Table of Contents

Safety Guide.................................................................................................................1

1. Safety Precautions ..........................................................................................9

2. Warranty ..............................................................................................................10

2.1 Warranty Period .................................................................................................................10

2.2 Scope of the Warranty .......................................................................................................10

2.3 HonoringtheWarranty .......................................................................................................10

2.4 Limited Liability....................................................................................................................11

2.5 Conditions of Conformance with Applicable Standards/Regulations, Etc.,

and Applications..................................................................................................................11

2.6 Other Items Excluded from Warranty..................................................................................11

3. Application Environment .....................................................................................12

4. Functions and Specications of Teaching Pendant ..............................................13

4.1 Specications ......................................................................................................................13

4.2 External View .....................................................................................................................14

4.3 Description of Each Part .....................................................................................................15

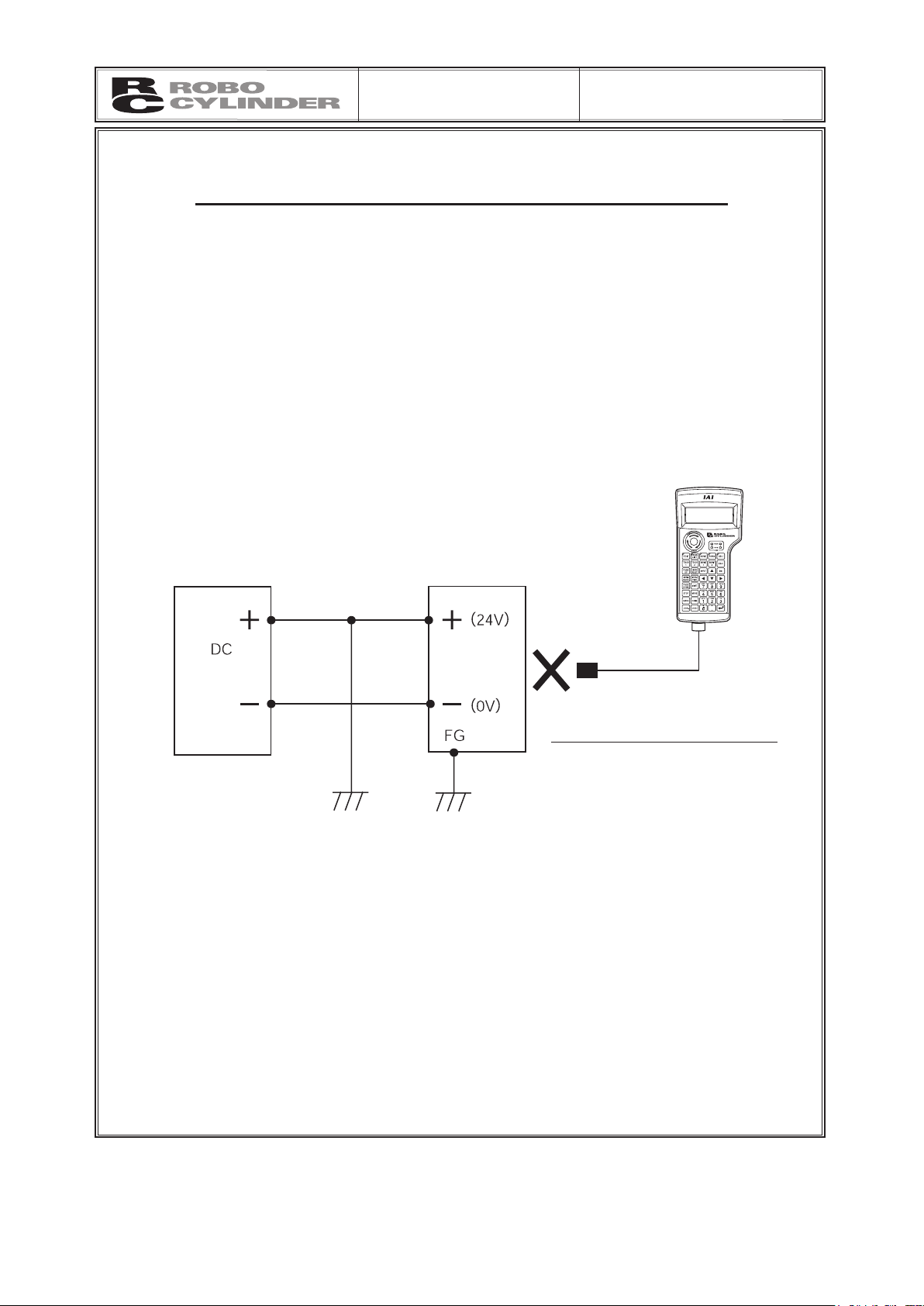

5. Connection With the Controller............................................................................20

5.1 Connection with the Teaching Pendant ..............................................................................20

5.2 HowtoDisengagetheTeachingPendant...........................................................................20

5.3 Connection between CON-TG/TGS and the Controller ......................................................21

6. Operation: Mode Flow Chart................................................................................27

(1) Positioner (PCON-PL/PO, ACON-PL/PO and SCON:

Mode other than the Pulse Train Mode).............................27

(2) Pulse Train (PCON-PL/PO, ACON-PL/PO and SCON: Pulse Train Mode) ............................28

6.1 Initial Screen and TP Operation Mode Screen During Power - UP ....................................29

6.2 Controller Selection (when using multiple units) ................................................................31

6.3 Operation Mode Selection ..................................................................................................32

6.4 Edit/Teaching .....................................................................................................................33

6.4.1 PCON, ACON, SCON, DCON, ERC2 or ERC3 ………………………………………… 33

6.4.2 RCP, RCS, E-Con or RCP2 ……………………………………………………………… 35

6.5 Position Data Table Contents ............................................................................................37

6.5.1 Position Data Table Contents for PCON, ACON, SCON, DCON, ERC2 or ERC3 … 37

6.5.2 Position Data Table Contents for RCP, RCS, E-Con and RCP2 …………………… 44

6.5.3 Data New Input……………………………………………………………………………… 46

6.5.4 DataModication …………………………………………………………………………… 64

6.5.5 Clear All Clear …………………………………………………………………………… 64