Contents

I. Abbreviations .................................................................................................5

II. Control panel .................................................................................................5

III. Software version .............................................................................................6

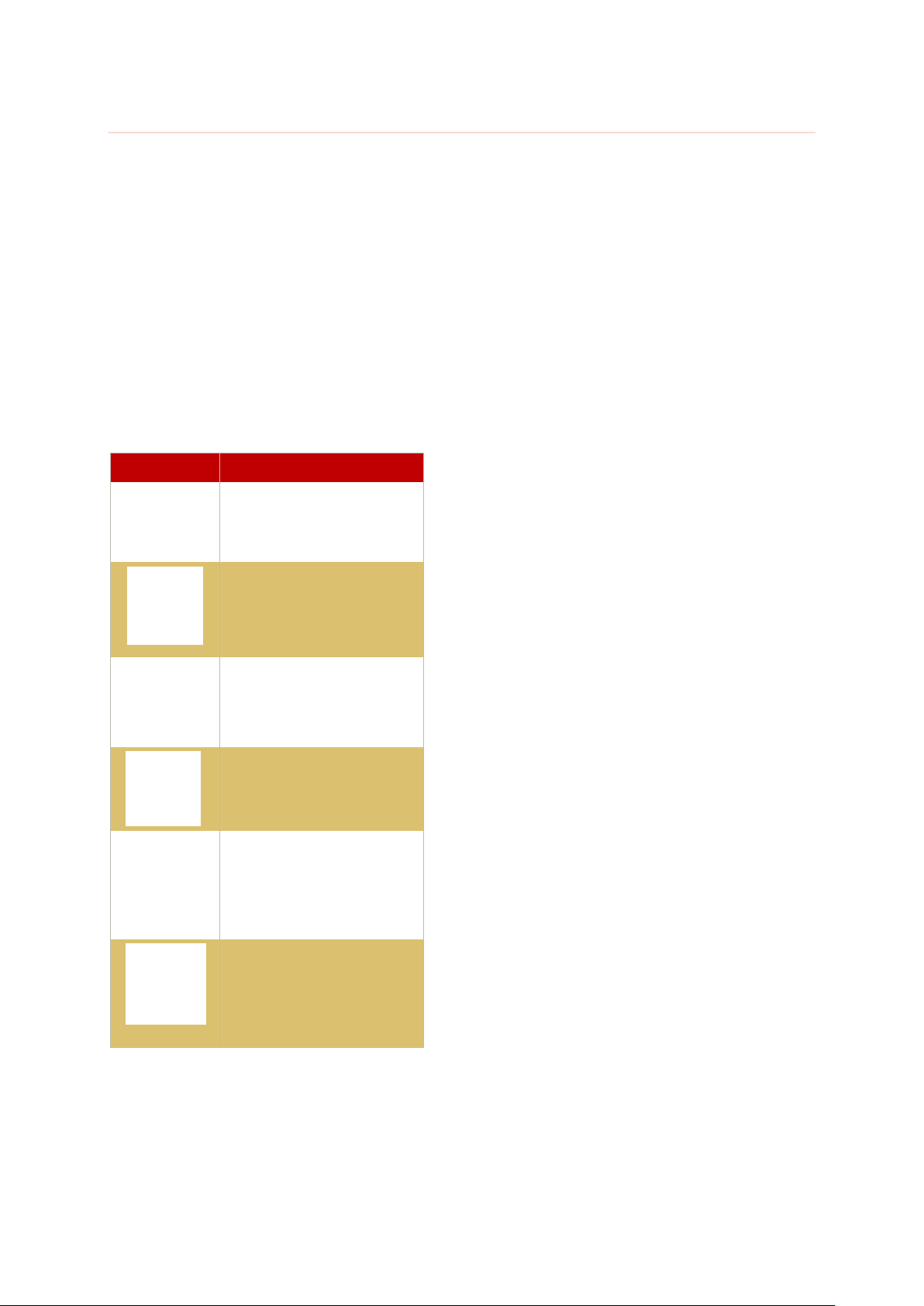

IV. Thermostats, Probes, Solenoids and Pressure Switches positions...............7

V. Functions ......................................................................................................11

STOP ........................................................................................................................................................11

Resetting to zero the hour counter MA –MP .................................................................................................11

Resetting to zero of the total and partial hours counter.................................................................................11

Event log.................................................................................................................................................................12

PRODUCTION.....................................................................................................................................13

Cylinder ...................................................................................................................................................................13

Cabinet.....................................................................................................................................................................15

STORAGE ..............................................................................................................................................18

DEFROST...............................................................................................................................................19

Automatic Defrost ................................................................................................................................................19

Safety Defrost.........................................................................................................................................................19

VI. Cleaning / Load / Calibration pump tubes................................................ 21

Calibration of the pump tubes..............................................................................................................21

Hour counter MA and MP....................................................................................................................24

VII. Wash Days ................................................................................................... 25

VIII. Keypad Locked ............................................................................................ 26

IX. Alarms .......................................................................................................... 27

Power ON................................................................................................................................................31

X. Autosetup ..................................................................................................... 32

XI. List of events................................................................................................ 33

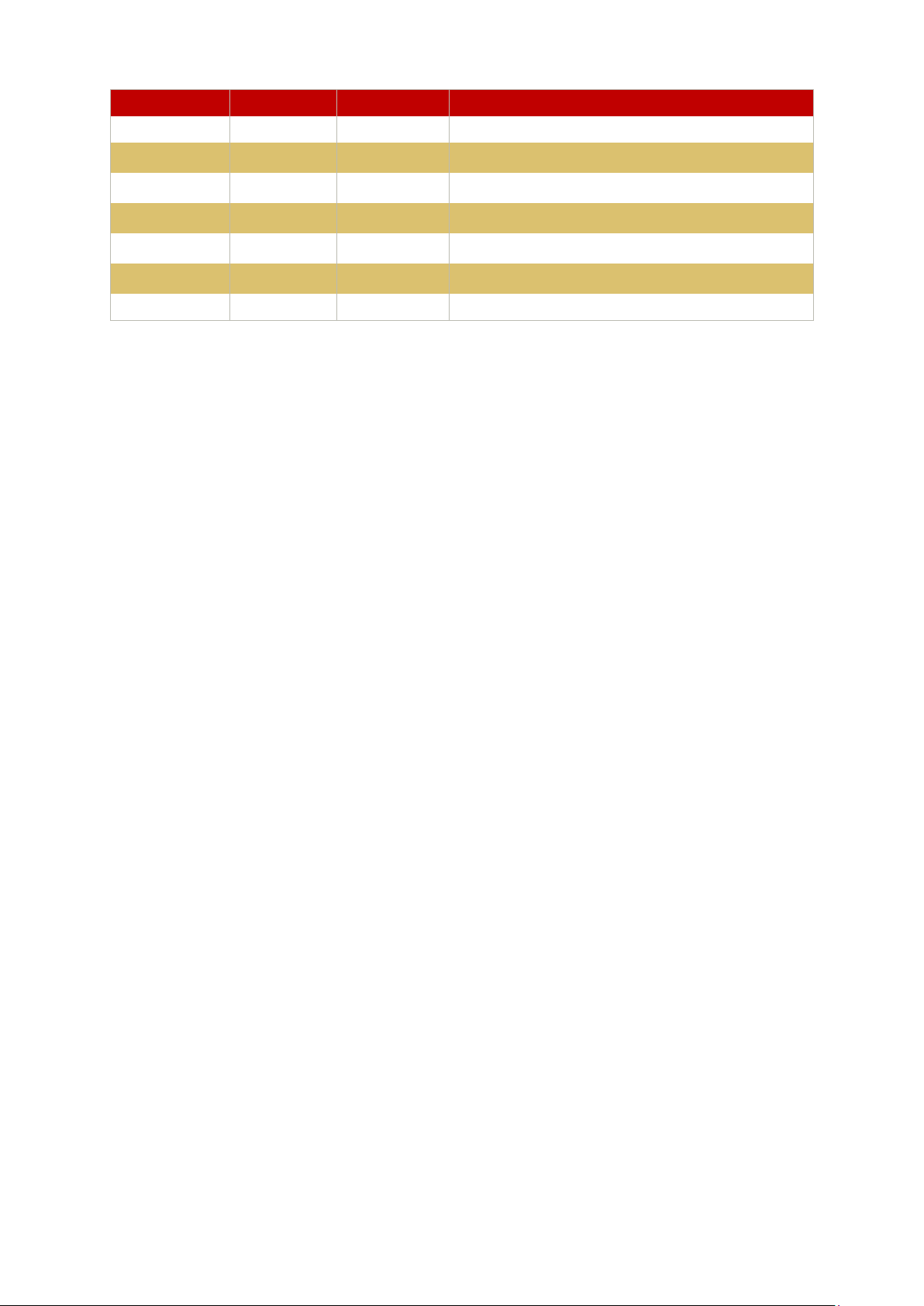

XII. Programming Table (FOR USERS) ........................................................... 34

XIII. Programming Table (FOR TECHNICIANS)............................................ 36

XIV. HOT CALIBRATION ................................................................................ 43

XV. View of electronic boards ............................................................................ 44

XVI. Jumper IC573700148 .................................................................................... 45

XVII. Control unit replacement/software upgrade .............................................. 46

Control unit replacement.......................................................................................................................46

Software upgrade ....................................................................................................................................46

XVIII. Software updates.......................................................................................... 47