Jetter JetViewMobile 104 User manual

User Manual

JVM-104-O08

HMI

60884475_01

We automate your success.

This document has been compiled by Jetter AG with due diligence based on the state of the art as

known to them. Any revisions and technical advancements of our products are not automatically made

available in a revised document. Jetter AG shall not be liable for any errors either in form or content, or

for any missing updates, as well as for any damage or detriment resulting from such failure.

Jetter AG

Graeterstrasse 2

71642 Ludwigsburg

Germany

Phone

Switchboard +49 7141 2550-0

Sales +49 7141 2550-663

Technical hotline +49 7141 2550-444

E-mail

Technical hotline [email protected]

Sales [email protected]

www.jetter.de

Translation of the german original User Manual

Revision 4.12.1

Date of issue 4/3/2023

Jetter AG Table of contents

User Manual – JVM-104-O08 iii

Table of contents

1 Introduction ....................................................................................................................................... 5

1.1 Information on this document .................................................................................................. 5

1.2 Typographical conventions...................................................................................................... 5

2 Safety................................................................................................................................................ 6

2.1 General Information................................................................................................................. 6

2.2 Purpose ................................................................................................................................... 6

2.2.1 Intended use................................................................................................................ 6

2.2.2 Usage other than intended .......................................................................................... 6

2.3 Warnings used in this document.............................................................................................. 7

3 Product description ........................................................................................................................... 8

3.1 Design...................................................................................................................................... 8

3.2 Product features ...................................................................................................................... 8

3.3 Nameplate ............................................................................................................................... 9

3.4 Scope of delivery ..................................................................................................................... 9

4 Technical data................................................................................................................................... 10

4.1 Dimensions .............................................................................................................................. 10

4.2 Mechanical specifications........................................................................................................ 10

4.3 Electrical properties ................................................................................................................. 11

4.3.1 Ports and interfaces..................................................................................................... 11

4.4 Environmental conditions......................................................................................................... 12

4.5 Display ..................................................................................................................................... 12

4.6 Acoustic signal generator ........................................................................................................ 12

4.7 EMI values............................................................................................................................... 13

5 Mechanical installation...................................................................................................................... 14

5.1 Requirements for the installation location................................................................................ 15

5.2 Preparing for installation.......................................................................................................... 16

5.3 Installing the HMI..................................................................................................................... 17

6 Electrical connection ......................................................................................................................... 19

6.1 Pin assignment ........................................................................................................................ 20

6.1.1 M12 male connector – voltage supply, CAN, ignition .................................................. 20

Jetter AG Table of contents

User Manual – JVM-104-O08 iv

7 Identification and Configuration ........................................................................................................ 21

7.1 Operating system..................................................................................................................... 21

7.1.1 Operating system update of the HMI........................................................................... 21

7.2 File system............................................................................................................................... 24

7.2.1 Features ...................................................................................................................... 24

8 Programming .................................................................................................................................... 26

8.1 Abbreviations, module register properties and formats ........................................................... 26

8.2 CANopen STX API .................................................................................................................. 27

8.2.1 STX Functions ............................................................................................................. 27

8.2.2 CANopen object directory............................................................................................ 28

8.3 Storage options - Overview ..................................................................................................... 29

8.3.1 Operating system memory .......................................................................................... 29

8.3.2 File system memory .................................................................................................... 29

8.3.3 Application program memory....................................................................................... 30

8.3.4 Special registers .......................................................................................................... 30

8.3.5 Flag.............................................................................................................................. 30

8.3.6 Storing registers and variables .................................................................................... 31

8.4 Control elements...................................................................................................................... 32

8.4.1 Input keys .................................................................................................................... 32

8.4.2 Digipot ......................................................................................................................... 33

8.5 Ignition and OFF delay ............................................................................................................ 34

8.6 Saving and loading an application program ............................................................................ 36

9 Registers - Overview......................................................................................................................... 37

10 Maintenance ..................................................................................................................................... 45

10.1 Repairs .................................................................................................................................... 45

10.2 Return and disposal................................................................................................................. 45

10.3 Storage and shipment.............................................................................................................. 46

11 Service .............................................................................................................................................. 47

11.1 Customer service..................................................................................................................... 47

12 Spare parts and accessories ............................................................................................................ 48

12.1 Accessories ............................................................................................................................. 48

Jetter AG Introduction | 1

User Manual – JVM-104-O08 5

1 Introduction

1.1 Information on this document

This document forms an integral part of the product and must be read and under-

stood prior to using it. It contains important and safety-related information for the

proper use of the product as intended.

Target groups This document is intended for specialists with appropriate qualifications.

Only competent and trained personnel is allowed to put this device into operation.

During the whole product life cycle, safe handling and operation of the device

must be ensured. In the case of missing or inadequate technical knowledge or

knowledge of this document any liability is excluded.

Availability of

information Make sure this document is kept at the ready in the vicinity of the product

throughout its service life.

For information on new revisions of this document, visit the download area on our

website. This document is not subject to any updating service.

Start | Jetter - We automate your success.

For further information refer to the following information products:

■JetSym software Online Help

Detailed description of software functions with application examples

■Application-oriented manuals

Cross-product documentation

■Version updates

Information about new versions of software products or of the operating sys-

tem of your device

1.2 Typographical conventions

This manual uses different typographical effects to support you in finding and

classifying information. Below, there is an example of a step-by-step instruction:

üThis symbol indicates requirements which have to be met before executing

the following action.

►This sign or a numbering at the beginning of a paragraph marks an action in-

struction that must be executed by the user. Execute the instructions one af-

ter the other.

ðThe target after a list of instructions indicates reactions to, or results of these

actions.

INFO Further information and practical tips

In the info box you will find helpful information and practical

tips about your product.

Jetter AG Safety | 2

User Manual – JVM-104-O08 6

2 Safety

2.1 General Information

When placed on the market, this product corresponds to the current state of sci-

ence and technology.

In addition to the operating instructions, the laws, regulations and guidelines of

the country of operation or the EU apply to the operation of the product. The op-

erator is responsible for compliance with the relevant accident prevention regula-

tions and generally accepted safety rules.

RoHS 2 The device conforms to the EU directive 2011/65/EU (RoHS 2).

2.2 Purpose

2.2.1 Intended use

The JVM-104-O08 is intended for installation in commercial vehicles and self-pro-

pelled machines. It is an HMI with integrated controller for exchange of data with

peripheral devices.

Operate the device only in accordance with the intended conditions of use, and

within the limits set forth in the technical specifications.

Intended use of the product includes its operation in accordance with this man-

ual.

SELV/PELV If this device is not used in a vehicle or mobile machine, a SELV or PELV power

supply unit must be used to supply the device.

2.2.2 Usage other than intended

This device must not be used in technical systems which to a high degree have

to be fail-safe.

Machinery Directive This device is no safety-related part as per Machinery Directive 2006/42/EC, and

must, therefore, not be used for safety-relevant applications. This device is NOT

intended for the purpose of personal safety, and must, therefore, not be used to

protect persons.

Jetter AG Safety | 2

User Manual – JVM-104-O08 7

2.3 Warnings used in this document

DANGER

High risk

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Medium risk

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Low risk

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

Material damage

Indicates a situation which, if not avoided, could result in mal-

functions or material damage.

Jetter AG Product description | 3

User Manual – JVM-104-O08 8

3 Product description

The JVM-104-O08 is a graphical HMI. Thanks to its compact design and in-

tegrated controller, the HMI is versatile and has been specially developed

for harsh applications in commercial vehicles and self-propelled machines.

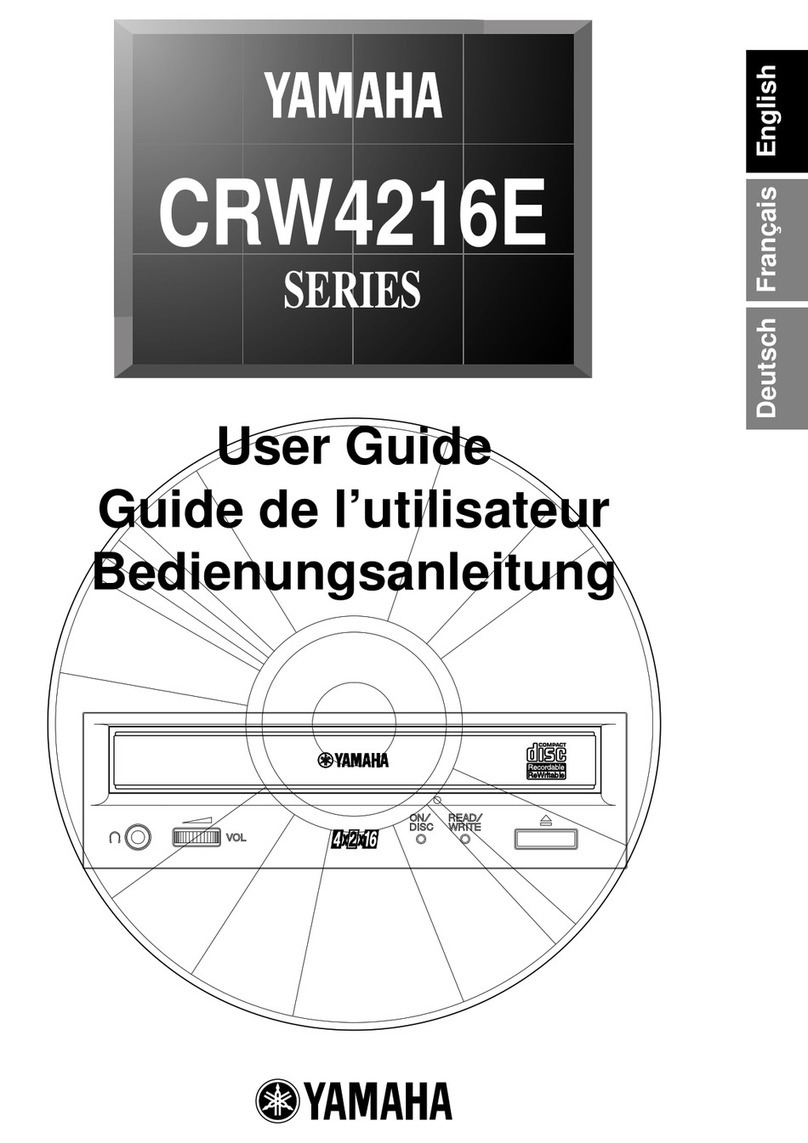

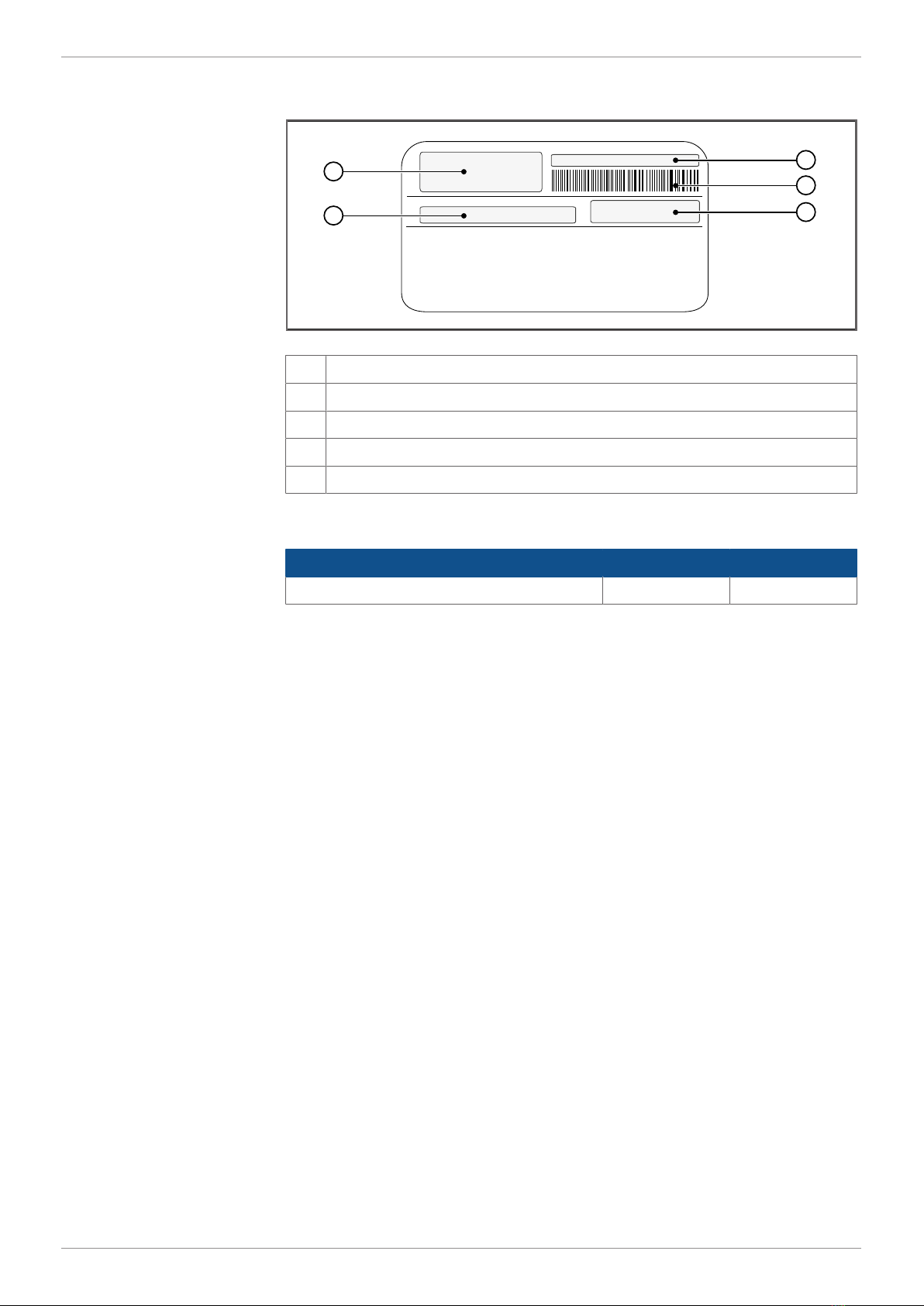

3.1 Design

1

13

12

93

48

10 2

67 5

11

11 11

11

Fig.1: Design

1 TFT display

2 F3 key

3 F4 key

4 Home key

5 ESC key

6 Digipot

7 Scroll key

8 Power key

9 F1 key

10 F2 key

11 Screw hole

12 M12 male connector

13 Nameplate

3.2 Product features

■Display: 3.5” TFT, 320x240px

■CPU: ARM11, 500MHz, 128MB RAM, 512MB Flash

■Surface mount model with connector M12x1

■Input: 8 keys, 1 DigiPot

■Ports and interfaces: 1x CAN

■Front/rear degree of protection: IP65/IP65

Jetter AG Product description | 3

User Manual – JVM-104-O08 9

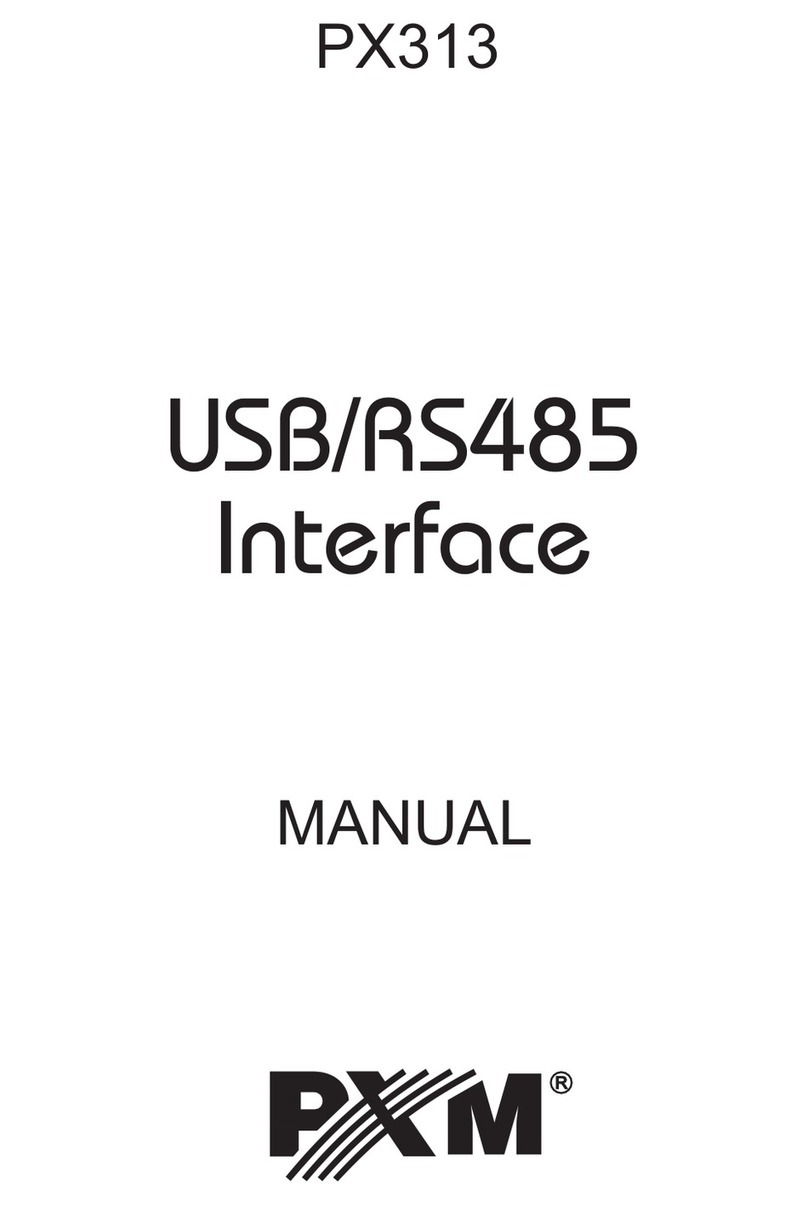

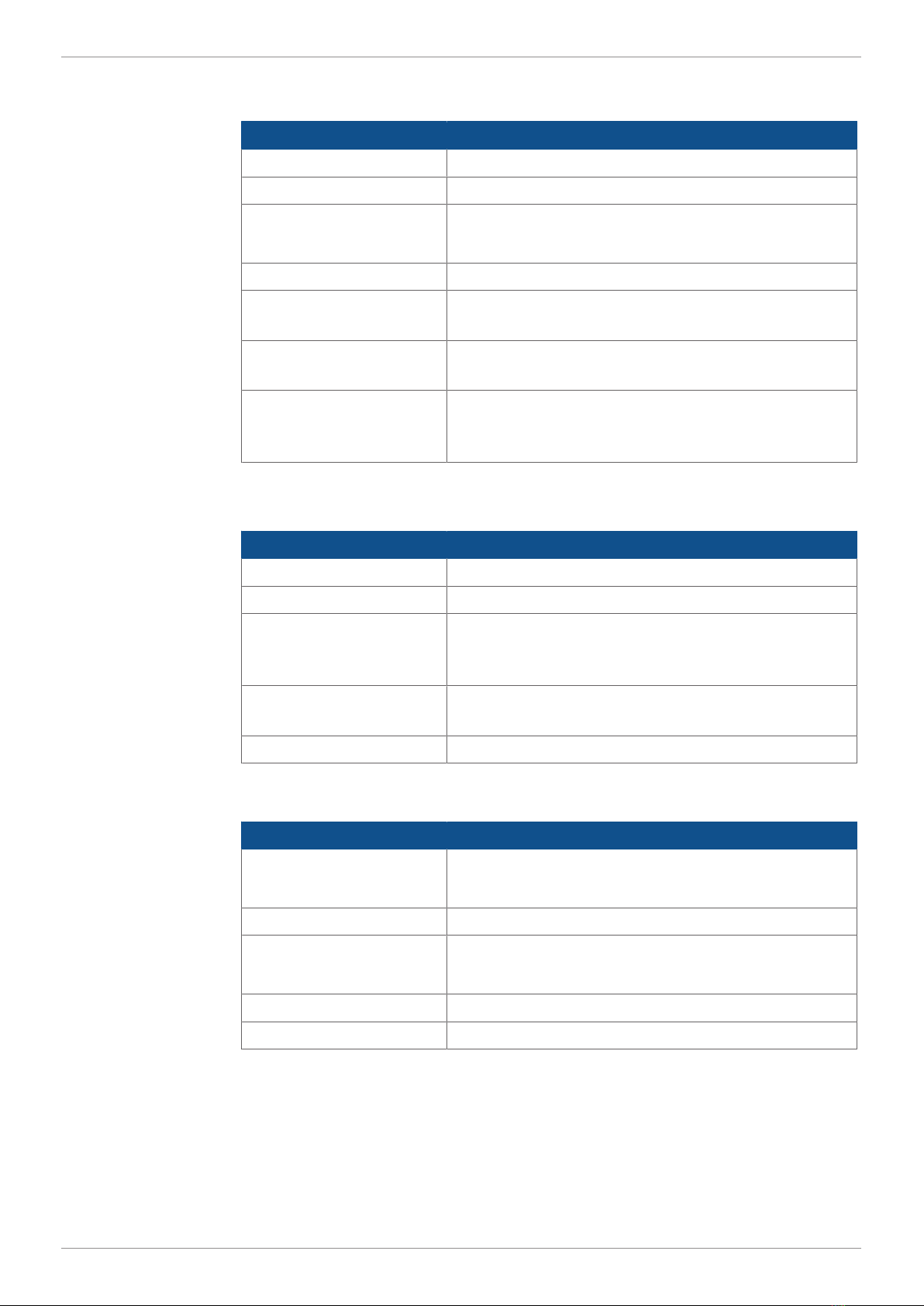

3.3 Nameplate

2

3

4

1

5

Fig.2: Nameplate

1 Logo

2 Serial number

3 Barcode

4 Article number and hardware revision

5 Model code number

3.4 Scope of delivery

Scope of delivery Item number Quantity

JVM-104-O08 10001558 1

Jetter AG Technical data | 4

User Manual – JVM-104-O08 10

4 Technical data

This chapter contains electrical, mechanical data and operating data of the

JVM-104-O08.

4.1 Dimensions

119.8

27.955

83

O3.1

4 x

55.3

5.6 28.4

66.5

104.9

Fig.3: Dimensions in mm

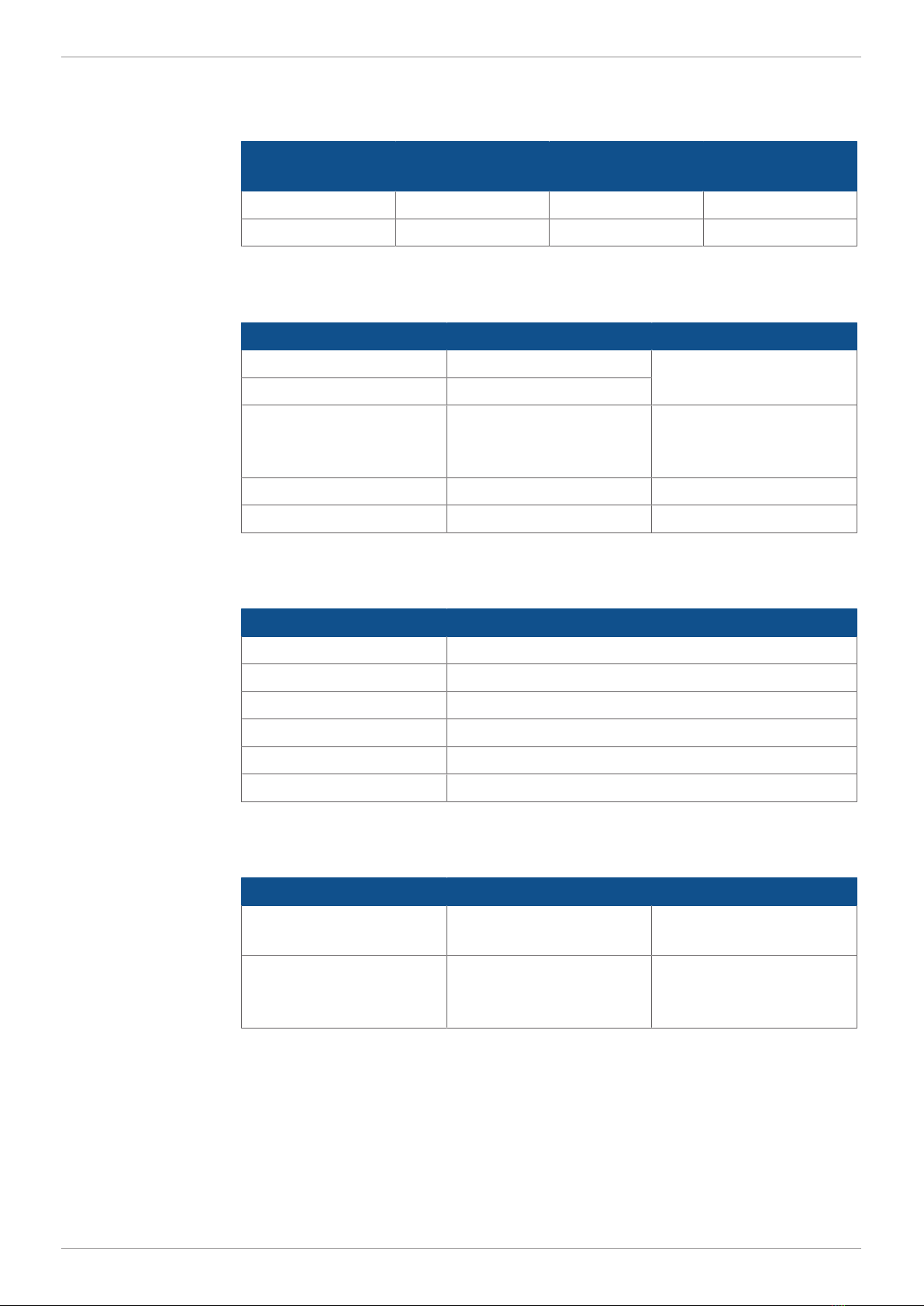

4.2 Mechanical specifications

Parameter Description Standards

Weight 350g

Vibration

Broadband noise 10Hz / 0.005(m/s2)2/Hz DINEN60068-2-64

200Hz / 0.02(m/s2)2/Hz

300Hz / 0.01(m/s2)2/Hz

350Hz / 0.002(m/s2)2/

Hz

Duration 3x 24h

Shock resistance

Type of shock Half-sine wave DINEN60068-2-27

Intensity and duration 30g (300m/s2) for

18ms

Number and direction 18shocks in all 6direc-

tions

Degree of protection

Front panel IP65 DINEN60529

Rear panel IP65

Tab.1: Mechanical specifications

Jetter AG Technical data | 4

User Manual – JVM-104-O08 11

4.3 Electrical properties

Power supply

VBAT_ECU Parameter Description

Nominal voltage DC12V or 24V

Maximum current 2A

Typical logic current con-

sumption (VBAT_ECU)

170mA at DC12V

90mA at DC24V

Power consumption Approx 2W

Integrated protective

functions

Reverse polarity protection, overvoltage, short volt-

age pulses

Permissible voltage

range VBAT_ECU

DC8V...32V

Permissible voltage

range at terminal 31 (ig-

nition)

DC8V...32V

Tab.2: Power supply VBAT_ECU

4.3.1 Ports and interfaces

CAN interface Parameter Description

Baud rate 125kBaud, 250kBaud, 500kBaud

Protocol CANopen

Default node ID on the

CANopen bus

127(0x7F)

Terminating resistance Does not exist.

Must be connected externally.

Cable specification Twisted pair conductors, unshielded

Tab.3: CAN interface specification

CAN bus cable Parameter Description

Wire cross-section 500kBaud: 0.34mm²…0.50mm2

250kBaud: 0.34mm²…0.60mm2

Cable capacitance 60pF/m max.

Resistivity 500kBaud: Max. 60Ω/km

250kBaud: Max. 60Ω/km

Number of cores 2

Twisting CAN_L and CAN_H cables are twisted pairwise

Tab.4: Specification - CAN bus cable

Jetter AG Technical data | 4

User Manual – JVM-104-O08 12

The maximum permitted cable length depends on the baud rate being used and

the number of CANopen devices being connected.

Baud rate Max. cable length Max. stub length Total cable length

500kBaud 100m 5m 30m

250kBaud 250m 10m 60m

Tab.5: Cable lengths

4.4 Environmental conditions

Parameter Description Standards

Operating temperature -20°C...+65°C ISO16750-4

Climatic conditions Humid heat

Storage temperature -20°C...+70°C ISO16750-4

DINEN60068-2-1

DINEN60068-2-2

Relative humidity 10% … 95% DINEN61131-2

Pollution degree 2 DINEN61131-2

Tab.6: Environmental conditions

4.5 Display

Parameter Description

Type TFT LCD flat screen monitor

Resolution 320 x 240Pixel

Size 3.5"

Backlighting LED, typ. 350cd/m2 , dimmable

Horizontal viewing angle 70° to each side

Vertical viewing angle 50° from above, 70° from below

Tab.7: Technical data – display

4.6 Acoustic signal generator

Parameter Description

Type Loudspeaker Adjustable frequency

and volume.

Volume 83dB 10cm distance and res-

onance frequency

2,670Hz

Tab.8: Acoustic signal generator

Jetter AG Technical data | 4

User Manual – JVM-104-O08 13

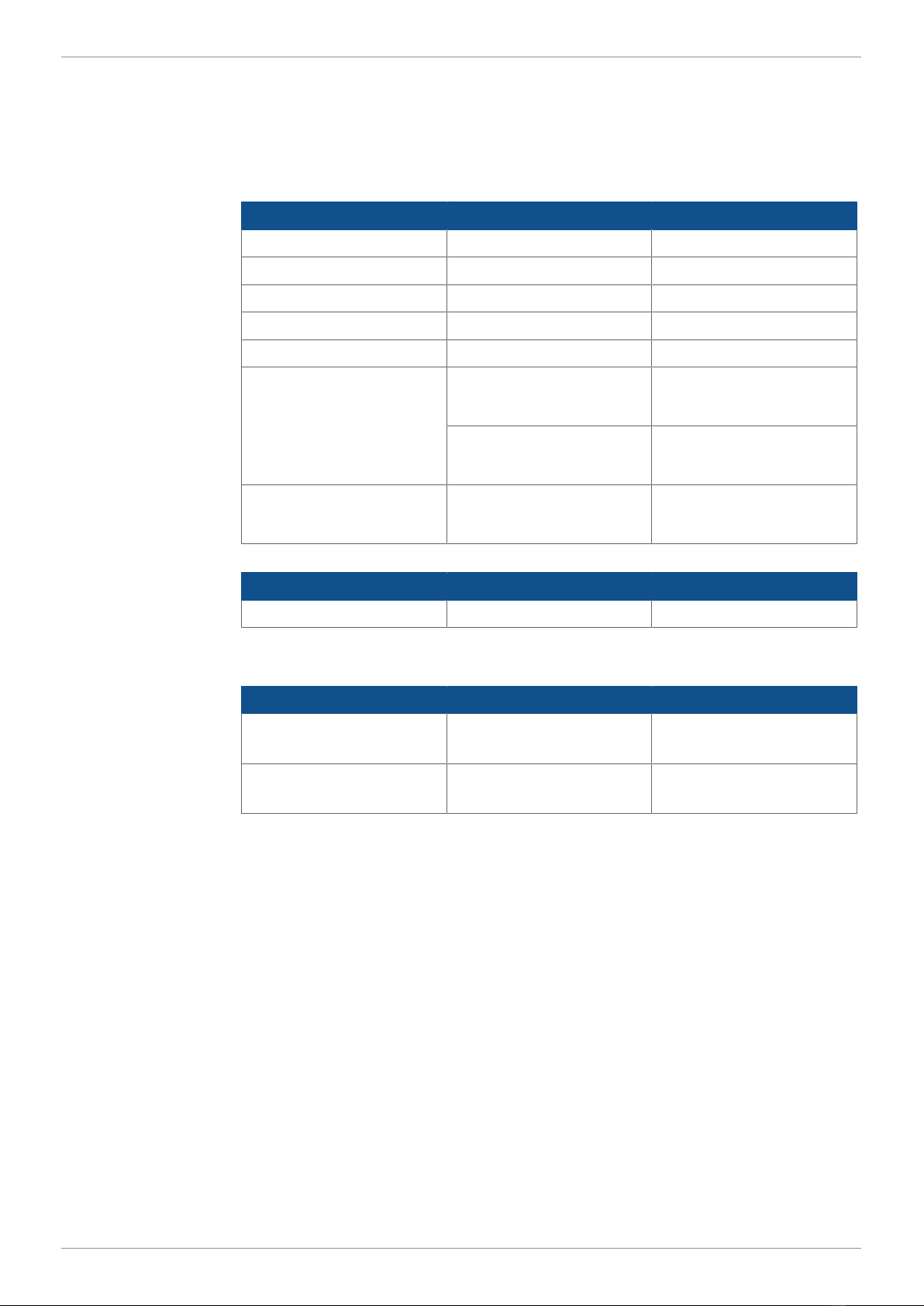

4.7 EMI values

The JVM-104-O08 has E1 approval according to ECE R10 Rev. 5 and CE con-

formity according to ISO 14982.

Pulses ISO7637-2 Test pulse Values Function class

1 -450V C

2a +37V A

2b +20V C

3a -150V A

3b +150V A

4 Ua1: -12V / 50ms

Ua2: -5V / 500ms

A (24V systems)

Ua1: -6V / 15ms

Ua2: -2.5V / 1,000ms

C (12V systems)

5b Load dump, capped

70V / 2Ω

A

Tab.9: Pulses ISO7637-2

Irradiation ISO11452 Parameter Values Function class

Irradiation 20MHz ... 2GHz 30V/m A

Tab.10: Irradiation ISO11452

ESDEN61000-4-2 Parameter Values Function class

Contact discharge ±4 kV (to conductive

surfaces)

A

Discharge through air ±8 kV (to insulating

surfaces)

A

Tab.11: ESDEN61000-4-2

Jetter AG Mechanical installation | 5

User Manual – JVM-104-O08 14

5 Mechanical installation

NOTICE

Damages to material or functional impairment due to

welding

Welding on the chassis may damage the device material, or

impair device functions.

►Before you start welding, disconnect all connections be-

tween the device and the electric system of the vehicle.

►Protect the device from flying sparks and welding beads

(splatter).

►Do not touch the device with the welding electrode or

earth clamp.

NOTICE

Dirt and moisture can affect the electrical connections

►Protect unused pins using blanking plugs.

►Protect all electrical connections with appropriate single

wire seals.

►Clean the area around a connector prior to removing the

mating connector.

Jetter AG Mechanical installation | 5

User Manual – JVM-104-O08 15

5.1 Requirements for the installation location

The installation location must meet the following requirements:

■The installation location must allow air to circulate.

■The installation location must be of sufficient size.

■The device must be easily accessible to allow for service work.

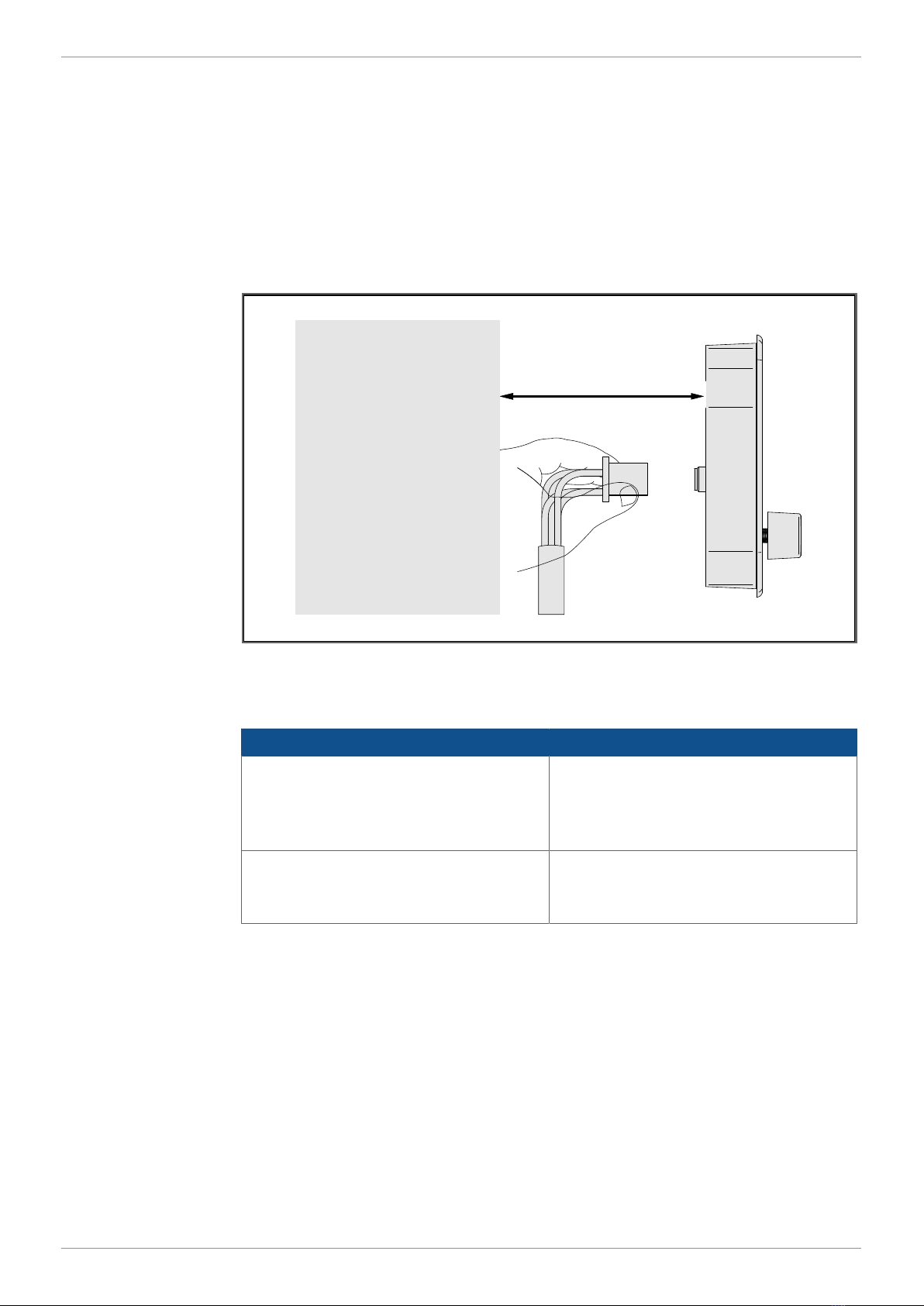

Space required for

installation and

service

It should be possible to disconnect the connectors at any time.

70

Fig.4: Space requirements for installation work (in mm)

Avoiding unsuitable

installation locations The following installation locations are unsuitable for mounting the device:

Unsuitable installation location Reason

Outdoor installation The device must not be exposed to

rain or a jet of water. Do not use a

steam jet or other such devices to

clean the device.

Installation location close to heat-sen-

sitive materials

The materials could become warped

or misshapen as a result of heat pro-

duced by the device.

Tab.12: Unsuitable installation locations

Jetter AG Mechanical installation | 5

User Manual – JVM-104-O08 16

5.2 Preparing for installation

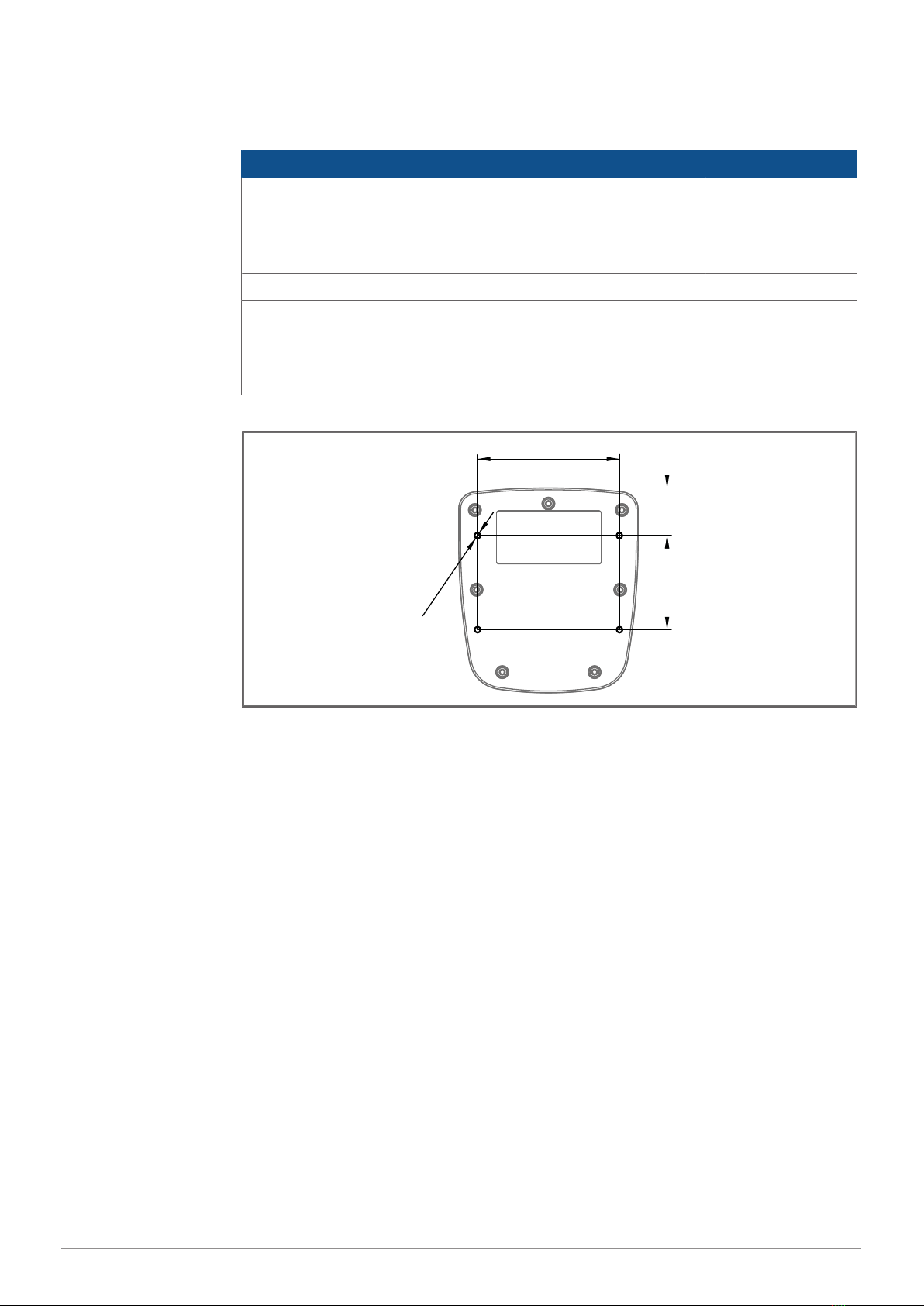

Mounting

accessories Use the following accessories for installation:

Accessories Item number

Mounting plate for RAM Mount ball

consisting of mounting plate and screws for housing with

Deutsch or M12 connector, without RAM Mount attach-

ments

10001621

OR

Mounting plate for RAM mount arm with suction cup

consisting of mounting plate and screws for housings with

Deutsch/M12 connector including RAM Mount arm with

suction cup

10001551

Screw holes

27.955

83

O3.1

4 x

Fig.5: Screw holes, dimensions in mm

Jetter AG Mechanical installation | 5

User Manual – JVM-104-O08 17

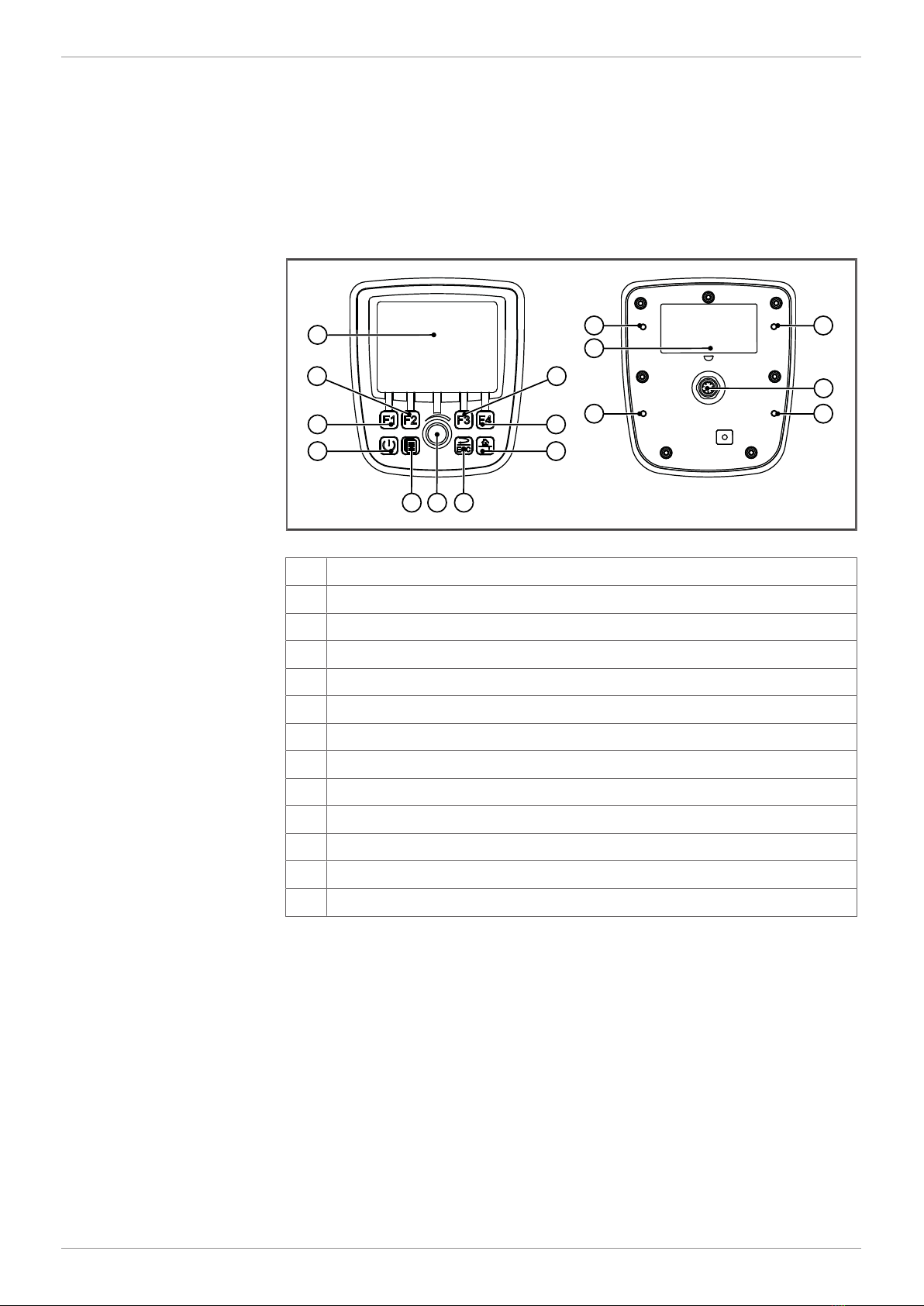

5.3 Installing the HMI

The illustration below shows how to install the device:

234

5

1

6

Fig.6: Installation drawing

1 2 x self-locking nuts

2 4 x screw for fixing to the JVM-104-O08

3 RAM Mount ball

4 Mounting plate with opening for connector

5 2 x countersunk screws for mounting a RAM Mount ball

6 Alternate position of the RAM Mount ball

1. Screw the desired RAM Mount attachments onto the mounting plate.

2. Hold the JVM-104-O08 against the mounting plate from behind. The connec-

tors must be accessible through the openings in the mounting plate.

3. Screw the mounting plate onto the JVM-104-O08.

Jetter AG Mechanical installation | 5

User Manual – JVM-104-O08 18

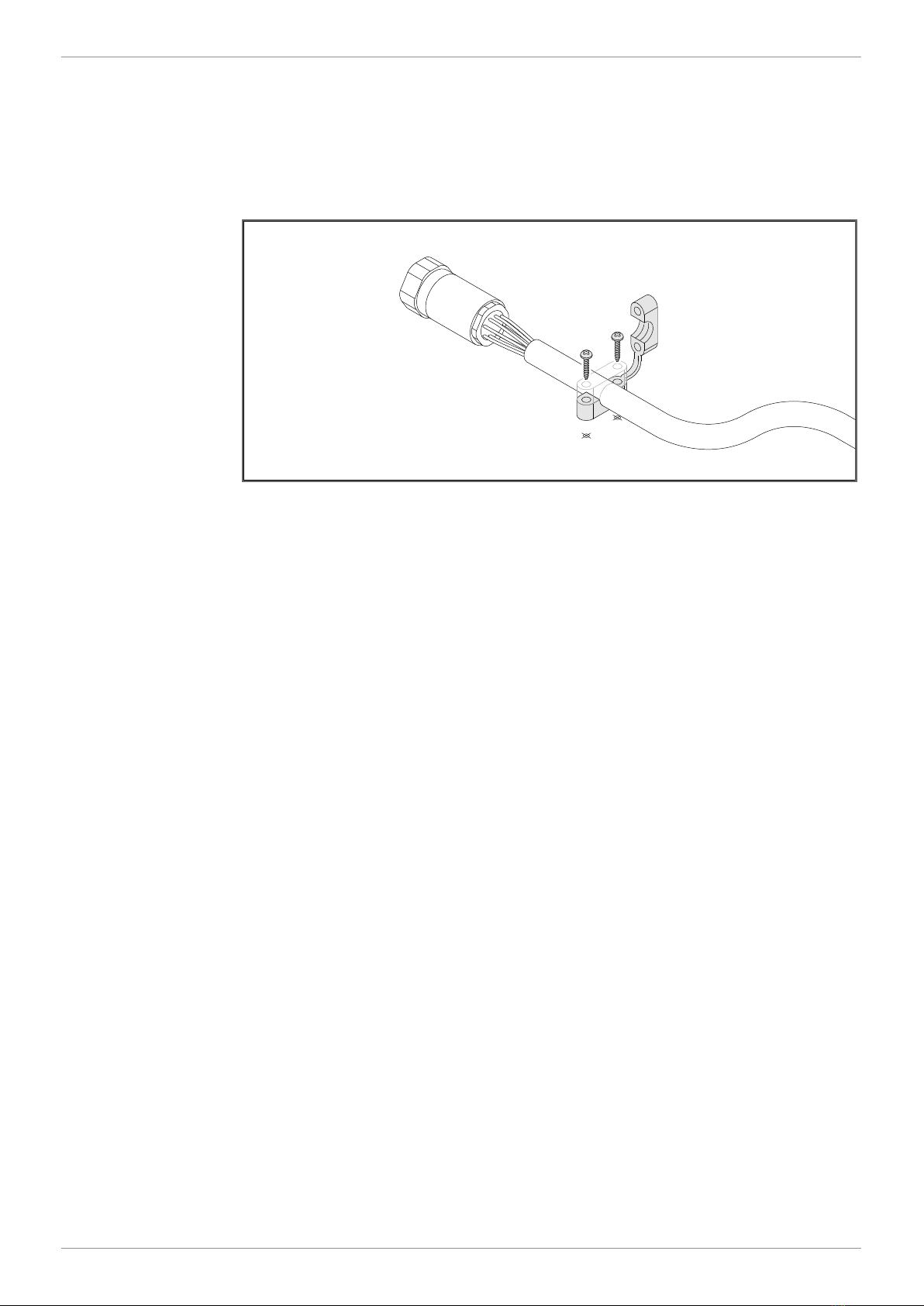

Installing the strain

relief Install strain reliefs for the connecting cables.

■Ensure that there is sufficient clearance between the strain reliefs and the

connectors.

■Connectors must not be obstructed, so that they can be removed in the

event of service.

Fig.7: Installing the strain relief

Jetter AG Electrical connection | 6

User Manual – JVM-104-O08 19

6 Electrical connection

NOTICE

Damages to material or functional impairment

Improper implementation of the wiring harness may cause

mechanical stress.

►Protect the cables from bending, twisting or chafing.

►Install strain reliefs for the connecting cables.

NOTICE

Surges resulting from missing protection or fusing

Surges may cause malfunctions or damage to the product.

►Protect the voltage inputs from surges according to the

requirements.

►Ensure that the device is handled in accordance with

ESD regulations.

Jetter AG Electrical connection | 6

User Manual – JVM-104-O08 20

6.1 Pin assignment

6.1.1 M12 male connector – voltage supply, CAN, ignition

Function The M12 connector has the following function:

■Power supply to the JVM-104-O08

■CANopen bus interface: CAN 1

■Recognition of the ignition signal

INFO Ignition

To launch the JVM-104-O08, pin 3 (Ignition+) must be con-

nected with pin 1. The ignition control signal (Ignition+) is is-

sued when the key is in position

Ignition ON

.

INFO Current consumption

When the device is energized, the current consumption is

temporarily higher. To ensure a reliable start-up of the device,

provide at least 3 times the typical current required.

1

2

3

5

4

6

7

8

Fig.8: 8-pin M12 male

connector

Pin Signal

1VBAT_ECU

2n. c.

3IGN (ignition)

4n. c.

5CAN_L

6GND

7CAN_H

8SHLD

Mating part The following jack is a mating part to the 8-pin M12 connector:

Parameter Description

Manufacturer e.g. BELDEN Lumberg automation

Manufacturer's item no. RKCN 8/9

Wire size range 0.5mm2 (AWG 20)

Tab.13: Compatible M12 connector (female)

Other manuals for JetViewMobile 104

2

This manual suits for next models

1

Table of contents

Other Jetter Recording Equipment manuals