Table of contents

Notes concerning this manual and the manufacturer ............................................6

Keep the manual available .............................................................................................6

Design features of this manual.......................................................................................6

Referenced documents...................................................................................................7

Manufacturer's address ..................................................................................................7

Person responsible for documentation...........................................................................8

Warranty and liability ......................................................................................................8

Safety........................................................................................................................9

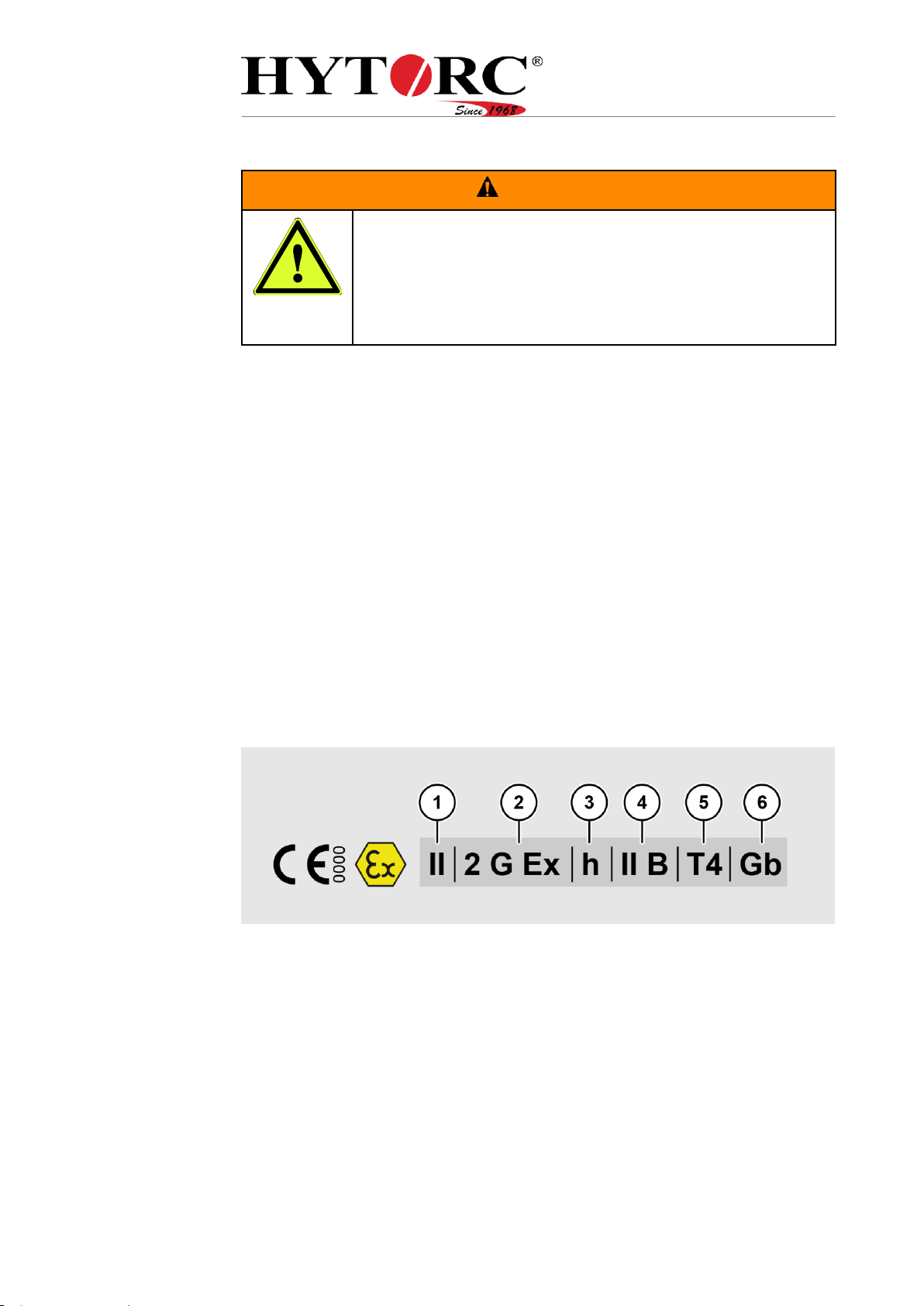

ATEX marking.................................................................................................................9

Equipment group (1).............................................................................................9

Equipment category (2)......................................................................................10

Ignition protection type (3)..................................................................................10

Explosion group (4) ............................................................................................10

Temperature class (5) ........................................................................................10

Equipment protection level (6)............................................................................11

ATEX marking of the unit....................................................................................11

Responsibilities of the operating company...................................................................11

Persons at particular risk..............................................................................................12

Qualification of personnel.............................................................................................12

Connecting the Compressed Air Supply ............................................................12

Tool connection ..................................................................................................12

Setting pressure/torque......................................................................................13

Assessing the state of the unit ...........................................................................13

Carrying the unit .................................................................................................13

Ban of unauthorized conversions .................................................................................14

Personal protective equipment.....................................................................................14

Basic safety information................................................................................................15

Preventing serious injury or death......................................................................15

Preventing explosion hazards ............................................................................15

Preventing burns from oil and hot surfaces........................................................15

Preventing poisoning..........................................................................................15

Preventing bone fractures and crushing.............................................................16

Preventing eye damage......................................................................................16

Preventing skin irritation.....................................................................................16

Preventing material damage ..............................................................................16

Intended use.................................................................................................................17

Ambient conditions .......................................................................................................17

Design characteristics of warning information..............................................................18