Catalogue

1.Brief introduction .................................................................................................................................3

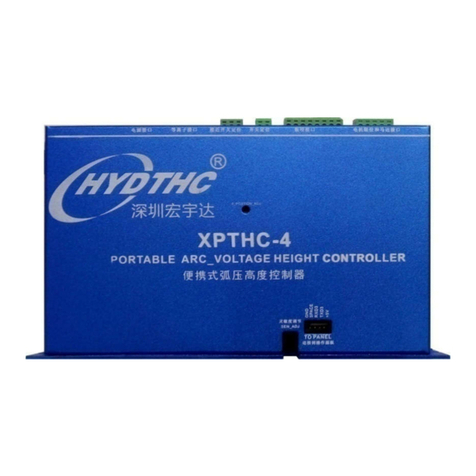

1.1 Introduction................................................................................................................................3

1.2 Performance Description...........................................................................................................4

2. Diagram introduction.............................................................................................................................5

2.1 components...............................................................................................................................5

2.2 installation size..........................................................................................................................6

2.2.1 main controller ..............................................................................................................6

2.2.2 preamplifier...................................................................................................................7

2.3 interface specification................................................................................................................8

2.3.1 interface layout.............................................................................................................8

2.3.2 power interface .............................................................................................................8

2.3.3 input and output interface..............................................................................................9

2.3.4 sensor interface ..........................................................................................................11

2.3.5 Application ..................................................................................................................12

3. Operation Introduce............................................................................................................................13

3.1 keyboard introduction..............................................................................................................13

3.2 Home page..............................................................................................................................13

3.3 Menu structure.........................................................................................................................14

3.4 Calibration interface.................................................................................................................15

3.5 Test menu ...............................................................................................................................16

3.6 Parameter menu......................................................................................................................16

3.6.1 Control parameters.....................................................................................................17

3.6.2 Advanced parameters.................................................................................................18

3.6.3 Alarm parameter .........................................................................................................19

3.6.4 Network parameter .....................................................................................................20

3.7 System parameters .................................................................................................................21

3.7.1 version information......................................................................................................21

3.7.2 Warning.......................................................................................................................22

3.7.3 Restart ........................................................................................................................22

3.7.4 Parameters Setting.....................................................................................................22

4. warning introduction............................................................................................................................23

4.1 warning introduce and reason.................................................................................................23

5.test introduction....................................................................................................................................25

5.1 Manual reference point (16 points) calibration........................................................................25

5.2 Automatic reference point (16 points) calibration....................................................................25

5.3 Adjust system and control parameters to optimize PID..........................................................27

6. Wiring introduction..............................................................................................................................28