Kelly KPM48401KD User manual

Other Kelly Controllers manuals

Kelly

Kelly KLS6045H User manual

Kelly

Kelly SPM4812S User manual

Kelly

Kelly KLS7250H User manual

Kelly

Kelly KDZ Series User manual

Kelly

Kelly KLS-S User manual

Kelly

Kelly Jaguar KLS8418N User manual

Kelly

Kelly KLS-H User manual

Kelly

Kelly KBS24051L User manual

Kelly

Kelly KLS11601-8080N User manual

Kelly

Kelly KLS6040S User manual

Kelly

Kelly KLS2418ND User manual

Kelly

Kelly KDHE Series User manual

Kelly

Kelly KLS-RM Series User manual

Kelly

Kelly KBL24101 User manual

Kelly

Kelly KLS11111-8080N User manual

Kelly

Kelly KLS72501-8080N User manual

Kelly

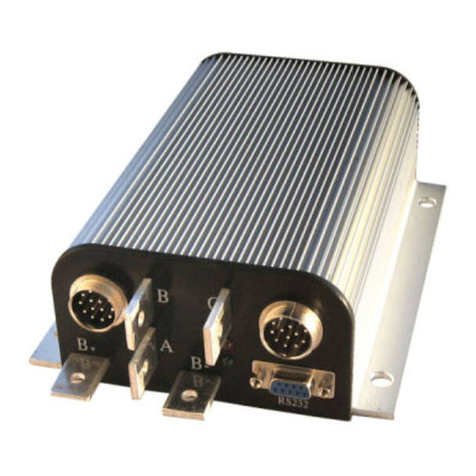

Kelly KDH72101E User manual

Kelly

Kelly KBL24101 User manual

Kelly

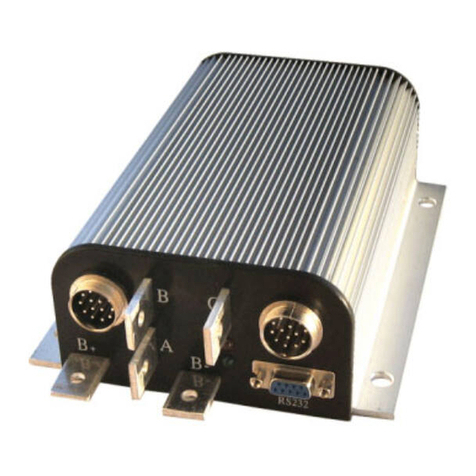

Kelly Jaguar KLS-N Series User manual

Kelly

Kelly Jaguar KLS9650NE User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions