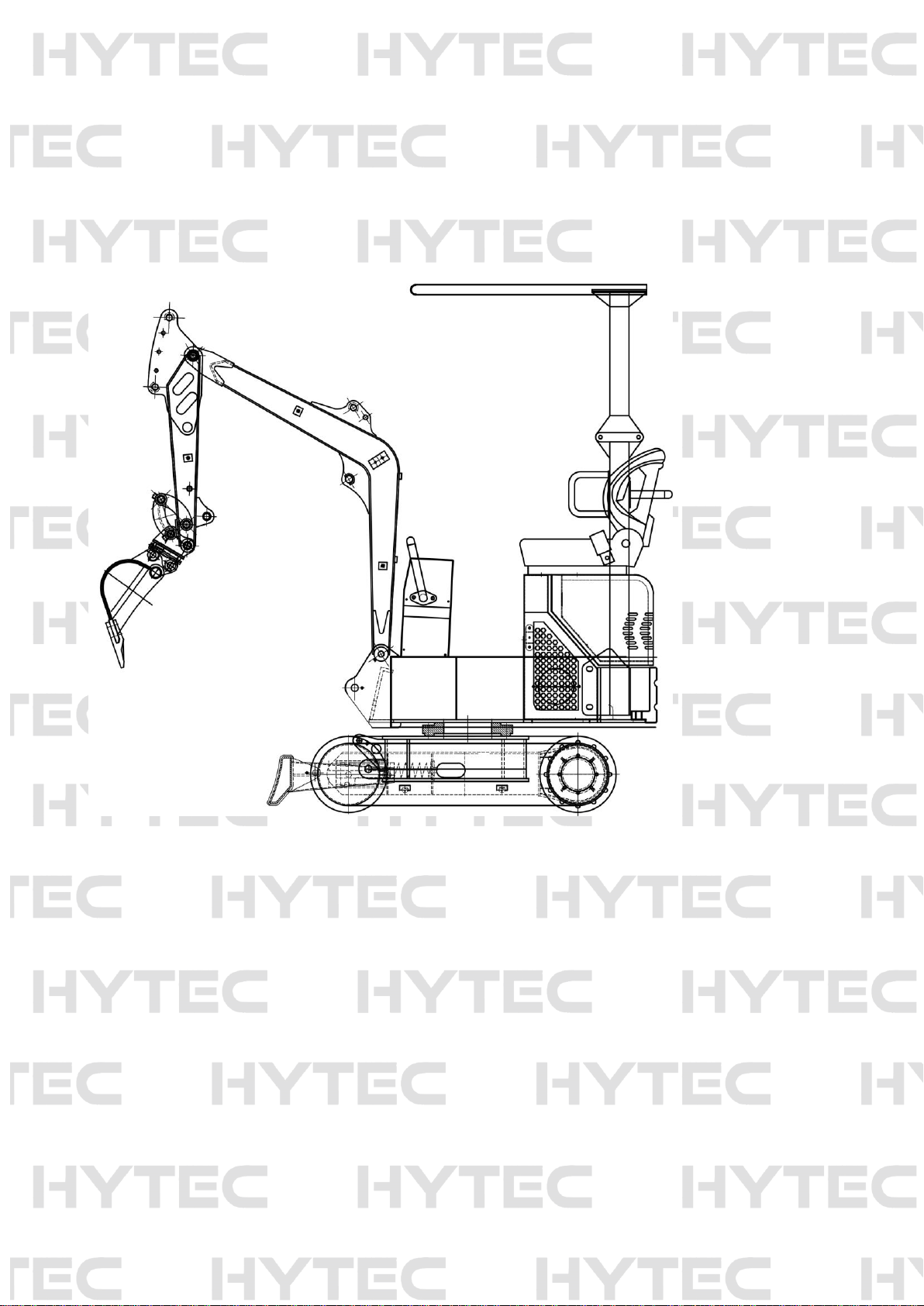

Section III Basic structure of HYTEC F1000 Excavator mechanical system

1

Power system

HYTEC F1000 Excavator is equipped with single-cylinder air-cooling diesel engine.

2

Drive system

HYTEC F1000 Excavator's drive system could transfer the output power from diesel engine through the hydraulic

system to work equipment, swing mechanism and travelingmechanism.

3

Swing mechanism

Swing mechanism could turn the work equipment and upper rotary leftwards and rightwards, so as to do the

excavating and the unloading. HYTEC F1000 Excavator’s swing mechanism has to fix the rotary table onto frame

and has it swing flexibly, without any inclining risk. Therefore, HYTEC F1000 Excavator is equipped with a

slewing support (supports) and a slewing drive (power of turntable slewing), which are called by a joint name as

swing mechanism.

3.1

Slewing support

HYTEC F1000 Excavator has its rotary table supported with a rolling bearing, realizing the swinging of

upper rotary.

3.2

Rotary drive

HYTEC F1000 Excavator adopts the direct drive type. Namely, the output shaft of low-speed high-torque

hydraulic motor is mounted with a driving pinion which meshes with the slewing gear ring. .

4

Travelingmechanism

Traveling mechanism supports the complete weight of excavator and drives it to run.

HYTEC F1000 Excavator has the crawler traveling mechanism similar to other crawlers, with one hydraulic motor

driving one track. This excavator adopts low-speed high-torque motor. When two hydraulic motors run in the

same direction, this machine goes straightly forward; when one motor is supplied with oil and the other is braked,

excavator steers around the braked track; when two motors runs reversely, excavator rotates in situ.

Each part of traveling mechanism is mounted on integral traveling frame. The pressure oil from hydraulic pump

goes through the multi-way directional valve and the central swing joint into the hydraulic traveling motor that

changes the pressure energy into output torque that then goes to sprocket, driving excavator to run.

HYTEC F1000 Excavator’s sprockets are of integral castings and able to correctly engage with track, featuring

balance drive. Sprockets located at rear part of excavator, shortening the tensioner part and relieving the track

abrasion, wear and power consumption. Each track is equipped with a tensioner, adjusting the track tension and

reducing the track vibration noise, abrasion, wear and power loss.

5

Work equipment

The hydraulic excavator could have multiple work equipment, up to dozens of varieties, with backhoe and ripper

most popular.

HYTEC F1000 Excavator has the boom, arm and bucket articulated with each other, as shown in figure and swing

around their articulated points respectively with aid of the hydraulic cylinder, finishing the excavating, lifting and

unloading.

5.1

Boom

As the main component of backhoe work equipment, the integrated skewed boom is adopted on HYTEC F1000

Excavator.

Being of the most popular type at present, skewed boom could allow excavator to dip deeper and to lower the

unloading depth, satisfying the backhoe requirements.