Page 2 For technical questions, please call 1-888-866-5797. 57923

Specifications

Torque Range 40-250 ft-lb

Drive

Accuracy ±4% CW

Important Safety Information

WARNING Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in injury.

Save all warnings and instructions for future reference.

1. The warnings, cautions, and instructions

in this instruction manual cannot cover all

possible conditions and situations that may

occur. It must be understood by the operator

that common sense and caution are factors

which cannot be built into this product,

but must be supplied by the operator.

2. Wear ANSI-approved safety

goggles during use.

3. Do not use for loosening fasteners.

4. Use only within rated torque range.

5. Use as intended only. Do not

use as hammer or pry bar.

6. Do not use handle extension to increase

force. Do not use as a breaker bar.

7. Do not use a Torque Wrench that

has been dropped. Have it tested

before putting back into use.

8. Have the Torque Wrench calibrated and

serviced only by a qualified technician.

9. Inspect before every use; do not use

if damaged or if parts are loose.

10. Keep away from children.

11. Use only sockets with the correct

drive and rated to at least the

torque that will be applied to it.

Operating Instructions

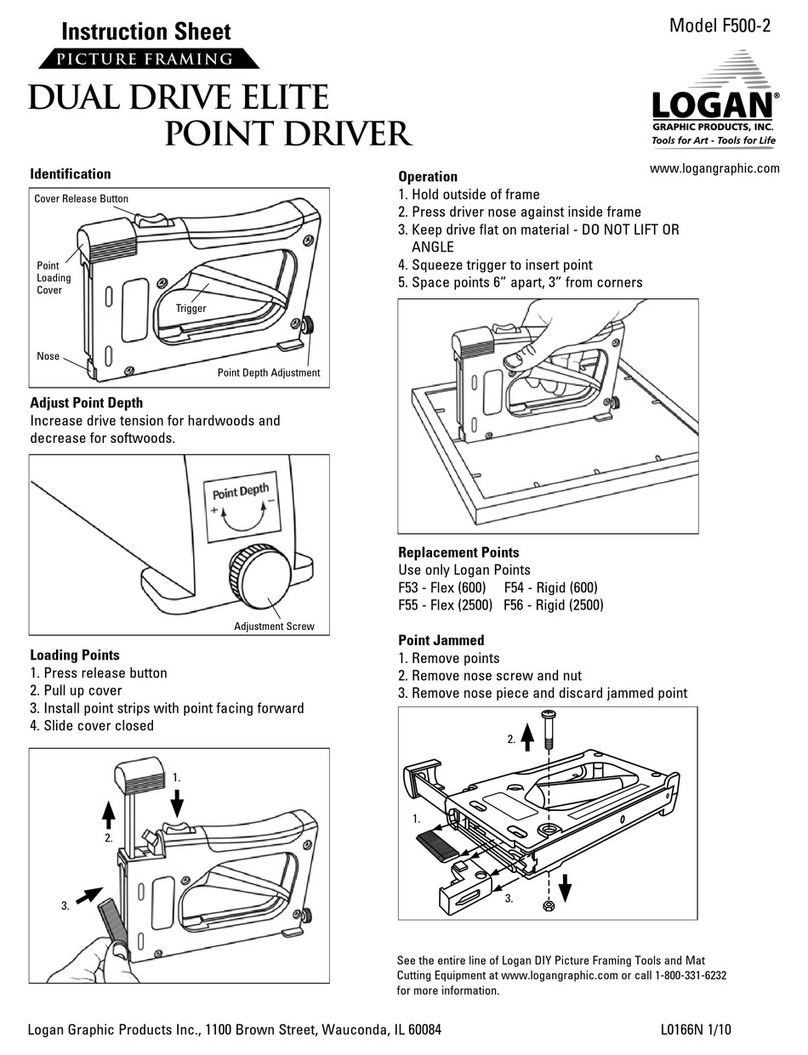

Torque

Scale

Ratchet

Head Rubber Grip

Lock & Unlock

Latch

CAUTION! Wear ANSI-approved

safety goggles during use.

Note: The Torque Scale is marked with

Foot Pounds. Scale below index line converts

Foot Pounds to Newton Meters. The following

instructions illustrate setting torque value properly

1. BEFORE EVERY USE, exercise Torque

Wrench. Open latch to unlock torque knob

(see step 5 on page 3), then perform

the following exercise three times:

a. Turn Handle to the right until maximum

torque setting is reached.

b. Turn Handle to the left until minimum

torque setting is reached.