TABLE OF CONTENTS

Section Page

Foreword .............................................................................................................................. 1

Description and Operation ................................................................................................. 2

Introduction.......................................................................................................................... 2

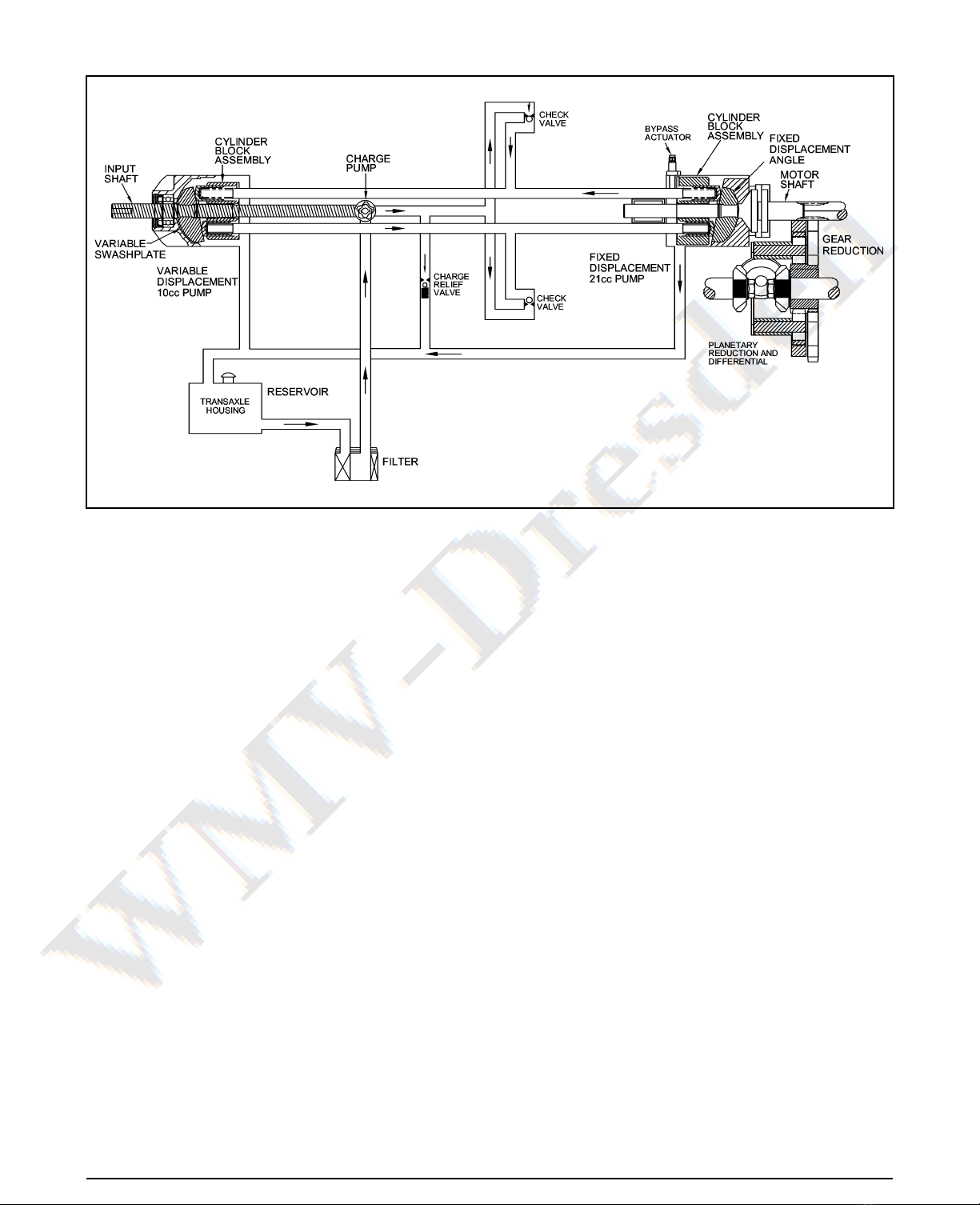

General Description ..................................................................................................................................... 2

Introduction .................................................................................................................................................. 2

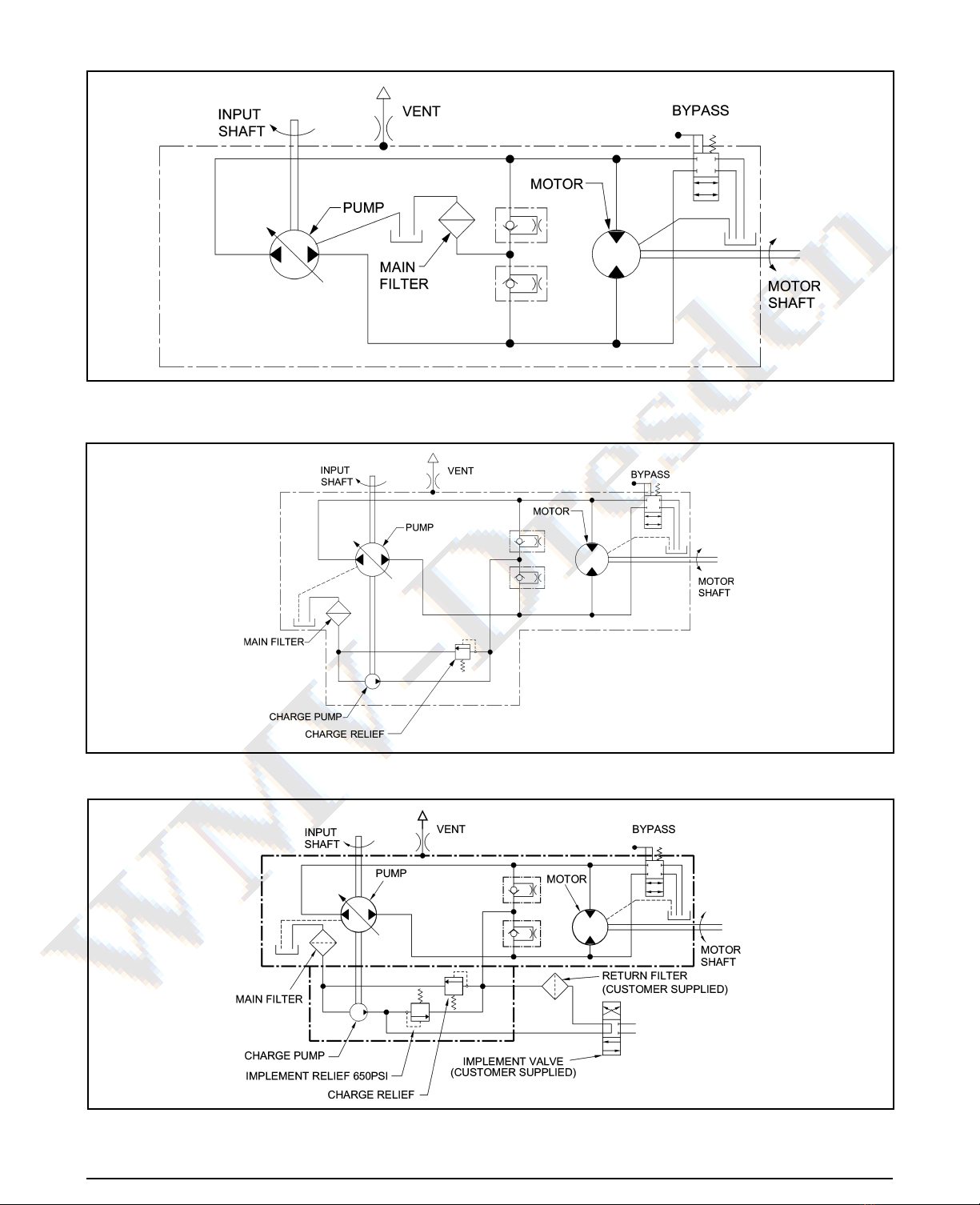

Hydraulic Schematic ................................................................................................................................. 3-5

Product Identification ................................................................................................................................... 6

Technical Specifications............................................................................................................................... 7

Safety.................................................................................................................................... 8

Personal Safety............................................................................................................................................ 8

Tool Safety ................................................................................................................................................... 8

Work Area Safety ......................................................................................................................................... 8

Servicing Safety ........................................................................................................................................... 8

Troubleshooting .................................................................................................................. 9

Service and Maintenance.................................................................................................. 10

External Maintenance ................................................................................................................................ 10

Service and Maintenance Procedures ....................................................................................................... 10

Fluids ..........................................................................................................................................................11

Brake Maintnenance .................................................................................................................................. 12

Return to Neutral Setting Foot Control....................................................................................................... 13

Purging Procedures ................................................................................................................................... 14

Repair ................................................................................................................................. 15

General Instructions................................................................................................................................... 15

Required Tools ........................................................................................................................................... 15

Torque Specifications................................................................................................................................. 15

Transaxle Removal .................................................................................................................................... 15

Limited Disassembly .................................................................................................................................. 15

How To Use This Manual ........................................................................................................................... 16

Brake Assembly .................................................................................................................................... 17,18

Bypass Assembly....................................................................................................................................... 19

Control Assembly .................................................................................................................................. 20,21

Seal Kit Replacement ................................................................................................................................ 22

Torque Bracket Assembly .......................................................................................................................... 23

Fan and Pulley Assembly........................................................................................................................... 24

Input Shaft Assembly ................................................................................................................................. 25

Auxiliary Pump ........................................................................................................................................... 26

Charge Pump Assembly ............................................................................................................................ 27

Lower Housing/FIlter/Manifold Assembly.............................................................................................. 27,29

Planetary Differential Assembly ............................................................................................................ 30-33

Motor/Center Section/Pump Assembly ................................................................................................. 34-36

Directional Control Assembly ..................................................................................................................... 37

Transaxle Installation ................................................................................................................................. 38

Assembly After a Complete Teardown ....................................................................................................... 38

Sealant Application .................................................................................................................................... 39

Parts List ....................................................................................................................... 40-43

Glossary of Terms ........................................................................................................ 44,45