3.1 Introduction

WARNING !

READ HEALTH AND SAFETY PRECAUTIONS

BEFORE YOU START ANY SERVICE WORK.

SERVICING OF THE COMPRESSOR MUST ONLY

BE CARRIED-OUT BY AUTHORISED PERSONS

FULLY TRAINED AND COMPETENT IN THE

MAINTENANCE, MAINS ELECTRICAL SUPPLY

AND STARTER CONTROL EQUIPMENT OF

HYDROVANE COMPRESSORS. THEY MUST

FULLY UNDERSTAND AND ADOPT CORRECT

AND SAFE WORKING PRACTICES.

Routine servicing should be carried out as instructed in the User

Handbook, ensure genuine parts are available for the following

tasks.

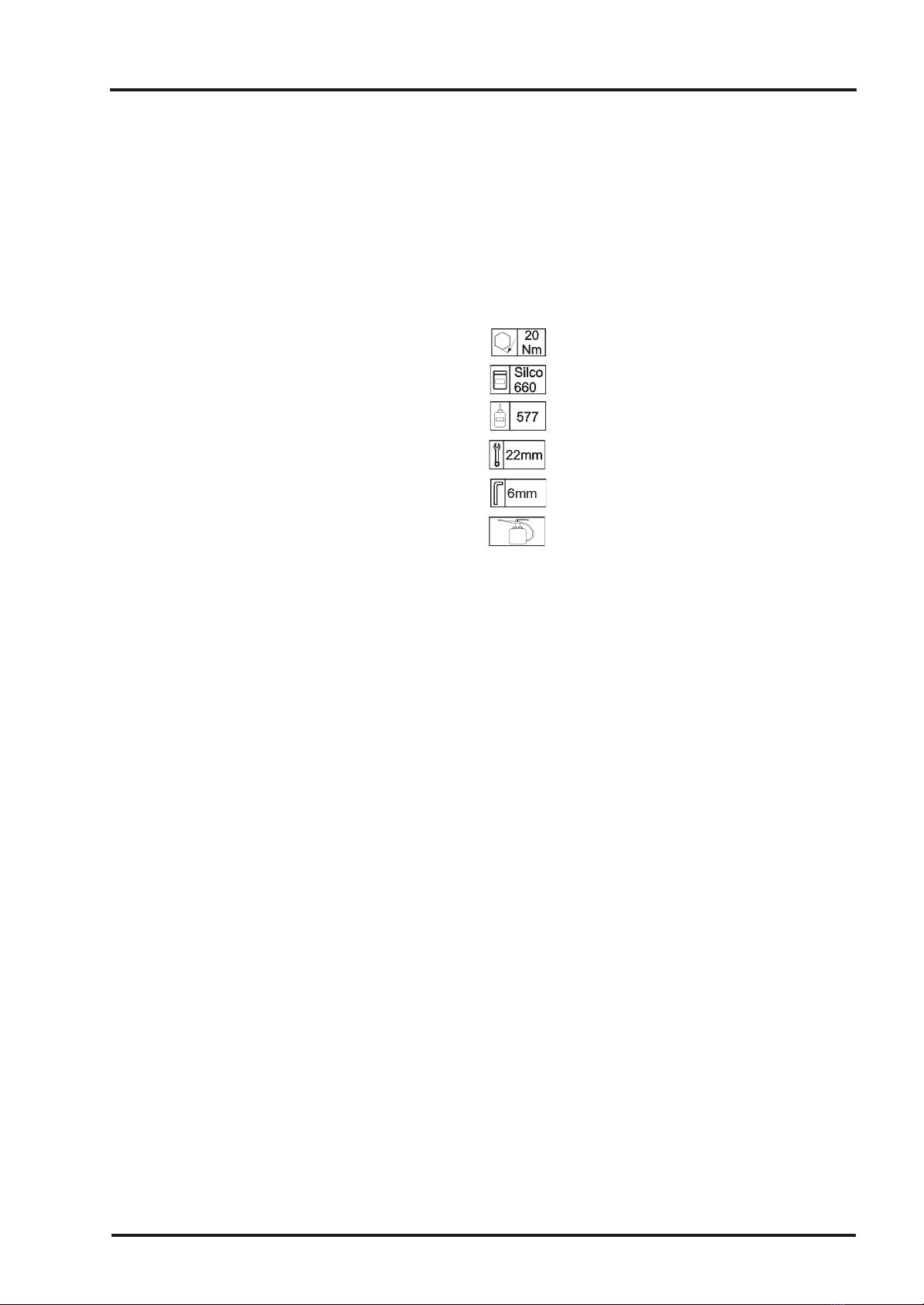

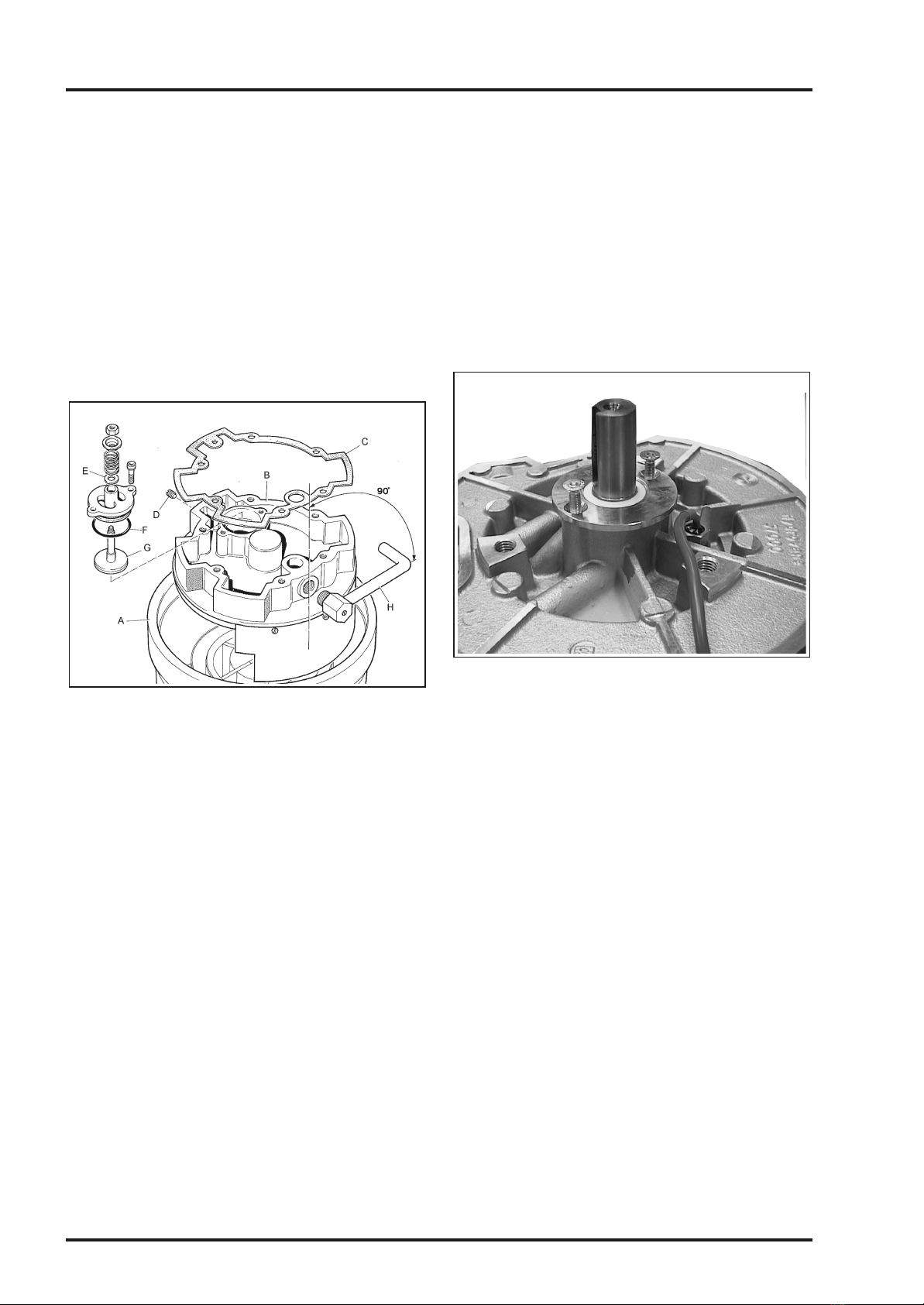

3.2 Minimum Pressure Valve (Fig 3.1)

Remove screws that retain the air filter cover to gain access to the

minimum pressure valve.

Renew bonded seal (A) and 'O' ring (B), apply silicon grease before

refitting.

Check piston ©) and valve (D) for wear or damage, renew if

necessary.

Clean filter (E) in white spirit or parafin, apply compressed air to

threaded end of filter, renew if it cannot be cleaned satisfactorily.

Testing of the minimum pressure valve is shown in Section 2.5.

3.3 Pressure Control Valve (Fig 3.2) PUTS/PUAS

Remove the screws that retain the valve cover plate.

Remove pressure control valves (F) and note settings, 7 or 10 bar

(100 psi or 145 psi), renew bonded seals (G)

Renew valves complete if found faulty, ensure new valves have the

same pressure rating as those removed. DO NOT attempt to adjust

or dismantle the valves

Testing of the pressure control valve is shown in Section 2.7

3.4 Safety Valve (Fig 3.2) PURS

Remove safety valve (H) renew bonded seal (G), replace valve if

found faulty, it cannot be dismantled or adjusted.

Testing of the safety valve is shown in Section 2.6

3.5 Oil Separator, Oil Return Valve (Fig 3.3)

Drain compressor oil, remove screws that retain the air filter cover.

Remove end cover (A) note its position relative to the separator

housing (F) for correct location on assembly, renew 'O' ring (B).

Unscrew oil separator ©) and examine, if contaminated or faulty, it

must be renewed, it cannot be cleaned

Renew the oil separator 'O' ring (D) and gasket (E)

Remove the separator housing (F) noting its position relative to the

oil chamber for correct location on assembly.

Renew 'O' ring (G) on separator housing (F), check restrictor plug

(H) in housing to ensure its orifice is clear.

Renew washer (J) on oil return valve (K), renew if contaminated,

replace washers (L) on housing bolts on re-assembly.

Refill compressor with FLUID FORCE RED 2000 or an APPROVED

OIL when assembly is complete.

ST16191-00A Page 5

3.0 Servicing hydrovane

Fig 3.1 - Minimum Pressure Valve

Fig 3.2 - Pressure Control and Safety Valves

Fig 3.3 - Oil Separator, Oil Return Valve