General information8

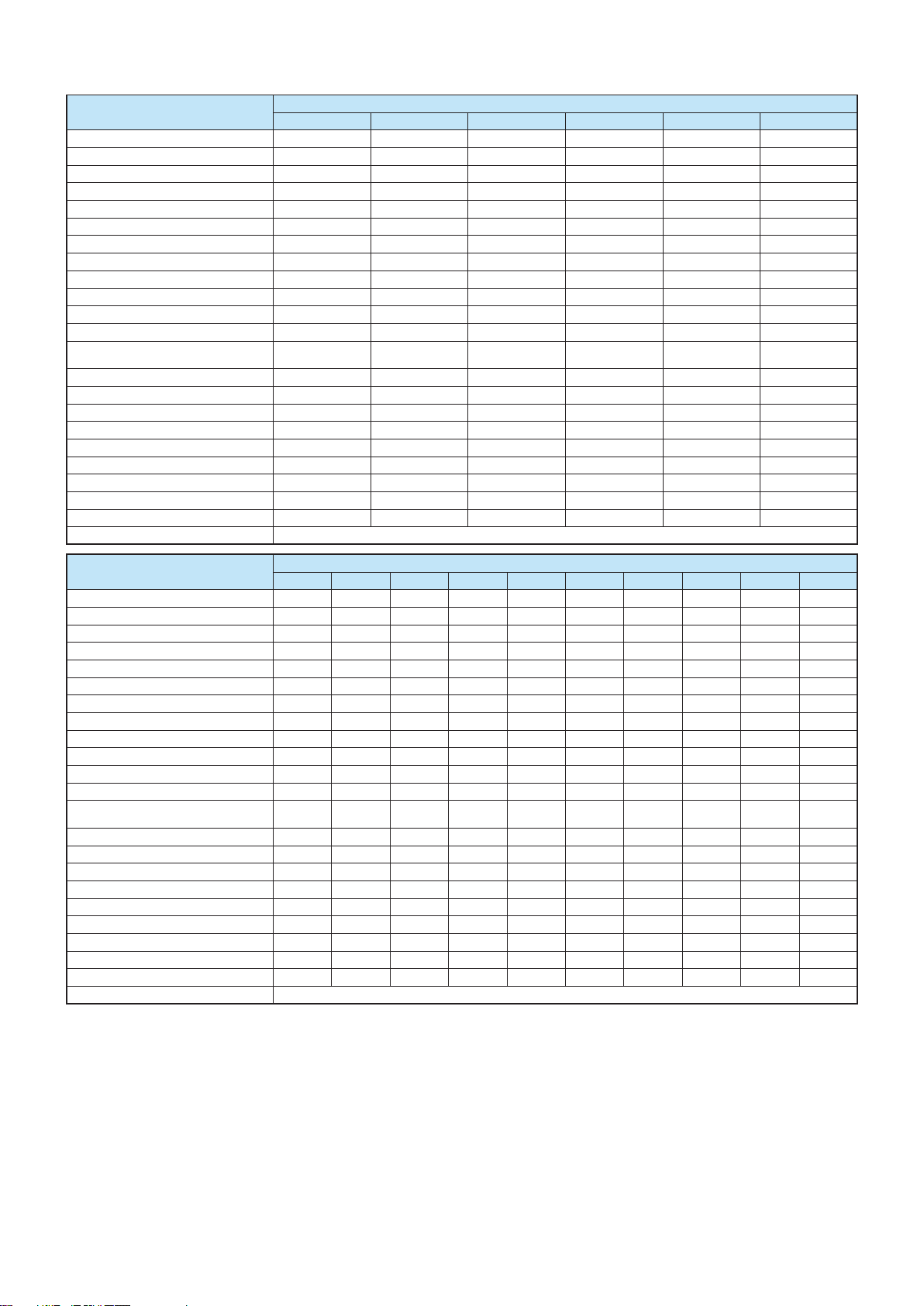

TECHNICAL DATA

DESCRIPTION u.m. ASGX EN

3000 3500 4000 5000 6000 7000

Nominal power

kW 3000 3500 4000 5000 6000 7000

Thermal capacity

kW 3333 3888 4444 5555 6666 7777

100% efficiency (ref. NCV)

% 90 90 90 90 90 90

NG max flow rate G20

Stm3/h 352,65 411,47 470,28 587,92 705,43 822,94

NG max flow rate G30

kg/h 261,74 305,39 349,04 436,35 523,56 610,78

NG max flow rate G31

kg/h 258,9 302,08 345,26 431,62 517,89 604,16

Max flue gas flow rate

kg/h 5254,49 6130,9 7007,17 8760,01 10510,91 12261,81

100% efficiency (ref. NCV)

% 92 92 92 92 92 92

Pressure drop

mbar 15 18 15 20 13 15

Heat losses through the chimney

% 9,7 9,7 9,7 9,7 9,7 9,7

Heat losses through the casing

% 0,3 0,3 0,3 0,3 0,3 0,3

Heat losses with burner off

% 0,1 0,1 0,1 0,1 0,1 0,1

Flue gas temp. at boiler output and air

at 20 deg. C

°C 240 240 240 240 240 240

CO

2% 10 10 10 10 10 10

Hydraulic pressure drop

mbar 55 75 98 154 91 123

Rated pressure

bar 12 12 12 12 12 12

Total capacity

l 4520 5300 6650 8600 9150 10200

Total weight

kg 7000 7800 9000 11000 13000 14500

Electric supply

Volt ~ 230 230 230 230 230 230

Frequency

Hz 50 50 50 50 50 50

Insulation class

IP IP55 IP55 IP55 IP55 IP55 IP55

Electric power

W 1000 1000 1000 1000 1000 1000

Allowed fuels

Methane - LPG - Diesel - Naphtha

DESCRIPTION u.m. ASGX EN

8000 9000 10000 11000 12000 13000 14000 15000 16000 17000

Nominal power

kW 8000 9000 10000 11000 12000 13000 14000 15000 16000 17000

Thermal capacity

kW 8791 9890 10989 12087 13157 14285 15384 16339 17486 18681

100% efficiency (ref. NCV)

% 91 91 91 91 91,2 91 91 91,8 91,5 91

NG max flow rate G20

Stm3/h 930,23 1046,51 1162,91 1279,19 1392,4 1511,75 1628,03 1729,05 1850,38 1976,87

NG max flow rate G30

kg/h 690,41 776,71 863,11 949,41 1033,42 1122,01 1208,31 1283,29 1373,33 1467,21

NG max flow rate G31

kg/h 682,93 768,29 853,75 939,11 1022,22 1109,85 1195,21 1269,38 1358,45 1451,31

Max flue gas flow rate

kg/h 13860,43 15593 17327,36 19059,93 20746,76 22525,08 24257,65 25762,85 27570,66 29455,36

100% efficiency (ref. NCV)

% 93 93 93 93 93,2 93 93 93,8 93,5 93

Pressure drop

mbar 17,5 22,5 15 19 22 26 23,5 19,5 22 23

Heat losses through the chimney

% 8,7 8,7 8,7 8,7 8,5 8,7 8,7 7,9 8,2 8,7

Heat losses through the casing

% 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3

Heat losses with burner off

% 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1

Flue gas temp. at boiler output and air

at 20 deg. C

°C 212 212 212 212 208 212 212 195 201 212

CO

2% 10 10 10 10 10 10 10 10 10 10

Hydraulic pressure drop

mbar 161 98 66 79 94 111 128 86 98 111

Rated pressure

bar 12 12 12 12 12 12 12 12 12 12

Total capacity

l 14950 16200 20200 20200 21800 21800 23800 33000 33000 35100

Total weight

kg 15400 16300 24940 24940 25400 25400 28050 37500 37500 45000

Electric supply

Volt ~ 230 230 230 230 230 230 230 230 230 230

Frequency

Hz 50 50 50 50 50 50 50 50 50 50

Insulation class

IP IP55 IP55 IP55 IP55 IP55 IP55 IP55 IP55 IP55 IP55

Electric power

W 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

Allowed fuels

Methane - LPG - Diesel - Naphtha

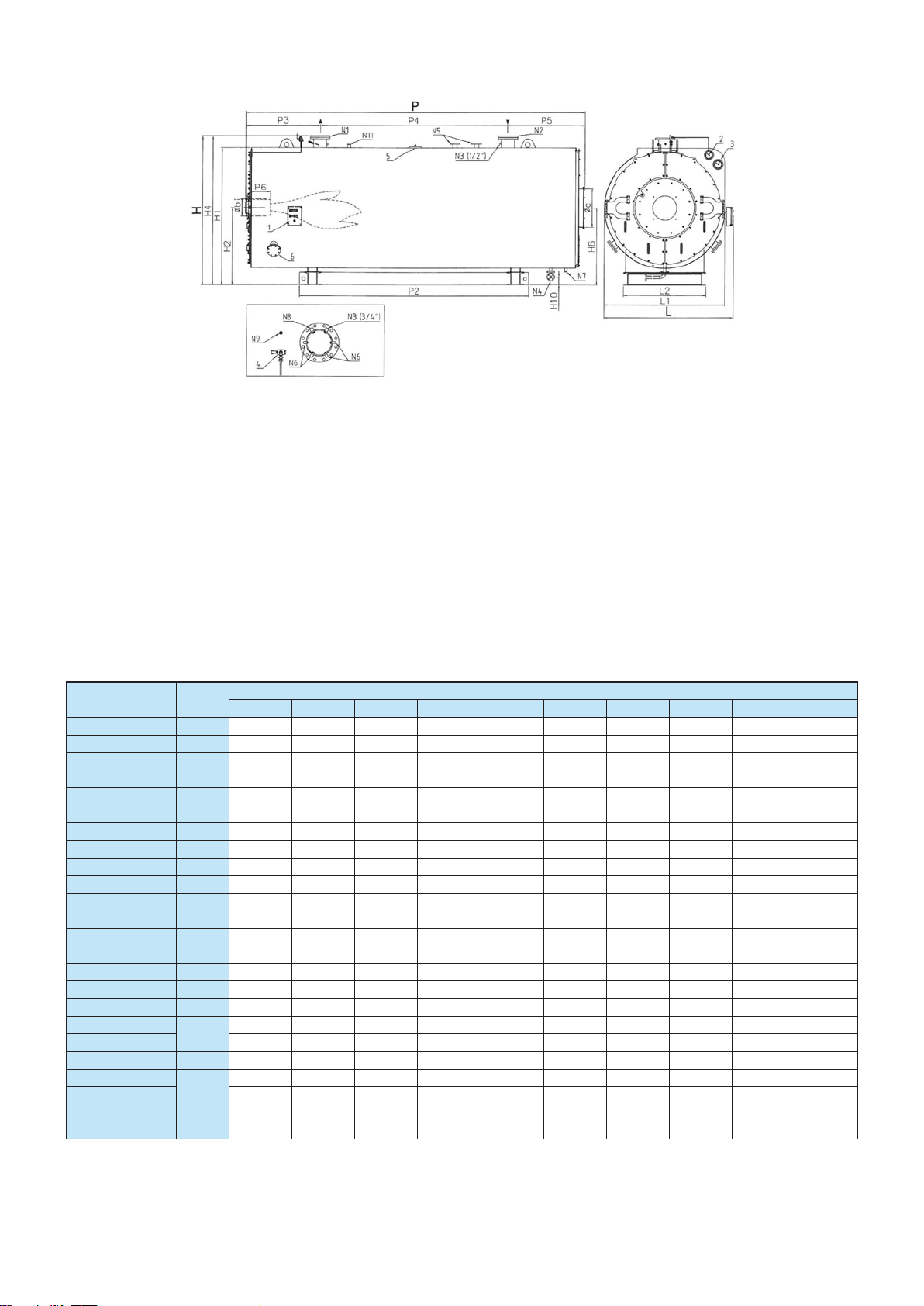

Water delivery ΔT max 30°C

Design data

Minimum/maximum temperature

-10°C / 191,7 °C

Cooke

Industries

-

Phone:

+64

9

579

2185

Email:

[email protected] Web:

www.cookeindustries.co.nz