Brushless Motor Driver SEH400RB

Catalogue

1 Brief Instruction ...........................................................................................................................................2

1.1 Features ................................................................................................................................................2

2.1 Electrical Performance .........................................................................................................................2

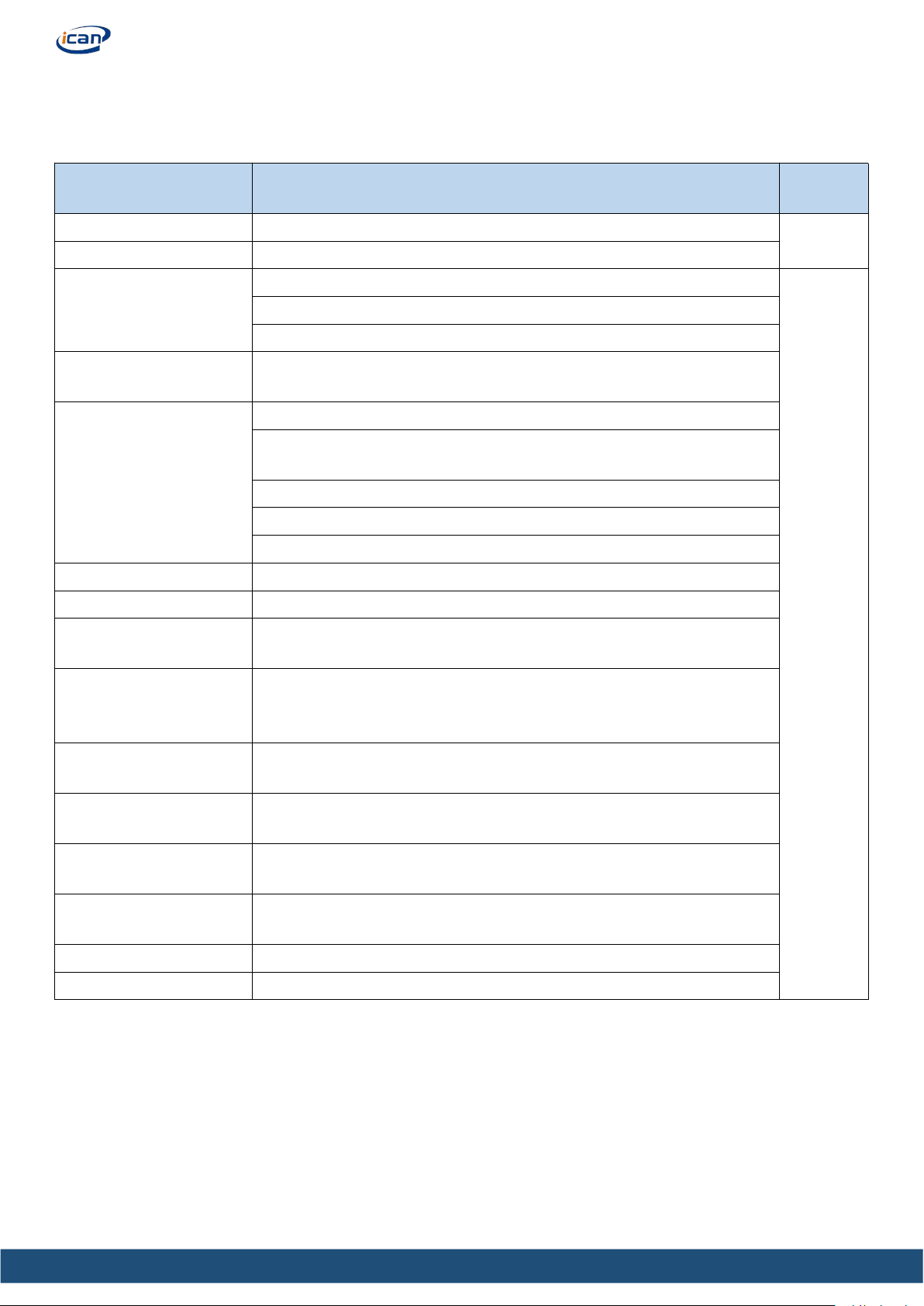

4 Driver port and function description ...............................................................................................................3

4.1 Driver port ............................................................................................................................................3

4.2 Terminal Description ........................................................................................................................... 4

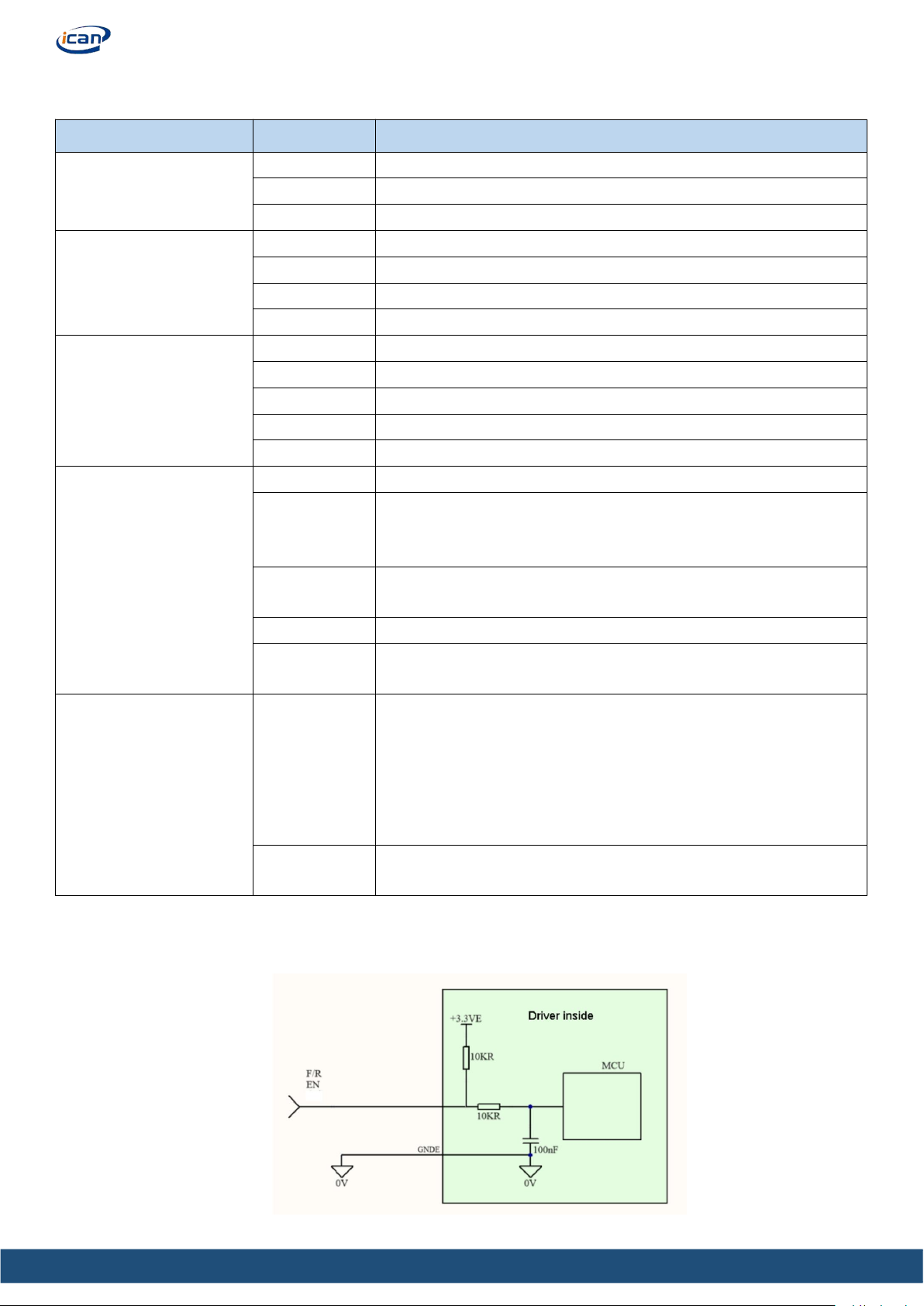

4.3 Description of external control signal circuit ...................................................................................... 4

4.4 Output circuit description .................................................................................................................... 5

5 Introduction to panel functions ....................................................................................................................... 6

5.1Panel functions ......................................................................................................................................6

5.2 Panel introduction ................................................................................................................................ 7

6.1 Start and stop ....................................................................................................................................... 9

6.2 Direction control. ................................................................................................................................. 9

6.3 Speed regulation mode. ........................................................................................................................9

6.4 RS485 .................................................................................................................................................11

7.2ALARM RESET .................................................................................................................................15

8 Troubleshooting ............................................................................................................................................ 15

After Sales Service ...........................................................................................................................................16