2

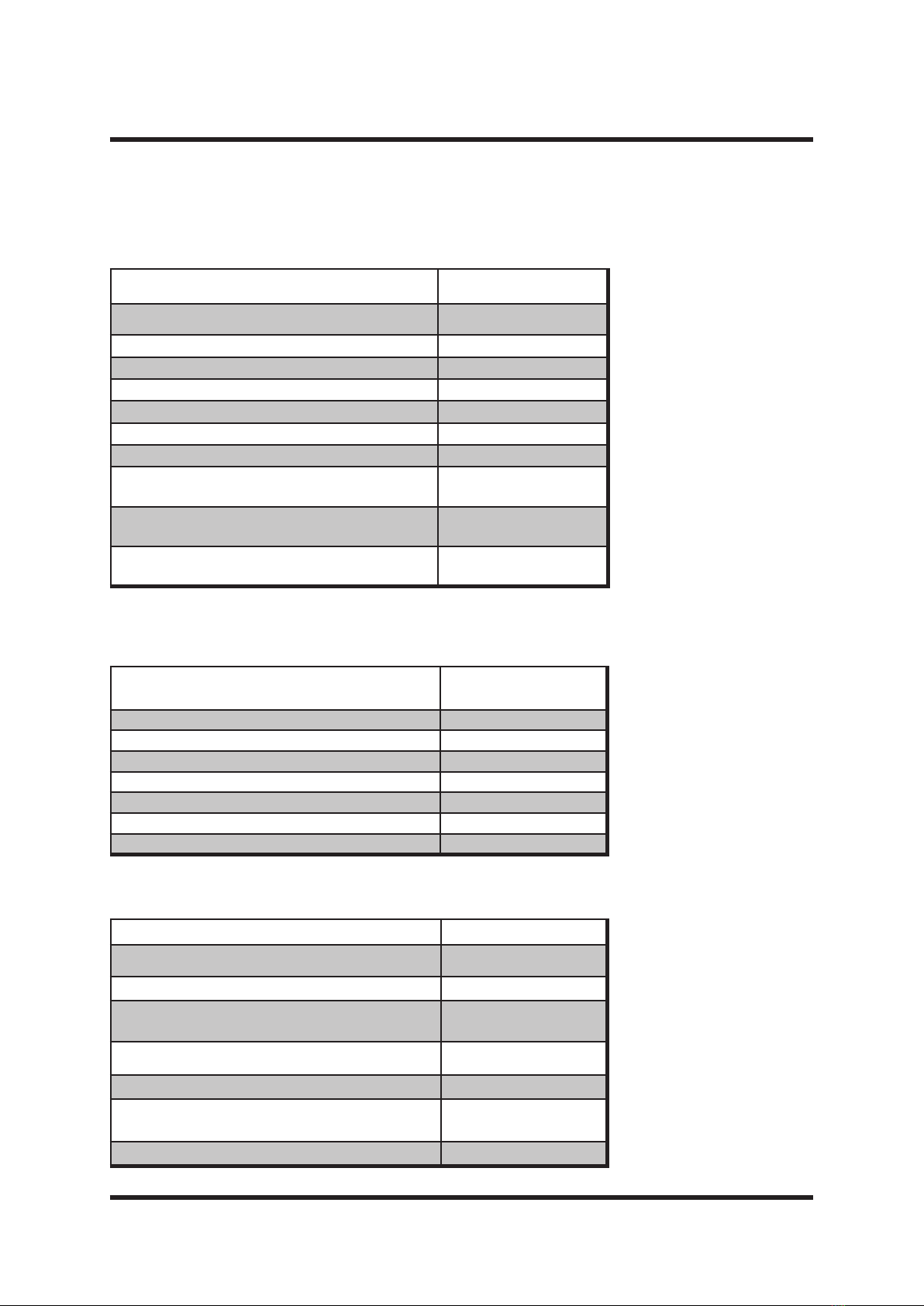

CONTENTS

FM-200® (UL/FM)

14A-07H

02

2010-03

SECTION 1 - INTRODUCTION

About this Manual . . . . . . . . . . . . . . . . . . 5

Definitions......................5

Contacts .......................5

Introduction .....................5

Approvals and Standards . . . . . . . . . . . . . . 5

FM-200®Agent..................6

Manufactured Systems . . . . . . . . . . . . . . 6

Health and Safety . . . . . . . . . . . . . . . . . . 6

FirstAid......................7

FM-200®Agent Characteristics . . . . . . . . . . . 7

Agent Physical Properties . . . . . . . . . . . . 8

Table1.......................8

Table2.......................8

Table 3: Toxicology/Environmental . . . . . . 8

SECTION 2 - SYSTEM COMPONENTS

System Components . . . . . . . . . . . . . . . . . 9

FM-200®Container. . . . . . . . . . . . . . . . 9

Table 4: DOT Container details . . . . . . . . 10

Table 5: UL/TPEDContainer details. . . . . . 10

Table 4a: DOT Container - valve equivalent

lengths.................... 10

Table 5a: UL/TPEDContainer - valve equivalent

lengths.................... 10

Container Label. . . . . . . . . . . . . . . . . 11

Valve Assembly . . . . . . . . . . . . . . . . 12

Principle of Operation . . . . . . . . . . . . . 13

BurstDisc.................... 13

Low Pressure Switch (Standard Open On Fall) 14

Low Pressure Switch (Special Close On Fall) 14

Low Pressure Switch (Alternate - Transfer On

Fall - Option #1). . . . . . . . . . . . . . . 15

Low Pressure Switch (Alternate - Transfer On

Fall - Option #1). . . . . . . . . . . . . . . 15

Fixing Brackets . . . . . . . . . . . . . . . . . 16

Manual Actuator . . . . . . . . . . . . . . . . 17

Pneumatic Actuator. . . . . . . . . . . . . . . 17

Removable Electrical Actuator (Suppression

Diode).................... 18

Removable Electrical Actuator (Bridge Rectifier)

........................ 18

25 mm (1") and 50 mm (2") Flexible Discharge

Hose..................... 19

80 mm (3") Discharge Hose/Check Valve

Assembly .................. 20

80 mm (3") Discharge Hose . . . . . . . . . . 20

80 mm (3") Valve Single Tank Adaptors . . . 21

Manifold Check Valve . . . . . . . . . . . . . 21

Manifold .................... 22

Table 6: Manifolds . . . . . . . . . . . . . . . 22

Table 6: Manifolds (Continued) . . . . . . . . 23

Manifold Inlets (Sockets) . . . . . . . . . . . 24

Table 7: Manifold Inlets . . . . . . . . . . . . 24

Construction of Manifolds . . . . . . . . . . . 25

Table 8: Manifolds . . . . . . . . . . . . . . . 25

Table 8: Manifolds (Continued) . . . . . . . . 26

Manifold Bracket Assembly . . . . . . . . . . 27

Flexible Pilot Hose . . . . . . . . . . . . . . . 27

Male Adaptors . . . . . . . . . . . . . . . . . 28

Male Pilot Hose Connector . . . . . . . . . . 28

StreetElbow .................. 29

MaleTee......................29

MaleElbow................... 30

Pressure Switch. . . . . . . . . . . . . . . . . 30

Discharge Nozzle. . . . . . . . . . . . . . . . 31

Table 9: Discharge Nozzles . . . . . . . . . . 32

DoorNotice................... 33

Manual Release Notice. . . . . . . . . . . . . 33

Liquid Level Measuring Device . . . . . . . . 34

Typical Manifold System . . . . . . . . . . . 35

SECTION 3 - SYSTEM DESIGN

SystemDesign................... 36

Hazard Analysis . . . . . . . . . . . . . . . . 36

Hazard Structure . . . . . . . . . . . . . . . . 37

Hazard Volume . . . . . . . . . . . . . . . . . 37

Ventilation ................... 38

Hazard Temperature . . . . . . . . . . . . . . 38

HazardFuels.................. 38

Personnel Safety . . . . . . . . . . . . . . . . 38

Agent Quantities . . . . . . . . . . . . . . . . 38

AgentStorage.................. 38

Manifolds.................... 39

Agent Distribution . . . . . . . . . . . . . . . 39

Agent Flow Characteristics . . . . . . . . . . . . 40

Nitrogen Superpressurisation . . . . . . . . . 40

FlowinPipe................... 40

Initial Vapour Discharge . . . . . . . . . . . . 40

Trailing Vapour Pressure. . . . . . . . . . . . 40

Nozzle Selection and Location. . . . . . . . . 40

Maximum Limits (Elevation) in Pipe Work. . 41

Nozzle Discharge Radius . . . . . . . . . . . 42

Example: Nozzle Selection. . . . . . . . . . . 42

System Design Procedure . . . . . . . . . . . . . 42

Example: Tee Split Designs . . . . . . . . . . 43

Design Example - Calculations . . . . . . . . . . 44

Example:.................... 44

Piping Practices . . . . . . . . . . . . . . . . . . 46