Savannah™ VG - XL VG AIRPLANE

MAINTENANCEMANUAL

ICP Srl –S.P.16 km 15,150-14022 Castelnuovo Don Bosco (AT)

Phone +39-0119927503 •Fax +39-0119927266

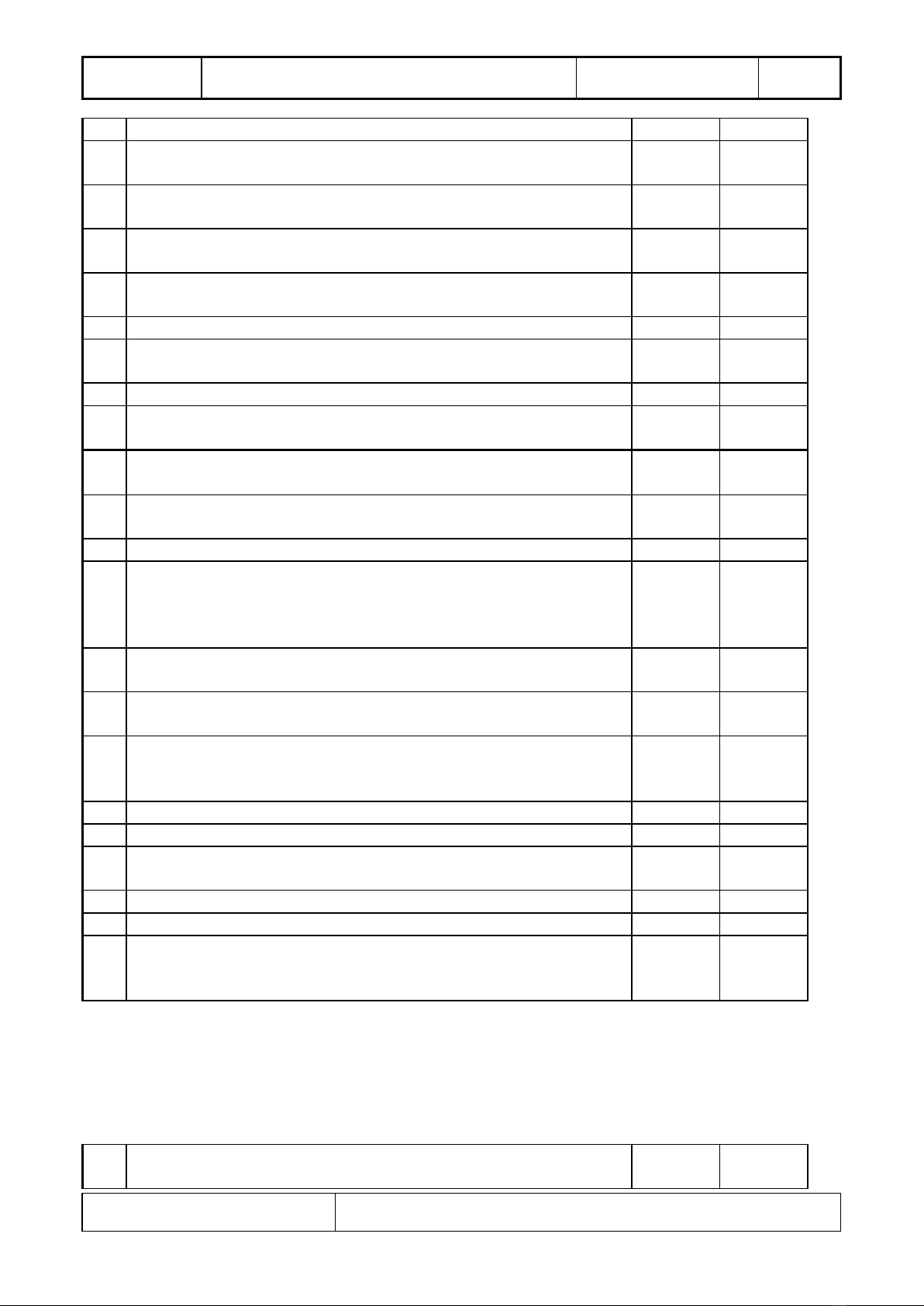

the hook is locked, the control cable for condition

Check the electric wires for condition, routing and security; check

the anti-collision lights control box for condition, if installed

Check the flaperon and elevator springs for security; adjust if

required

Visually inspect the fuselage interior; close the inspection panel at

the fuselage bottom

Check the landing gear for general condition; check the wheel

fairings if installed, the tires for wear and proper pressure

Check and, if required, adjust the brake control

Check the nose gear elastic chord and the sliding strut for excess

of play, clean and lubricate properly

Check the pedal rods and rod-ends; clean and lubricate properly

WARNING: following a hard landing, particularly if happened in

a crosswind situation, check the wheel fork alignment.

Check all the bolts, nuts and attachment connections of the wings:

all the safety locking devices should be in place and not broken

Check the flaperon hinges: they should be show freedom of

movement and no play and be fitted with the safety locks

Clean all the flaperon hinges and lubricate

Check all the empennages hinges for freedom of movement and

no play, clean and lubricate; Check the cable end attachment

fittings for condition, freedom of movement, no play, cleanliness

and lubrication

Inspect for condition and security the four (4) horizontal tailplane

to fuselage attachment connections

Check all the inspection panels for condition and security, their

hinges and fasteners; clean and lubricate properly

Inside the cabin check for general condition, open the control

stick repair, check all hinges, screws, nuts, safety locks, for

freedom of movement, excessive play

Lubricate the control stick mechanism (3 spots)

Close the control stick repair; make sure to fix it.

Visually inspect the cabin electrical system, the brake system’s

pipes and cables, the cabin switches, breakers, all controls

Lubricate the brake system cables and the rudder pedals

Clean all inside the cabin

NOTE: to properly maintain the engine it’s strongly

recommended to follow the engine manufacturer instructions

and all Rotax service informations

Fuel system: visually inspect pipes, clamps, fuel filter, electric

pump and mechanical pump; clean and inspect float chambers and