--

---

•

O/lerating

Yourlxtractor

.8

When the extractor is installed the relevant speed can be selected to suit the ,specific

requirements.

Press the relevant button

in

to operate the function, press again to turn off.

A=LIGHTSwrrCH

B =

FIRST

SPEED

MOTOR

ONI

OFF

SWITCH

(This

switch

must

a/ways

be

on

for

second

&

third

speeds to operate).

C=

SECOND

SPEED

SWITCH

D=

THIRD

SPEED

swrtcH

E

==

WARNING

LIGHT

(MOTOR

ON)

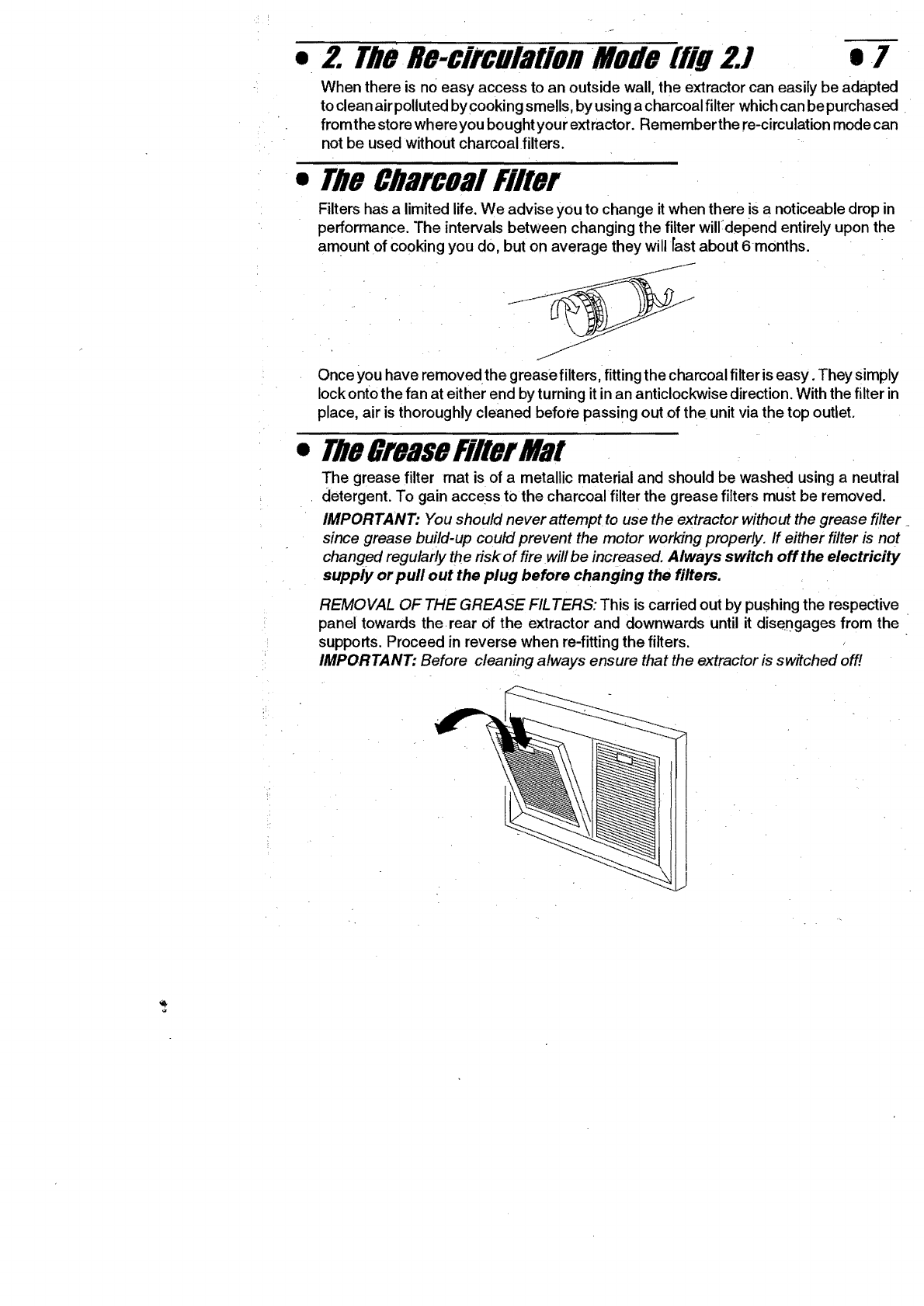

A.

B.

C.

D.

I.

66

6

•

Re/llacing

The

LightBulbs

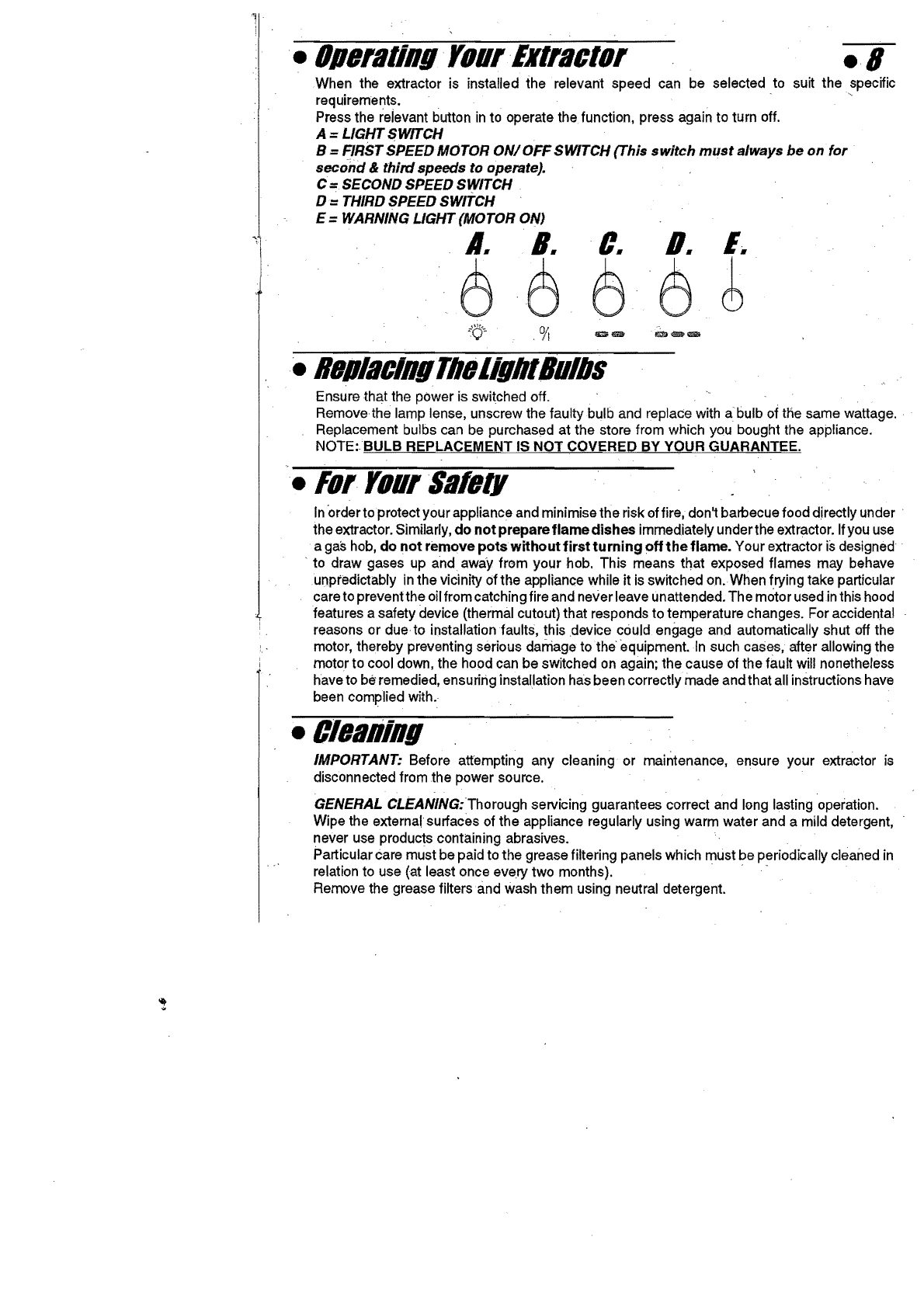

Ensure that the power is switched off.

Remove the lamp lense, unscrew the faulty bulb and replace with

abulb

of the same wattage.

Replacement bulbs can be purchased at the store from which you bought the appliance.

NOTE:

BULB

REPLACEMENT IS NOT COVERED BY YOUR GUARANTEE.

• lor

Your

Safety

In

orderto protect yourappliance and minimisethe risk offire, don'tbarbecue food directlyunder .

the extractor. Similarly,

do

not

prepare

flame

dishes

immediatelyunderthe extractor. Ifyou use

a gas hob,

do

not

remove

pots

without

first

tu

rning

off

the

flame.

Your extractor

is

designed

. to draw gases up

and

away fram your hob. This means that exposed flames may behave

unpredictably in the vicinity ofthe appliance while it is switched on.

When

frying take particular

caretopreventthe oilfromcatchingfire and neverleave unattended. Themotorused

in

this hood

features asafety device (thermal cutout) that responds to temperature changes. For accidental

reasons or due to installation faults, this .device could engage and automatically shut off the

motor, thereby preventing serious damage to the equipment.

In

such cases, after allowing the

motor

to

cool down, the hood can be switched on again; the cause of the fault will nonetheless

haveto beremedied, ensuring installation hasbeencorrectlymadeandthatall instructions have

been complied with.

•

Cleaning

IMPORTANT:

Before attempting any cleaning or maintenance, ensure your extractor

is

disconnected from the power source.

GENERAL

CLEANING:Thorough servicing guarantees correct and long lasting operation.

Wipe the external surfaces of the appliance regularly using warm water and a mild detergent,

never use products containing abrasives.

Particularcare must bepaid to the grease filtering panels which mustbeperiodically cleaned

in

relation to use (at least once every two months). . .

Remove the grease filters and wash them using neutral detergent.