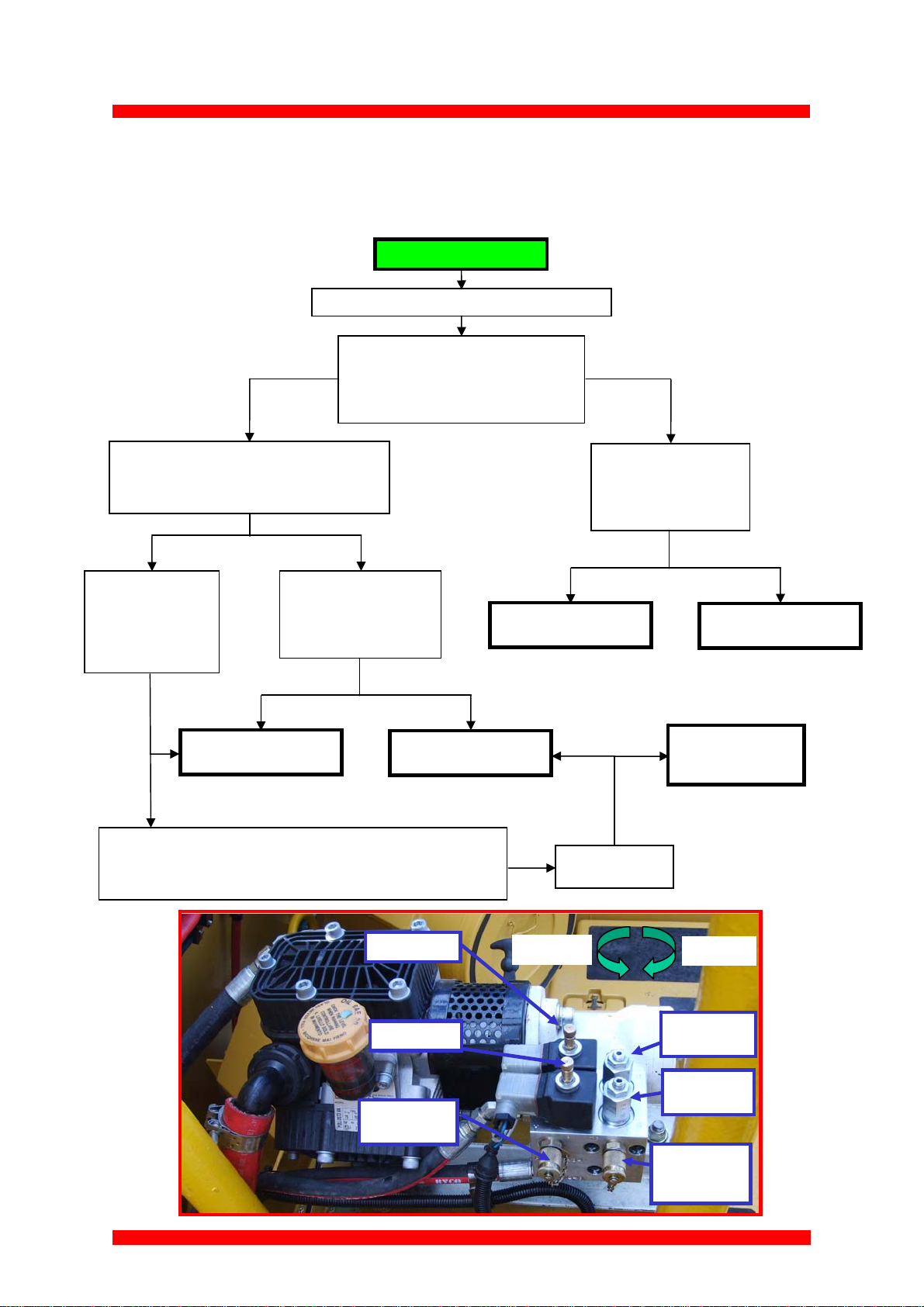

Ensure the foam inlet ball valve is completely open.

Increase the Vari-rate to 40%.

Does the MID foam LED illuminate and the drive

shaft continue to rotate?

Engage the LOW foam

manual override.

Does the foam system start

to work?

While using the remote cannon set the Vari-

rate to low and start the foam system.

Does the Low foam LED illuminate and the

drive shaft start to rotate?

Increase the Vari-rate

further to 80%.

Do both the Low and

Mid LED plug

illuminate ?

There is an electrical fault.

See electrical diagnostics

Engage the MID foam

manual override.

Does the foam system start

to work ?

There is a fault with the

foam pump module.

Yes No

There is an electrical fault.

See electrical diagnostics

No

Setup a REV counter on the drive shaft.

Vari-rate @ low = 160-rpm Adjust Low flow control as required

Vari-rate @ 40% = 340-rpm Adjust Mid flow control as required

No Yes

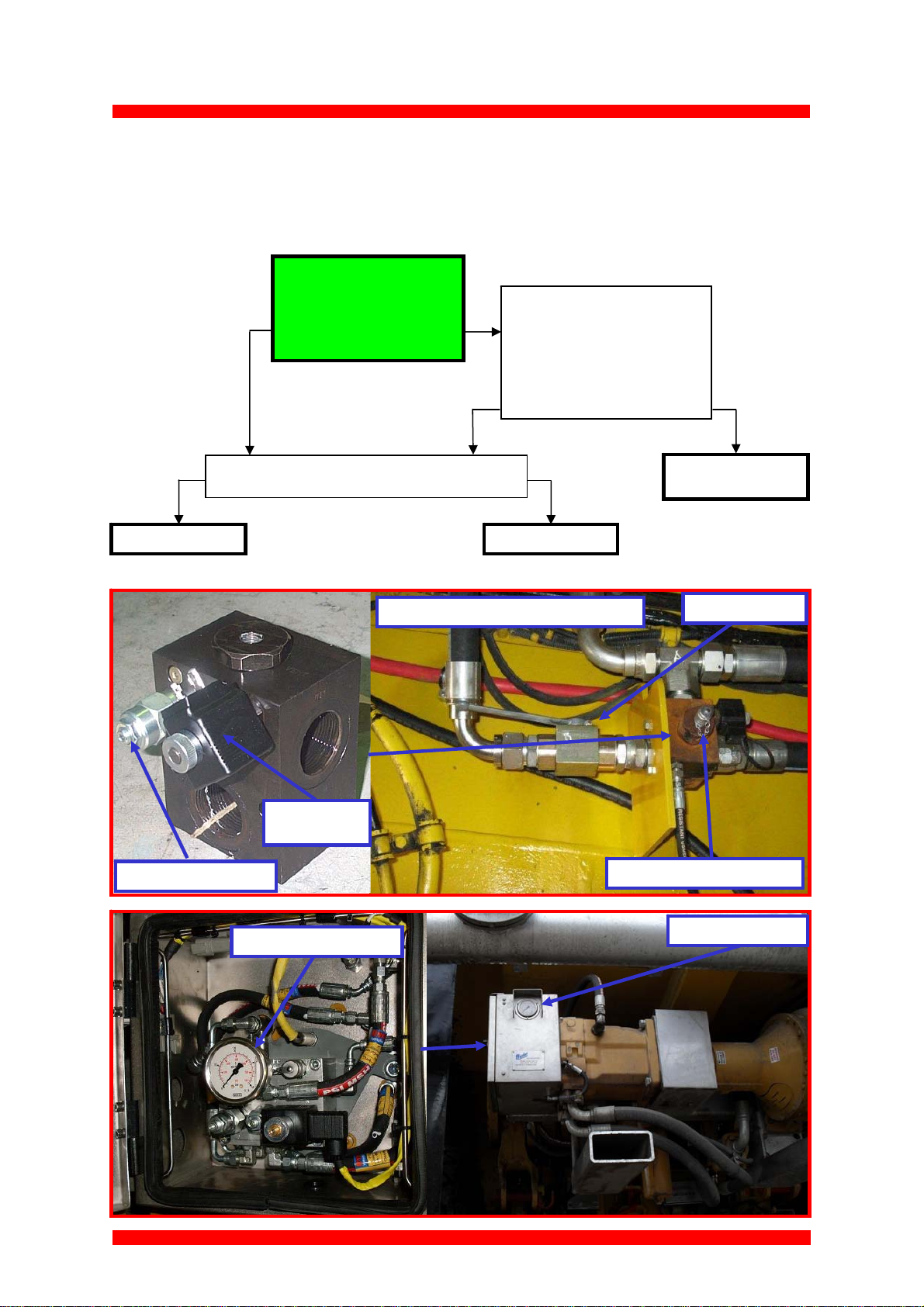

Inlet pressure

test point

LOW foam

MID foam

MID foam

flow control

LOW foam

flow control

Increase

Decrease

Motor drive

pressure test

point