Page 6 RX-20/CMX-20

HydraMaster Corporation

Cleaning Information

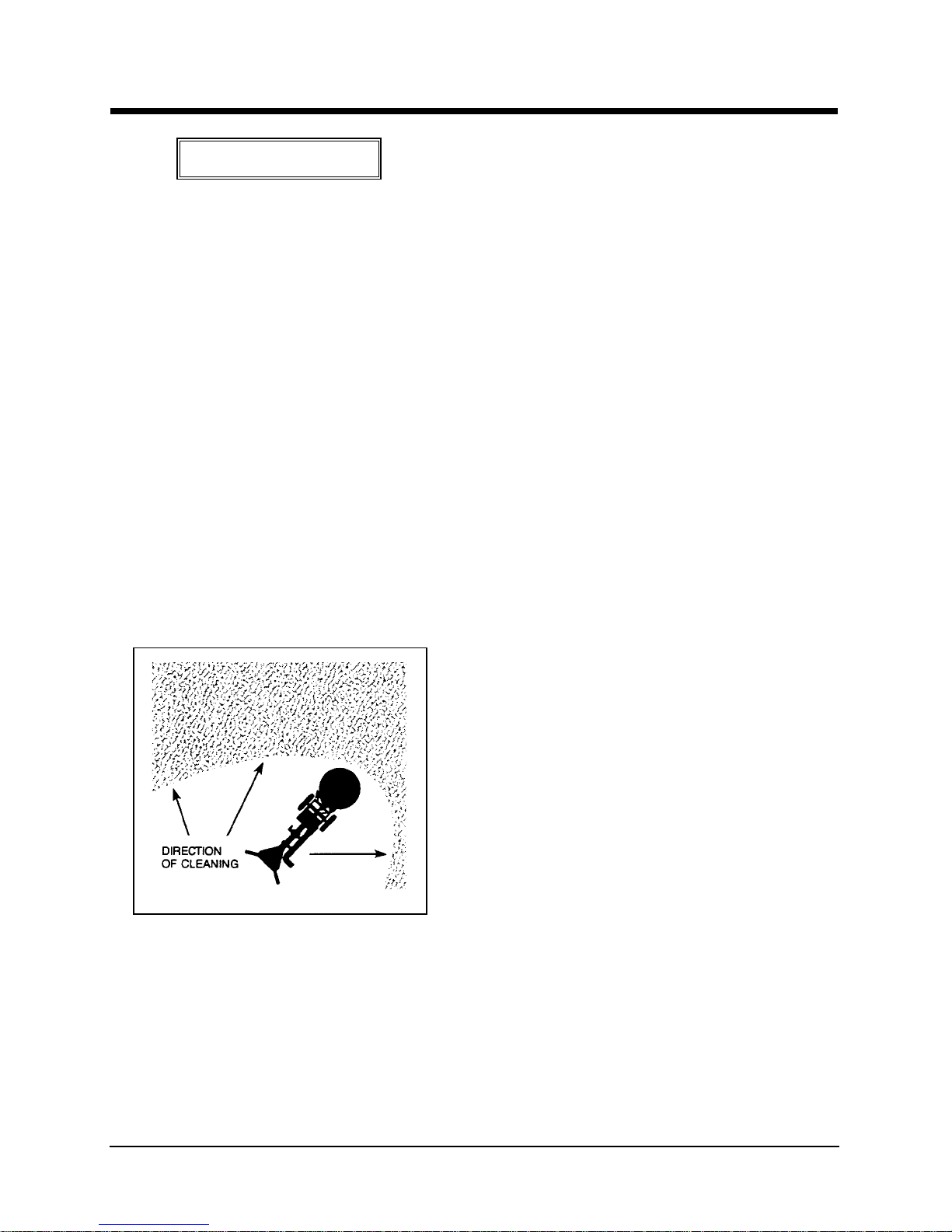

Cleaning Patterns

For regular carpet cleaning use an over-

lapping arc pattern three times over the

same area (two passes with solution and

one pass for drying). When cleaning

carpers, first clean in circular pattern,

then use the overlapping arc pattern to

dry the area.

Note: Dirtiest areas may require two

or more cleaning passes. Using either

pattern, you should develop a comfort-

able rhythm. To obtain maximum per-

formance from your RX-20, move it

slowly and deliberately with a 50% over-

lap, giving it time to clean and extract.

(Unlike a manual wand, the RX-20 is

doing the work you had to do in the

past) A steady pace rather than a fren-

zied one will increase efficiency and

production and decrease fatigue.

The Following Cautions Should

Be Observed While Cleaning:

1. DO NOT operate your RX-20 over

metal floor moldings. Damage to both

the molding and the cleaning head will

result.

2. DO NOT operate your RX-20 on

hardwood floors.

3. DO NOT operate your RX-20 over

loose or unraveled carpet seams.

The cleaning head may catch and

cause further damage.

4. DO NOT operate your RX-20 on

concrete floors. It will develop sharp

edges on the extraction heads that

will damage carpet fibers.

5. DO NOT clean over the edge of a

loose carpet. Instead, clean only up

to the edge. Damage may occur

should the extraction heads catch

the loose carpet.

Special Information

During the cleaning of some plush car-

pets you may notice a “pilling” effect.

With an RX-20, loose yarns form balls

and are kicked aside as the cleaning

heads revolve. This is normal when ag-

gressive cleaning or even normal vacu-

uming takes place, as evidenced by a

number of dead, loose yarns in the

vacuum cleaner bag. These loose yarns,

in most cases, are short staple yarns or

filler yarns used to give the carpet a

denser appearance. Because your RX-

20 weighs approximately 90 pounds and

rests on five four-inch cleaning heads,

the yarns are not sucked up into the

vacuum heads as they are with a

vacuum cleaner or old-style cleaning

wand.

8/4/99