5

TROUBLESHOOTING

Burner Will Not Fire See Flow Chart 1, page 6

Burner Will Not hut Down See Flow Chart 2, page 7

Temperature Display Exceeds

High Limit etting

Under normal operation, boiler temperature will continue to rise after the control shuts off

the burner. This condition, known as “thermal stacking”, results from hot boiler surfaces

continuing to release heat into the boiler water.

No or Insufficient

Domestic Hot Water

For boilers equipped with a tankless coil, make sure the low limit setting on the HydroStat

is set properly. NOTE: If the low limit setting is dialed fully counter clockwise, it will shut

off the low temperature maintenance feature and will function as a cold start control. If

installed with an indirect water heater, insure that the end switch in the relay box

controlling the indirect water heater is connected to the I1-I2 terminals. This will insure

that the domestic water calls are prioritized. (see “Heating-With Indirect Water Heater” on

page 3).

Boiler Will Not Maintain

Low Limit Temperature

Check for overlapping high temperature setting. If the high limit setting is set below the

low limit setting, the control will default to the high limit setting and the corresponding

high limit differential setting.

House Will Not Get

or tay Warm

1. Check for air-bound radiators. 2. Check thermostat settings including heat anticipator

settings (common on non-digital thermostats). 3. Check the Economy setting. The

Economy feature, much like outdoor reset controls, lowers average boiler temperature

and can slow or, in some cases, prevent the house from coming up to temperature.

Move to a lower setting (see “Setting the Economy Feature” on page 4).

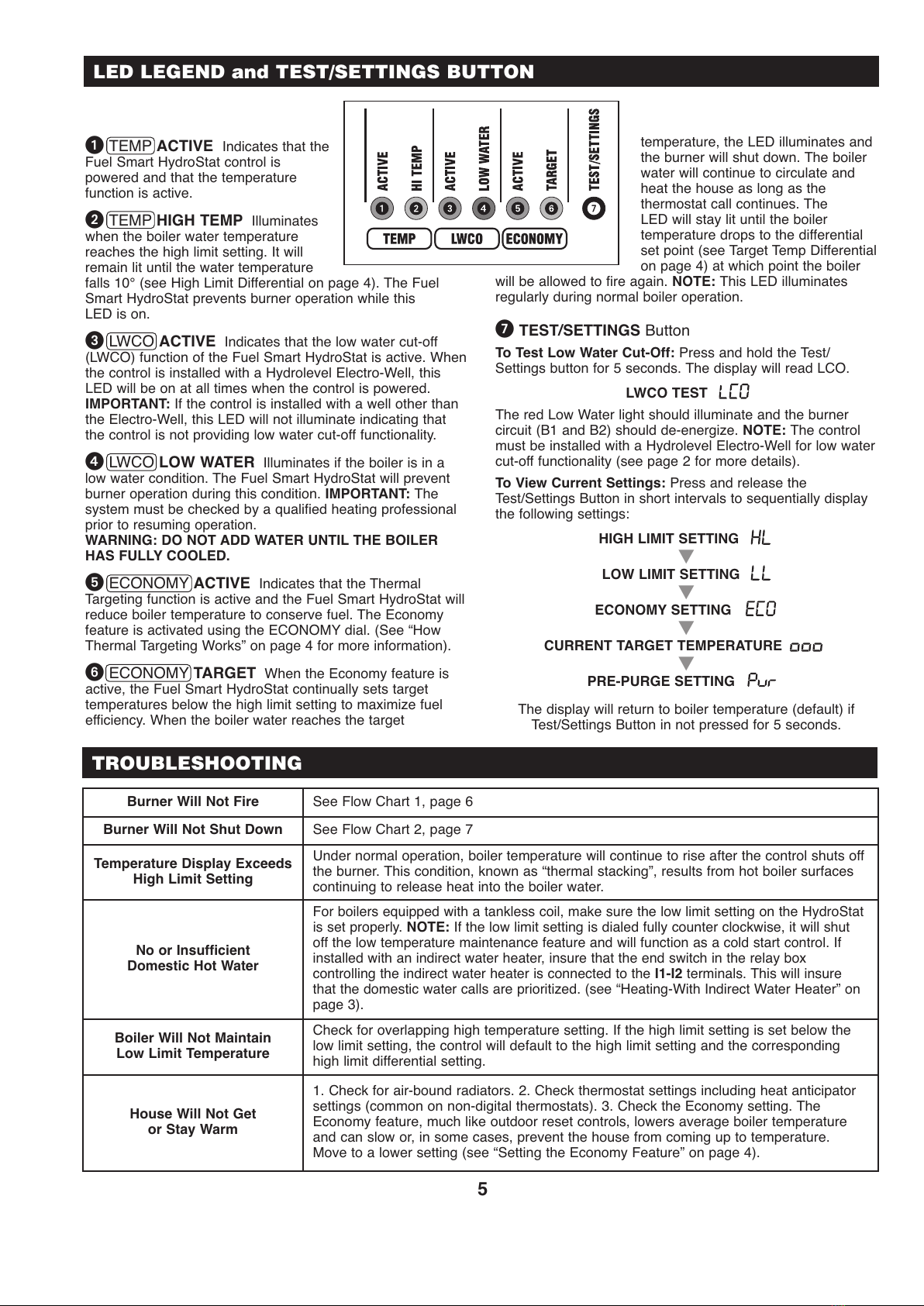

TEMP ACTIVE Indicates that the

Fuel Smart HydroStat control is

powered and that the temperature

function is active.

TEMP HIGH TEMP Illuminates

when the boiler water temperature

reaches the high limit setting. It will

remain lit until the water temperature

falls 10° (see High Limit Differential on page 4). The Fuel

Smart HydroStat prevents burner operation while this

LED is on.

LWCO ACTIVE Indicates that the low water cut-off

(LWCO) function of the Fuel Smart HydroStat is active. When

the control is installed with a Hydrolevel Electro-Well, this

LED will be on at all times when the control is powered.

IMPORTANT: If the control is installed with a well other than

the Electro-Well, this LED will not illuminate indicating that

the control is not providing low water cut-off functionality.

LWCO LOW WATER Illuminates if the boiler is in a

low water condition. The Fuel Smart HydroStat will prevent

burner operation during this condition. IMPORTANT: The

system must be checked by a qualified heating professional

prior to resuming operation.

WARNING: DO NOT ADD WATER UNTIL THE BOILER

HA FULLY COOLED.

ECONOMY ACTIVE Indicates that the Thermal

Targeting function is active and the Fuel Smart HydroStat will

reduce boiler temperature to conserve fuel. The Economy

feature is activated using the ECONOMY dial. (See “How

Thermal Targeting Works” on page 4 for more information).

ECONOMY TARGET When the Economy feature is

active, the Fuel Smart HydroStat continually sets target

temperatures below the high limit setting to maximize fuel

efficiency. When the boiler water reaches the target

temperature, the LED illuminates and

the burner will shut down. The boiler

water will continue to circulate and

heat the house as long as the

thermostat call continues. The

LED will stay lit until the boiler

temperature drops to the differential

set point (see Target Temp Differential

on page 4) at which point the boiler

will be allowed to fire again. NOTE: This LED illuminates

regularly during normal boiler operation.

TE T/ ETTING Button

To Test Low Water Cut-Off: Press and hold the Test/

Settings button for 5 seconds. The display will read LCO.

LWCO TE T 00

The red Low Water light should illuminate and the burner

circuit (B1 and B2) should de-energize. NOTE: The control

must be installed with a Hydrolevel Electro-Well for low water

cut-off functionality (see page 2 for more details).

To View Current ettings: Press and release the

Test/Settings Button in short intervals to sequentially display

the following settings:

HIGH LIMIT ETTING 00

LOW LIMIT ETTING 00

ECONOMY ETTING 000

CURRENT TARGET TEMPERATURE

PRE-PURGE ETTING 000

The display will return to boiler temperature (default) if

Test/Settings Button in not pressed for 5 seconds.

LED LEGEND and TEST/SETTINGS BUTTON