800.868.5987 / HYSIDE.COM /8

DEFLATING YOUR HYSIDE

The preferred way to deate your inatable is by deating all main chambers simultaneously, as this will help

avoid stress on any one bae (get a friend to help). You can then move on to deating the thwarts and oor.

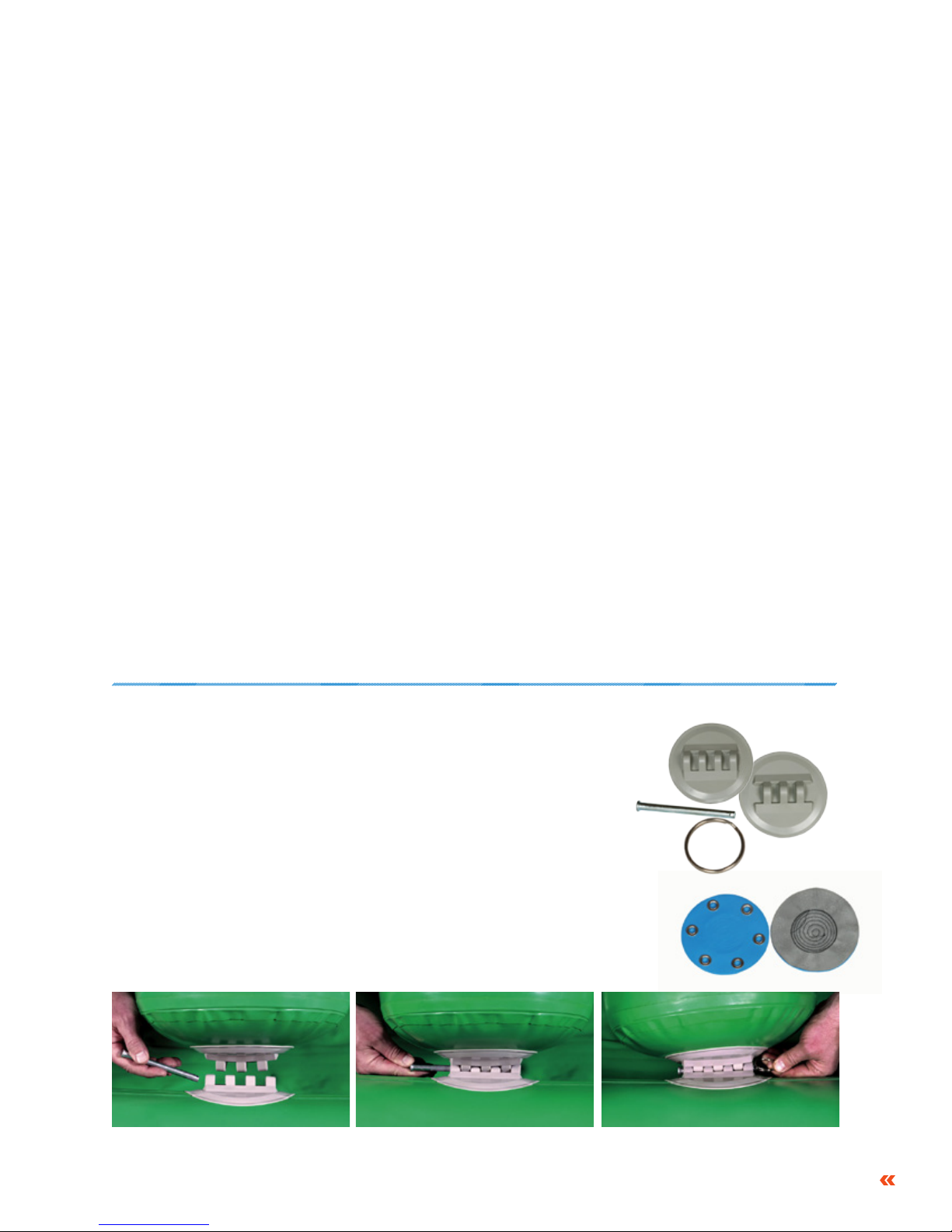

To set the valves for deation, simply push the valve stem in approximately 3/8” and turn it about ½ turn until it

locks in the open position. You can use the bottom side of a pump to suck the remaining air out of the chambers.

CLEANING YOUR HYSIDE

Keeping your inatable clean, especially prior to storage, will help prolong the life of your craft!

Sand and gravel can cause abrasion and plug air valves. If left to soak into an inatable boat, salt water can cause

the material to deteriorate.

You can use soap and water to clean your boat. For grimy messes, there are inatable cleaners on the market

that clean the surface and won’t harm it. Hypalon is very resistant to most chemicals, so the worst a heavy duty

cleaner can usually do is bleach the pigment, which doesn’t aect the Hypalon.

Use a largescrub padwith handle and work in four foot sections. Rinse the boat o with a power washer then spray

the cleaner on and wait ve minutes. Using a circular motion, scrub the area and then fully rinse immediately. The

boat will appear to be faded, but a coat of 303 Protectant will bring back the shine.

PROTECTING YOUR HYSIDE

We recommend 303 Protectant for your HYSIDE. Like sunscreen for your

boat, it protects against UV rays and it seems to work as a coating that doesn’t

allow dirt to adhere as much as if it weren’t there.

Originally intended by American Propeller Co to protect rubber and vinyl

airplane parts from high altitude UV, it is ideally suited for inatable protection.

Given that Hypalon is used to coat high power wires and reservoirs, it has

incredible UV resistance. We have found that 303 helps reduce pigment fading,

leaves a layer that is easier to clean o dirt and prolongs the life of the boat.

It is suggested that you apply 303 prior to storing your boats for the winter. Besides the fact that the boats will be

ready for use in the Spring and Summer, it can soften the areas that cause fold marks in some fabrics.

303 reacts to water, so polish until dry after applying to reduce the slippery eect.

Number of applications per year can vary, so to determine if it’s time for another application, rub some 303 on the

boat the size of a baseball. If it brings back the color to a noticeable degree, then it’s time for another application.

STORING YOUR HYSIDE

Removing Water

Preventing moisture during storage will greatly increase the lifespan of your boat.

Over time, moisture inside the tubes can break down the glue joints, so it needs to be removed promptly. The

obvious signs of trapped moisture are hearing it sloshing around or rubbing the two sides of a deated tube

together and if it feels slippery/slimey inside, you probably have old moisture inside (part of a routine inspection).

Removing the valve to the chamber is the rst step in cleaning it out. Use a pulley or turn the boat to the required

position and tie it o. The goal is to position the boat where you can get excess water to pool, then use ashop

vacwith a hose outside in the sunlight. Next, tape a ½ inch piece of PVC hose to the end of the hose and stick it

in the chamber, use this to remove all remaining pooled water. For the remaining moisture in the tubes, turn the

ACC-878

ACC-875