IDEC MICRO/I HG2G Series User manual

1

B-1243(5)

INSTRUCTION SHEET

Operator Interface

HG2GSeries

Confirm that the delivered product is what you have ordered. Read this instruction sheet to make

sure of correct operation. Make sure that the instruction sheet is kept by the end user.

SAFETY PRECAUTIONS

In this operation instruction sheet, safety precautions are categorized in order of importance to

Warning and Caution:

Warning notices are used to emphasize that improper operation may cause severe personal

injury or death.

Caution notices are used where inattention might cause personal injury or damage to equipment.

● When using the HG2G in applications which require high reliability and safety, such as

nuclear equipment, railways, aircraft, medical equipment, and vehicles, add a failsafe or

backup functionality and verify an adequate level of safety using the product specifications.

● Turn off the power to the HG2G before installation, removal, wiring, maintenance, and

inspection of the HG2G. Failure to turn power off may cause electrical shock or fire hazard.

● Special expertise is required to install, wire, configure, and operate the HG2G. People

without such expertise must not use the HG2G.

● The HG2G uses an LCD (liquid crystal display) as a display device. The liquid inside the

LCD is harmful to the skin. If the LCD is broken and the liquid attaches to your skin or clothes,

wash the liquid off using soap, and consult a doctor immediately.

● Emergency and interlocking circuits must be configured outside the HG2G.

● Replace battery with UL recognized battery, model CR2032 only. Use of another battery may

present a risk of fire or explosion. See instruction sheet for safety instructions.

● Install the HG2G according to the instructions in the Instruction Manual. Improper installation

will result in falling, failure, electrical shock, fire hazard, or malfunction of the HG2G.

● The HG2G is designed for use in pollution degree 2. Use the HG2G in environments of

pollution degree 2.

● The HG2G uses “PS2 of EN61131” as DC power supply.

● Prevent the HG2G from falling while moving or transporting, otherwise damage or

malfunction of the HG2G will result.

● Prevent metal fragments or wire chips from dropping inside the HG2G housing. Ingress of

such fragments and chips may cause fire hazard, damage, and malfunction.

● Use a power supply of the rated value. Using a wrong power supply may cause fire hazard.

● Use wire of a proper size to meet the voltage and current requirements.

● Use fuses or circuit protectors on the power line outside the HG2G.

● When exporting the HG2G to Europe, use an EN60127 ( EC60127) approved fuse or an

EU-approved circuit protector.

● Do not push hard or scratch the touch panel and protection sheet with a hard object such as

a tool, because they are damaged easily.

● Make sure of safety before starting and stopping the HG2G. Incorrect operation of the HG2G

may cause mechanical damage or accidents.

● When disposing of the HG2G, do so as an industrial waste.

UL/c-UL Compliance and Handling Cautions

● This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

Non-Hazardous locations only.

● Warning - Explosion Hazard - Substitution of components may impair suitability for Class I,

Division 2

● Warning - Explosion Hazard - Do not disconnect equipment unless power has been

switched off or the area is known to be Non-Hazardous.

● Replace battery with UL recognized battery, model CR2032 or CR2032H only. Use of another

battery may present a risk of fire or explosion. See instruction sheet for safety instructions.

● Caution - Battery may explode if mistreated. Do not recharge, disassemble or dispose of in

fire.

● Warning - Explosion Hazard – Batteries must only be changed in an area known to be

Non-Hazardous.

● For Indoor Use Only, Pollution Degree 2 Environment, in an area that is dry and free of

contaminates.

● Avertissement: Risque d'explosion. La substitution de composants peut rendre ce matériel

inacceptable pour les emplacements de classe I, division 2.

● Avertissement: Risque d'explosion. Avant de déconnecter l'equipement, couper le courant

ou s'assurer que l'emplacement est désigné non dangereux.

● Avertissement: Risque d'explosion. Afin d'éviter tout risque d'explosion, s'assurer que

l'emplacement est désigné non dangereux avant de changer la batterie.

● Attention: Risque d’explosion de la batterie en cas de mauvaise utilisation. Ne pas recharger,

démonter ou jeter la batterie au feu.

1Package Content

Before installing the HG2G, make sure that the specifications of the product conform to your

requirements, and that no parts are missing or damaged due to accidents during transportation.

●Main Unit (24VDC Type)

Display Device Interface Model No.

5.7-inch

STN color LCD

RS232C, RS422/485 HG2G-SS22VF-□

RS232C, RS422/485

& Ethernet HG2G-SS22TF-□

5.7-inch

STN monochrome LCD

RS232C, RS422/485 HG2G-SB22VF-□

RS232C, RS422/485

& Ethernet HG2G-SB22TF-□

□ indicates the bezel color.

●Main Unit (12VDC Type)

Display Device Interface Model No.

5.7-inch

STN color LCD

RS232C, RS422/485 HG2G-SS21VF-□

RS232C, RS422/485

& Ethernet HG2G-SS21TF-□

5.7-inch

STN monochrome LCD

RS232C, RS422/485 HG2G-SB21VF-□

RS232C, RS422/485

& Ethernet HG2G-SB21TF-□

□ indicates the bezel color.

●Accessories

Mounting Clip (4)

Host communication plug (1)

(Attached to the Main Unit)

Instruction Sheet (Japanese/English)

[This manual] 1 each

2Type No. Development

HG2G-S#2$*F-%

# Display S: STN color LCD

B: STN monochrome LCD

$ Power supply 2: 24VDC

1:12VDC

* Interface V: RS232C, RS422/485

T: RS232C, RS422/485 & Ethernet

% Bezel color W: Light gray

B:Darkgray

S:Silver

3Specifications

Safety Standards

UL508, ANSI/ISA 12.12.01

CSA C22.2 No.142 CSA C22.2 No.213

IEC/EN61131-2

EMC Standards IEC/EN61131-2

Electrical Specifications

Rated Operating Voltage HG2G-S#22*F-% : 24V DC

HG2G-S#21*F-% : 12V DC

Power Voltage Range

HG2G-S#22*F-%

85% to 120% of the rated voltage (24VDC)

HG2G-S#21*F-%

85% to 150% of the rated voltage (12VDC)

(including ripple)

Power Consumption 10W maximum

Allowable Momentary

Power Interruption

10 ms maximum, Level: PS-2

( EC/EN61131)

Inrush Current HG2G-S#22*F-% : 20A maximum

HG2G-S#21*F-% : 40A maximum

Dielectric Strength 1000V AC, 10 mA, 1 minute

(between power terminals and FG)

Insulation Resistance 50 MΩminimum (500V DC megger)

(between power terminals and FG)

Backup Battery

Built-in CR2032 lithium primary battery

Standard replacement cycle: 5 years

Guaranteed term: 1 year (at 25°C)

Environmental Specifications

Operating Ambient Temperature 0 to 50°C

Operating Relative Humidity 10 to 90% RH (no condensation)

Storage Ambient Temperature -20 to 60°C

Storage Relative Humidity 10 to90% RH (no condensation)

Altitude 0 to 2000m (operation)

0 to 3000m (transportation) (IEC61131-2)

Vibration Resistance

(Damage Limits)

5 to 9 Hz, amplitude 3.5 mm

9 to 150 Hz, 9.8 m/s2

X, Y, Z directions for 10 cycles [100 minutes]

(IEC60068-2-6)

Shock Resistance

(Damage Limits)

147 m/s2, 11 ms

5 shocks each in 3 axes (IEC60068-2-27)

Pollution Degree 2 (IEC60664-1)

Corrosion Immunity Free from corrosive gases

Construction

S

p

ecifications

Degree of Protection

P65 *1

TYPE 13 *2

(In the front of panel attachment.)

Terminal Power supply terminal: M3

Tightening torque 0.5 to 0.6 N・m

Dimensions 167.2 (W) × 134.7 (H) × 40.9 (D) mm

Weight (Approx.) 500g

2

Noise Specifications

Electrostatic Discharge

ESD-3 (RH-1) : Level 3

Contact ±6 kV / Air ± 8 kV

(IEC/EN61000-4-2)

Electromagnetic Field

AM80%

10 V/m 80 MHz to 1000 MHz

3 V/m 1.4 GHz to 2.0 GHz

1 V/m 2.0 GHz to 2.7 GHz

(IEC/EN61000-4-3)

Fast Transient

Burst Withstandability

Common mode: Level 3

Power supply: ±2 kV

Communication line: ±1 kV

(IEC/EN61000-4-4)

Surge Immunity

HG2G-S#22*F-%:

500V between +24V-0V,

1kV between +24V-FG, 0V-FG

HG2G-S#21*F-%:

500V between +12V-0V,

1kV between +12V-FG, 0V-FG

(IEC/EN61000-4-5)

Conducted Radio

Frequency Immunity

0.15 to 80MHz 80%AM (1kHz) 3V

(IEC/EN61000-4-6)

Radiated Emission IEC/EN61000-6-4

*1 Protection degree of the front surface after mounting. Operation not guaranteed under

certain environments.

*2 Protection against certain types of oil materials are not guaranteed under Type 13.

4Installation

● Operating Environment

For designed performance and safety of the HG2G, do not install the HG2G in the following

environments:

・ Where dust, briny air, or iron particles exist.

・ Where oil or chemical splashes for a long time.

・ Where oil mist is filled.

・ Where direct sunlight falls on the HG2G.

・ Where strong ultraviolet rays fall on the HG2G.

・ Where corrosive or combustible gasses exist.

・ Where the HG2G is subjected to shocks or vibrations.

・ Where condensation occurs due to rapid temperature change.

・ Where high-voltage or arc-generating equipment (electromagnetic contactors or circuit

protectors) exists in the vicinity.

● Ambient Temperature

・ The HG2G is designed to install on a vertical plane so that natural air-cooling is provided.

Keep as much space as possible around the HG2G. Allow 100mm minimum clearance

above and below the HG2G.

・ Do not install the HG2G where the ambient temperature exceeds the rated operating

ambient temperature range. When mounting the HG2G in such locations, provide a forced

air-cooling fan or air-conditioner to keep the ambient temperature within the rated

temperature range.

● Panel Cut-out Dimensions

Place the HG2G in a panel cut-out and fasten with the attached mounting clips at four places to

a specified torque of 0.12 to 0.17 N・m uniformly.

Do not tighten excessively, otherwise the HG2G may warp and cause wrinkle on the display, or impair

the waterproof characteristics.

・ If the mounting clips are tightened obliquely to the panel, the HG2G may fall off the panel.

・ When installing the HG2G into a panel cut-out, make sure that the gasket is not twisted.

Especially when re-installing, take special care because any twists in the gasket will impair

the waterproof characteristics.

5Notes for Operation

・ The screen becomes blank when the backlight is burnt out; however, the touch panel

remains enabled. Incorrect touch panel operation will occur when operating the touch panel

when the backlight appears to be turned off but is actually burnt out. Note that this erroneous

operation may result in damage.

・ At temperatures over the rated operating temperature, the clock accuracy is affected. Adjust

the clock before use.

・ For applications which require clock accuracy, adjust the clock periodically.

・ When more than one button is pressed at the same time, due to the detection characteristics

of an analog type touch panel, only the gravity center of the pressed area is sensed and the

unit assumes that only one button is pressed. Thus, when more than one button is pressed

simultaneously, the resulting operation is not guaranteed.

・ Do not install the HG2G in areas subjected to strong ultraviolet rays, since ultraviolet rays

may impair the quality of the LCD.

・ Use WindO/I-NV2 version 4.10 or later for the 12V DC power type HG2G operator interfaces.

If an older version of configuration software is used to download the system program, an

incorrect product Type No.is displayed on the system information screen.

6Wiring

・ Turn off the power supply before wiring.

・ Make the wiring as short as possible and run all wires as far away as possible from

high-voltage and large-current cables. Follow all the procedures and precautions when

wiring the HG2G.

● Power Supply Terminals

Pin assignment is shown in the following table.

+

Power supply

HG2G-S#22*F-% : 24V DC

HG2G-S#21*F-% : 12V DC

- Power supply 0V

Functional Earth

・ Use applicable cables for wiring and recommended ferrules (made by Phoenix Contact) as

follows:

Applicable cable AWG18 to AWG22

Recommended

Pressure Terminal

AI 0,34-8 TQ

AI 0,5-8 WH

AI 0,75-8 GY

AI 1-8 RD

AI-TWIN 2 x 0,5-8 WH

AI-TWIN 2 x 0,75-8 GY

AI-TWIN 2 x 1-8 RD

Tightening Torque 0.5 to 0.6 N・m

・ For power supply wiring, twist the wires as close as possible and make the power supply

wiring as short as possible.

・ Separate the HG2G power supply wiring from the power lines of I/O devices and motor

equipment.

・ Ground the functional ground terminal to make sure of correct operation.

・ HG2G operator interfaces operate on 12 or 24V DC depending on the model. Make sure

that the correct voltage is supplied to the HG operator interface.

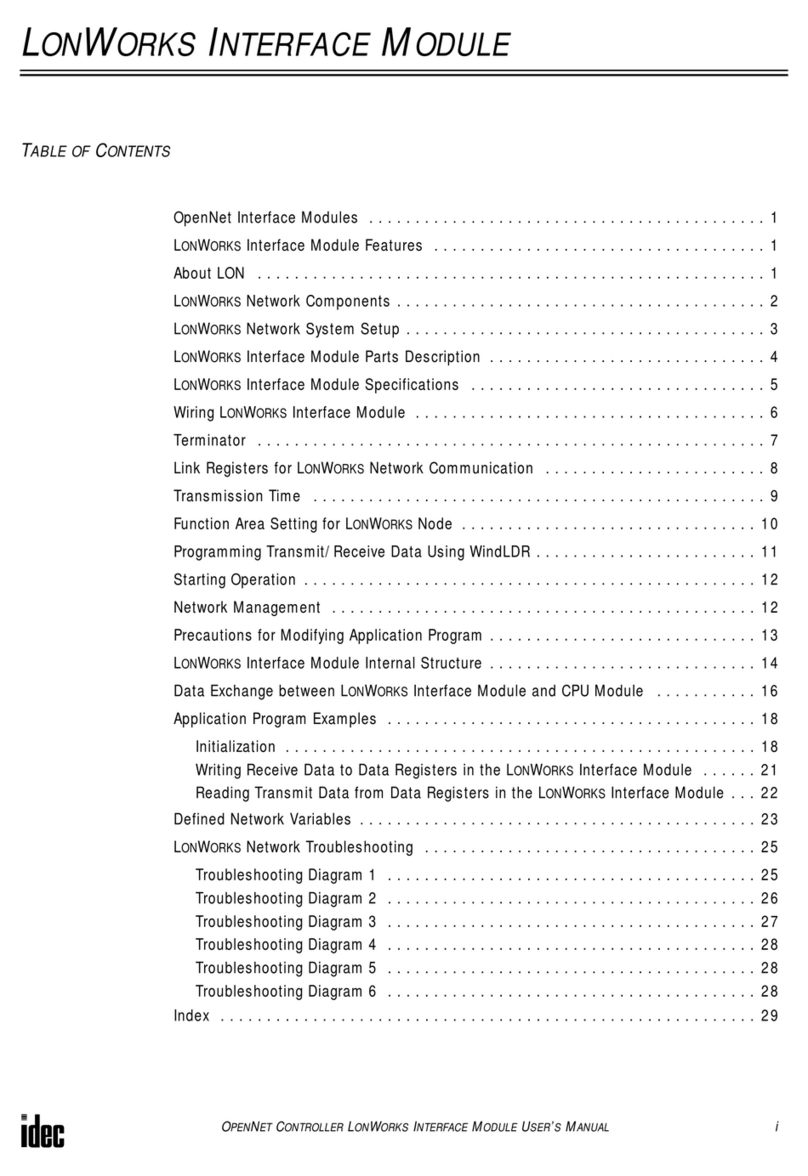

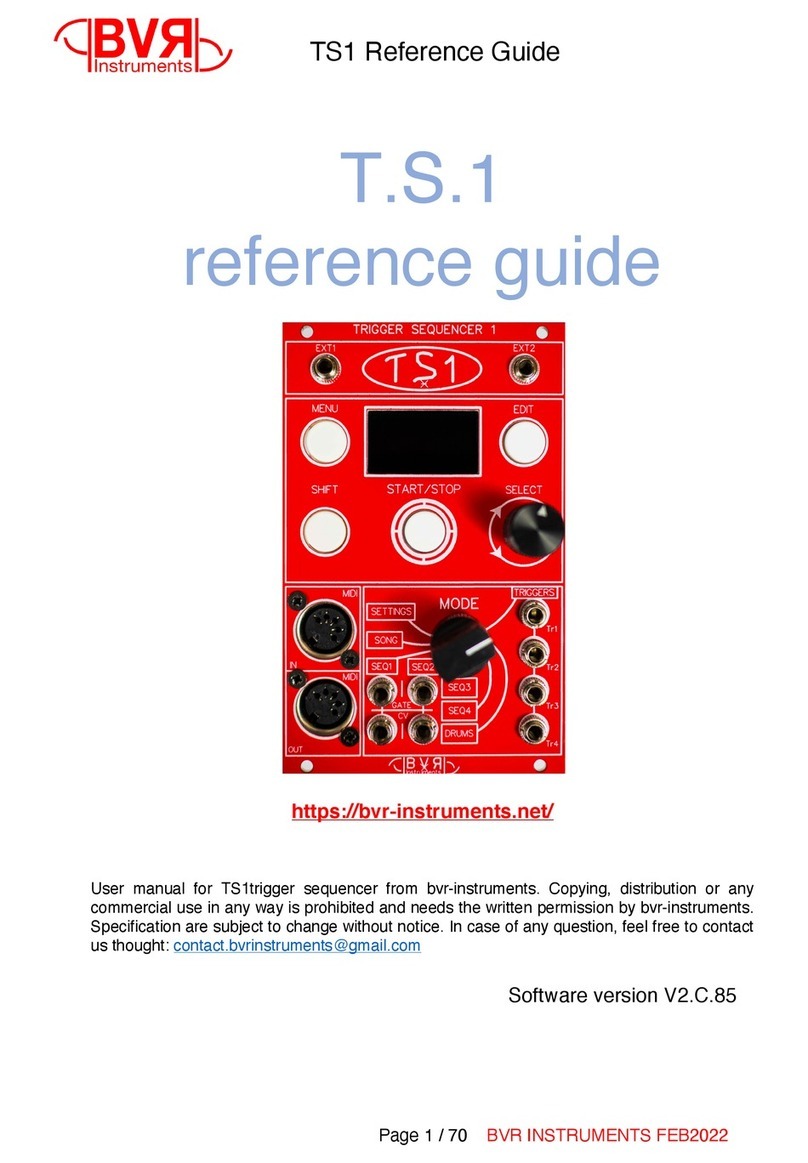

7Dimensions

All Dimensions in mm

①Display (5.7 inch STN LCD)

②Touch Panel (Analog resistance membrane method)

③Status LED

④Serial Interface 1

⑤Serial Interface 2

⑥O/I Link Interface

⑦Ethernet Interface

⑧Terminating Resistor Selector SW (for RS422/485 interface)

⑨Battery Holder Cover

⑩Mounting Clip Position

⑪Gasket

Panel Mounting

Clip

HG2G

B

A: 121+2

B: 153+2

Panel Thickness: 1.6 to 5

Dimensions in mm

-0

-0

A

3

・ Make sure to turn off the power to the HG2G before attaching the O/I link unit or replacing

the internal battery. Do not touch the printed circuit board in the HG2G and other devices.

Otherwise, failure of the HG2G and other devices may be caused.

・ Hold the connector when disconnecting the maintenance cable from serial interface 2. Do

not pull the maintenance cable.

8Interface

・ Make sure to turn off the power to the HG2G before wiring each interface or switching the

terminating resistor selector SW.

●Serial interface 1

Serial interface 1 is used for host communication (RS232C or RS422/485).

・Use applicable cables for wiring.

Applicable cable AWG20 to AWG22

Recommended

Pressure Terminal

AI 0,34-8 TQ

AI 0,5-8 WH

AI-TW N 2 x 0,5-8 WH

(Phoenix Contact)

Tightening Torque 0 22 to 0.25 N・m

No. Name I/O Function Communication

type

1 SD OUT Send Data

RS232C

2 RD N Receive Data

3 RS OUT Request to Send

4 CS N Clear to Send

5 SG - Signal Ground

RS422

/485

6 SDA OUT Send Data (+)

7 SDB OUT Send Data (-)

8 RDA N Receive Data (+)

9 RDB N Receive Data (-)

・Note that only one of the RS232C or RS422/485 interfaces can be used at one time.

・Wiring both interfaces will result in failure of the HG2G. Wire only the interface used.

・Terminating Resistor Selector Switch (for RS422/485 interface)

When using RS422/485 interface, set the Terminating Resistor Selector SW to the ON side.

This will connect the internal terminating resistor (100Ω) between RDA and RDB.

●Serial interface 2

Serial interface 2 is used for maintenance communication (RS232C).

No. Name I/O Function

1 RS OUT Request to Send

2 ER OUT Data Terminal Ready

3 SD OUT Send Data

4 RD N Receive Data

5 DR N Data Set Ready

6 EN N Cable Recognition

7 SG - Signal Ground

8 NC - No Connection

Do not connect pin 6 (EN) with any other pins except when performing maintenance

communications for downloading project data.

●O/I Link interface (Option)

Method Dedicated Interface to O/I Link Unit

Connector Dedicated connector

The HG2G Operator Interface can be connected to an O/I Link Unit for 1:N communication with

a PLC. This allows high-speed communication with the PLC host.

●Ethernet interface

EEE802.3 standard compliant (10/100Base-T)

No. Name /O Function

1 TPO+ OUT Send Data (+)

2 TPO- OUT Send Data (-)

3 TPI+ IN Receive Data (+)

4 NC - No Connection

5 NC - No Connection

6 TPI- IN Receive Data (-)

7 NC - No Connection

8 NC - No Connection

9Replacing the Backlight

The HG2G’s backlight cannot be replaced by the customer. When the backlight needs to be

replaced, Contact IDEC.

10 Replacing the Backup Battery

A backup battery is built into the HG2G to retain the internal backup data (log data, keep resister,

and keep relay) and clock data.

When the “Replace the battery” message is displayed, replace the backup battery by following the

procedure below.

When the “Battery level LOW” message is displayed, replace the battery immediately; otherwise,

the backup data and clock data may be lost.

Whether or not to display the reminder message for battery replacement can be specified with the

configuration software. Refer to the Instruction Manual for details.

(1) Turn off the power to the HG2G and disconnect the cable.

(2) Remove the battery holder cover.

(3) Turn on the power to the HG2G, wait for approximately one minute, and then turn off the

power again.

・ After turning off the power to the HG2G in step (3), complete the steps through (5) within 30

seconds to replace the battery without losing the backup data and clock data. However, it is

recommended that the backup data be transferred to flash memory as a precautionary measure.

For the procedure to transfer the data to flash memory, refer to the Instruction Manual. If it is not

necessary to save the data, step (3) can be skipped.

(4) Insert a flathead screwdriver into the battery holder as shown in the figure, and remove the

battery. The battery may pop out from the battery holder.

(5) Put a new replacement battery into the battery holder.

(6) Replace the battery holder cover into the original position. Replace the battery holder cover

on the HG2G, and turn it clockwise to lock the cover.

6

3

4

7

8

5

21

ON

OFF

4

・ The operating life of the internal battery is approximately five years. It is recommended to

replace the battery every five years even before the reminder message for battery replacement

is displayed.

IDEC provides replacement service for the battery (at customer’s expense). Contact IDEC.

The battery may be regulated by national or local regulation. Observe the instructions of proper

regulation. As electric capacity is left in a discarded battery and it comes into contact with other

metals, it could lead to distortion, leakage, overheating, or explosion, so make sure to cover the

(+) and (-) terminals with insulating tape before disposal.

When replacing the battery, use the specified battery only. Note that any problems and failures

arising from or in connection with the use of a battery other than the specified battery is not

guaranteed.

Handling of Batteries and Devices with Built-in Batteries in EU Member States

Note) The following symbol mark is for EU countries only.

This symbol mark means that batteries and accumulators, at their end-of life, should be

disposed of separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means

that the battery or accumulator contains a heavy metal at a certain concentration. This will be

indicated as follows :

Hg : mercury (0.0005%), Cd : cadmium (0.002%), Pd : lead (0.004%)

In the European Union there are separate collection systems for used batteries and

accumulators.

Please dispose of batteries and accumulators correctly in accordance with each country or

local regulation.

11 Adjusting the Contrast

The contrast of the HG2G display can be adjusted on the Adjust Contrast Screen. Adjust the

contrast to the best condition as required. To ensure the best contrast, adjust the contrast

approximately 10 minutes after turning on the power.

Permission to show the Maintenance Screen can be set using the configuration software. Refer to

the Instruction Manual for details.

(1) Turn on the power to the HG2G, then press and hold the touch panel on the upper-left

corner of the screen for three seconds or longer. The Maintenance Screen appears on the

screen.

(2) Press the Adjust Contrast at the bottom of the Maintenance Screen. The Adjust

Contrast Screen appears.

(3) Press the ←or →at the bottom the Adjust Contrast Screen to adjust the contrast to the

optimal setting.

(4) Press the X to close the Adjust Contrast Screen.

The Maintenance Screen is not displayed in System Mode. To adjust the contrast in System Mode,

use the << and >> buttons located at the bottom of the top page.

12 Adjusting the Touch Panel

A gap may be caused in the operation accuracy of the touch panel by the secular distortion, etc.

Readjust the touch panel according to the following procedure when there is a gap in the operation

of the touch panel.

●Touch panel adjustment procedure

(1) Press the System Mode at the top of the Maintenance Screen. The Top page Screen

appears.

Press the Offline , then the Main Menu Screen appears.

(2) Press in order of Initial Setting →Initialize →Touch Panel Adjust . The confirmation

screen appears and asks “Adjust Touch Panel setting?”

Press the Yes. , then the Touch Panel Adjust screen appears.

(3) Press the center of the Xmark, then the position of the mark changes one after another.

Press five marks sequentially.

(4) When normally recognized, the confirmation screen of (2) is restored.

At procedure (3), when pressing a point away from the center of the Xmark, a recognition

error will result. Then the Xmark returns to the initial position, then repeat the procedure of

(3) again.

13 Maintenance and Inspection

Maintain and inspect the HG2G periodically to ensure the best performance. Do not

disassemble, repair, or modify the HG2G during inspection.

・ Wipe any stain off the display using a soft cloth slightly dampened with neutral detergent or

alcoholic solvent. Do not use solvents such as thinner, ammonia, strong acid, and strong

alkaline.

・ Check the terminals and connectors to make sure of no loose screws, incomplete insertion,

or disconnected lines.

・ Make sure that all mounting clips and screws are tightened sufficiently. If the mounting clips

are loose, tighten the screw to the recommended tightening torque.

http://www.idec.com

2016 6

Manufacturer: DEC CORP.

2-6-64 Nishimiyahara Yodogawa-ku, Osaka 532-0004, Japan

EU Authorized Representative: IDEC Elektrotechnik GmbH

Heselstuecken 8, 22453 Hamburg, Germany

System Mode

Maintenance ×

Device Monitor

Adjust Contrast

A

djust Contras

t

Maintenance ×

← →

This manual suits for next models

8

Other IDEC Recording Equipment manuals